SAF® 2507 is a super-duplex (austenitic-ferritic) stainless steel for OCTG downhole applications.

The grade is characterized by:

- High resistance to stress corrosion cracking (SCC) in chloride-bearing environments

- Moderate resistance to SCC in sour (H2S/Cl-) environments

- Excellent resistance to pitting and crevice corrosion

- High resistance to general corrosion

- Very high mechanical strength

- High resistance to erosion corrosion and corrosion fatigue

- UNS: S32750

- EN Number: 1.4410

- EN Name: X 2 CrNiMoN 25-7-4

- SS: 2328

Product standards

Seamless tubes used as casing, tubing and coupling stock:

- ISO 13680, PSL-1 and PSL-2

- API spec 5CRA, PSL-1 and PSL-2

Approvals

- NACE MR0175/ISO 15156 (Petroleum and natural gas industries - Materials for use in H2S-containing Environments in oil and gas production - Part 3: Cracking-resistant CRAs (corrosion resistant alloys and other alloys) (Published:2015)

- SAF 2507 grade 80 ksi, 90 ksi, 110 ksi, and 125 ksi, (PSL-1 or PSL-2) and grade 140 ksi (PSL-1) can be delivered with API-5CRA Monogram (License Number 5CRA-0016)

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Mo | N |

|---|---|---|---|---|---|---|---|---|

| ≤0.03 | ≤0.8 | ≤1.2 | ≤0.025 | ≤0.015 | 25 | 7 | 4 | 0.3 |

Applications

SAF® 2507 is used for high strength downhole production tubing, casing, and liners in sour gas wells. This includes environments with high temperatures, high partial pressures of CO2 and H2S, and high chloride concentrations. The material is suitable for use in production tubing and flowlines for the extraction of oil and gas from sour wells, in refineries and in process solutions contaminated with chlorides.

The high strength of SAF® 2507 makes the material an attractive alternative to the austenitic steels in structures subjected to heavy loads.

Corrosion resistance

Pitting Corrosion

SAF® 2507 can withstand high temperatures in aggressive environments without pitting. A recognized method of ranking a material's susceptibility to localized corrosion is by means of the PRE number (Pitting Resistance Equivalent). This PRE number is based on the contents of chromium, molybdenum and nitrogen in the alloy according to the following formula:

PRE = %Cr + 3.3 × %Mo + 16 × %N

A PRE number is the relative measure of a material's ability to resist pitting corrosion in chloride containing environments. The PRE number for SAF® 2507 is compared with other materials in the following table:

| Grade | % Cr | % Mo | % N | PRE |

| SAF® 2507 | 25 | 4 | 0.3 | >42.5 |

| UNS S31803 | 21.0 - 23.0 | 2.50 - 3.50 | 0.08 - 0.20 | >30 |

| Alloy 825 | 20 | 2.6 | - | 29 |

| ASTM TP317L | 18 | 3.5 | - | 30 |

| ASTM TP316L | 17 | 2.2 | - | 24 |

SAF® 2507 has a minimum PRE number of 42.5, which confirms its high resistance to pitting corrosion when chlorides are present.

Stress Corrosion Cracking (SCC)

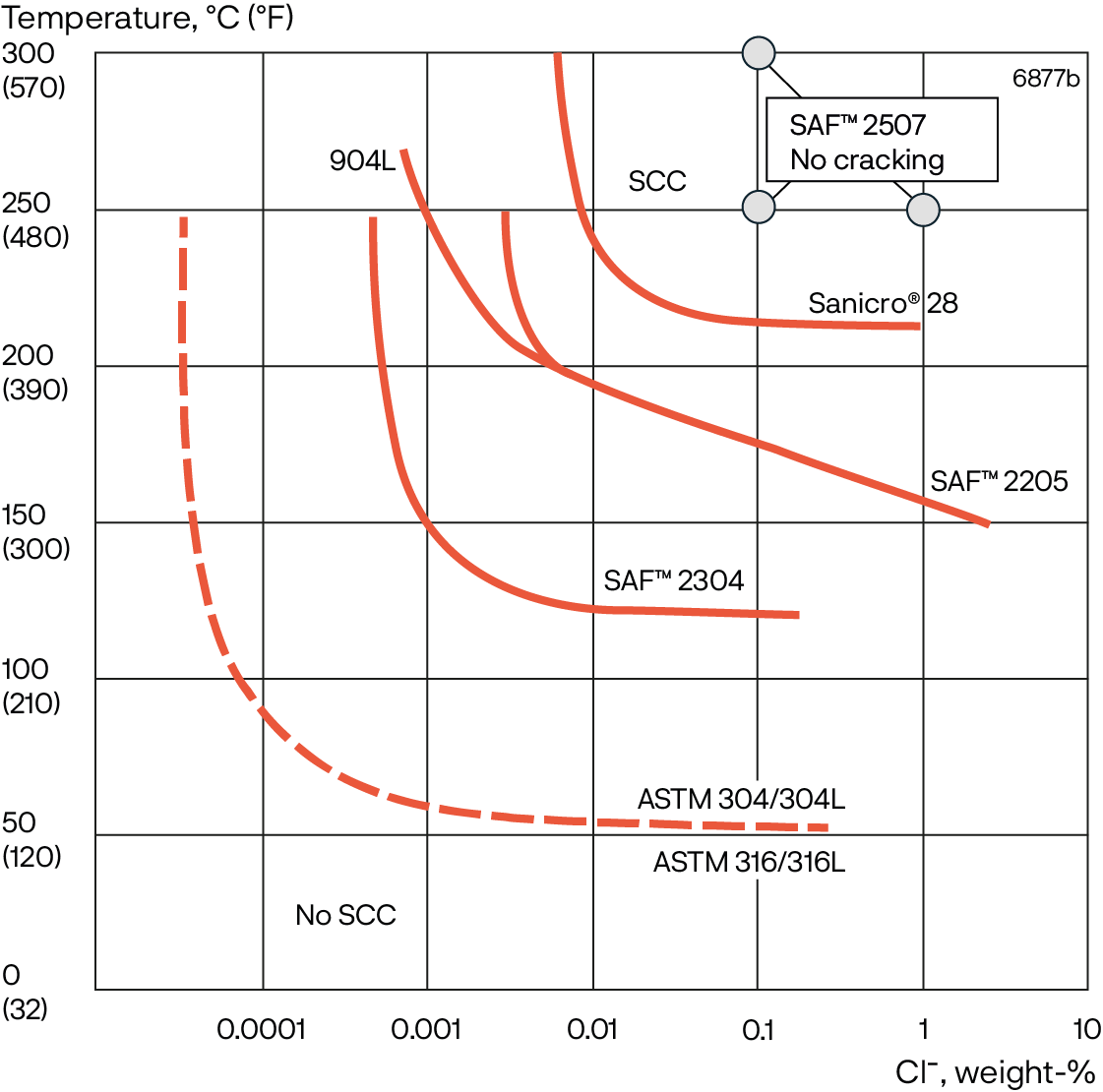

SAF® 2507 has excellent resistance to chloride induced stress corrosion cracking (SCC). The SCC resistance of SAF® 2507 in chloride solutions at high temperatures is illustrated in Figure 13. There were no signs of SCC up to 1000 ppm Cl-/300°C and 10000 ppm Cl-/250°C. SAF® 2507 U-bend specimens exposed for 1000 hours in hot brine (108°C, 226°F, 25% NaCl) showed no cracking.

Figure 13. SCC resistance in oxygen-bearing (abt. 8 ppm) neutral chloride solutions. Testing time 1000 hours. Applied stress equal to proof strength at testing temperature.

Fabrication

SAF® 2507 tubes are supplied in the cold worked condition and are intended for use with threaded connections.

Forms of supply

Materials for oil and gas production

For production tubing, casing, liner, and coupling stock for downhole oil and gas applications, SAF® 2507 is supplied solution annealed (80 ksi, 90 ksi) or cold hardened with high strength properties (110 ksi, 125 ksi, 140 ksi).

Full details on sizes, finishes and mechanical properties are available on request. Email: stog.smt@alleima.com

Mechanical properties

At 20°C (68°F)

Metric and imperial units

| Grade | Proof strength | Tensile Strength | Elongation | Hardness | ||

| Rp0.2a) | Rm | A2” | HRC | |||

| MPa | ksi | MPa min | ksi min | % min | % max | |

| PSL-1 SAF2507-80 | 552 - 724 | 80 - 105 | 758 | 110 | 20 | 28 |

| PSL-1 SAF2507-90 | 621 - 724 | 90 - 105 | 793 | 115 | 20 | 30 |

| PSL-1 SAF2507-110 | 758 - 965 | 110 - 140 | 862 | 125 | 12 | 36 |

| PSL-1 SAF2507-125 | 862 - 1034 | 125 - 150 | 896 | 130 | 10 | 37 |

| PSL-1 SAF2507-140 | 965 - 1103 | 140 - 160 | 1000 | 145 | 9 | 38 |

| PSL-2 SAF2507-80 | 552 - 724 | 80 - 105 | 758 | 110 | 20 | 28 |

| PSL-2 SAF2507-80 | 621 - 724 | 90 - 105 | 793 | 115 | 20 | 30 |

| PSL-2 SAF2507-110 | 758 - 965 | 110 - 140 | 862 | 125 | 12 | 36 |

| PSL-2 SAF2507-125 | 862 - 1000 | 125 - 145 | 896 | 130 | 10 | 36 |

1 MPa = 1 N/mm2

a) Rp0.2 corresponds to 0.2% offset yield strength.

At high temperatures

SAF® 2507 shows very good mechanical properties at higher temperatures. Further information is available on request. Email: stmo.smt@alleima.com

Metric units / Imperial units

| Temperature °C | De-rating factor* | Temperature °F | De-rating factor* |

| 20 | 1.00 | 68 | 1.00 |

| 50 | 0.96 | 122 | 0.96 |

| 100 | 0.87 | 212 | 0.87 |

| 150 | 0.81 | 302 | 0.81 |

| 200 | 0.76 | 392 | 0.76 |

Physical properties

Density, at 7.8 g/cm3, 0.28 lb/in3

Thermal conductivity

Metric units

| Temperature,°C | 20 | 100 | 200 | 300 | 400 |

| W/(m °C) | |||||

| SAF® 2507 | 14 | 15 | 17 | 18 | 20 |

| ASTM TP316L | 14 | 15 | 17 | 18 | 20 |

Imperial Units

| Temperature,°F | 68 | 200 | 400 | 600 | 800 |

| Btu/(ft h °F) | |||||

| SAF® 2507 | 8 | 9 | 10 | 11 | 12 |

| ASTM TP316L | 8 | 9 | 10 | 10 | 12 |

Specific Heat Capacity

Metric units

| Temperature,°C | 20 | 100 | 200 | 300 | 400 |

| J/(kg °C) | |||||

| SAF® 2507 | 490 | 505 | 520 | 550 | 585 |

Imperial Units

| Temperature,°F | 68 | 200 | 400 | 600 | 800 |

| Btu/(lb °F) | |||||

| SAF® 2507 | 0.12 | 0.12 | 0.13 | 0.13 | 0.14 |

Thermal Expansion

Metric units, x10-6/°C

| Temperature, °C | 30-100 | 30-200 | 30-300 | 30-400 |

| Per °C | ||||

| SAF® 2507 | 13.5 | 14.0 | 14.0 | 14.5 |

| Carbon steel | 12.5 | 13.0 | 13.5 | 14.0 |

| ASTM TP316L | 16.5 | 17.0 | 17.5 | 18.0 |

Imperial units, x10-6/°F

| Temperature, °F | 86-200 | 86-400 | 86-600 | 86-800 |

| Per °F | ||||

| SAF® 2507 | 7.5 | 7.5 | 8.0 | 8.0 |

| Carbon steel | 6.8 | 7.0 | 7.5 | 7.8 |

| ASTM TP316L | 9.0 | 9.5 | 9.8 | 10.0 |

Resistivity

Metric units

| Temperature, °C | 20 | 100 | 200 | 300 |

| μΩm | ||||

| SAF® 2507 | 0.83 | 0.89 | 0.96 | 1.03 |

Imperial units

| Temperature, °F | 68 | 200 | 400 | 600 |

| µΩin | ||||

| SAF® 2507 | 32.7 | 34.9 | 37.9 | 40.7 |

Modulus of elasticity

Metric units, x103

| Temperature, °C | 20 | 100 | 200 | 300 |

| MPa | ||||

| SAF® 2507 | 200 | 194 | 186 | 180 |

Imperial units, x103

| Temperature, °F | 68 | 200 | 400 | 600 |

| ksi | ||||

| SAF® 2507 | 29.0 | 28.2 | 27.0 | 26.2 |

Impact Strength

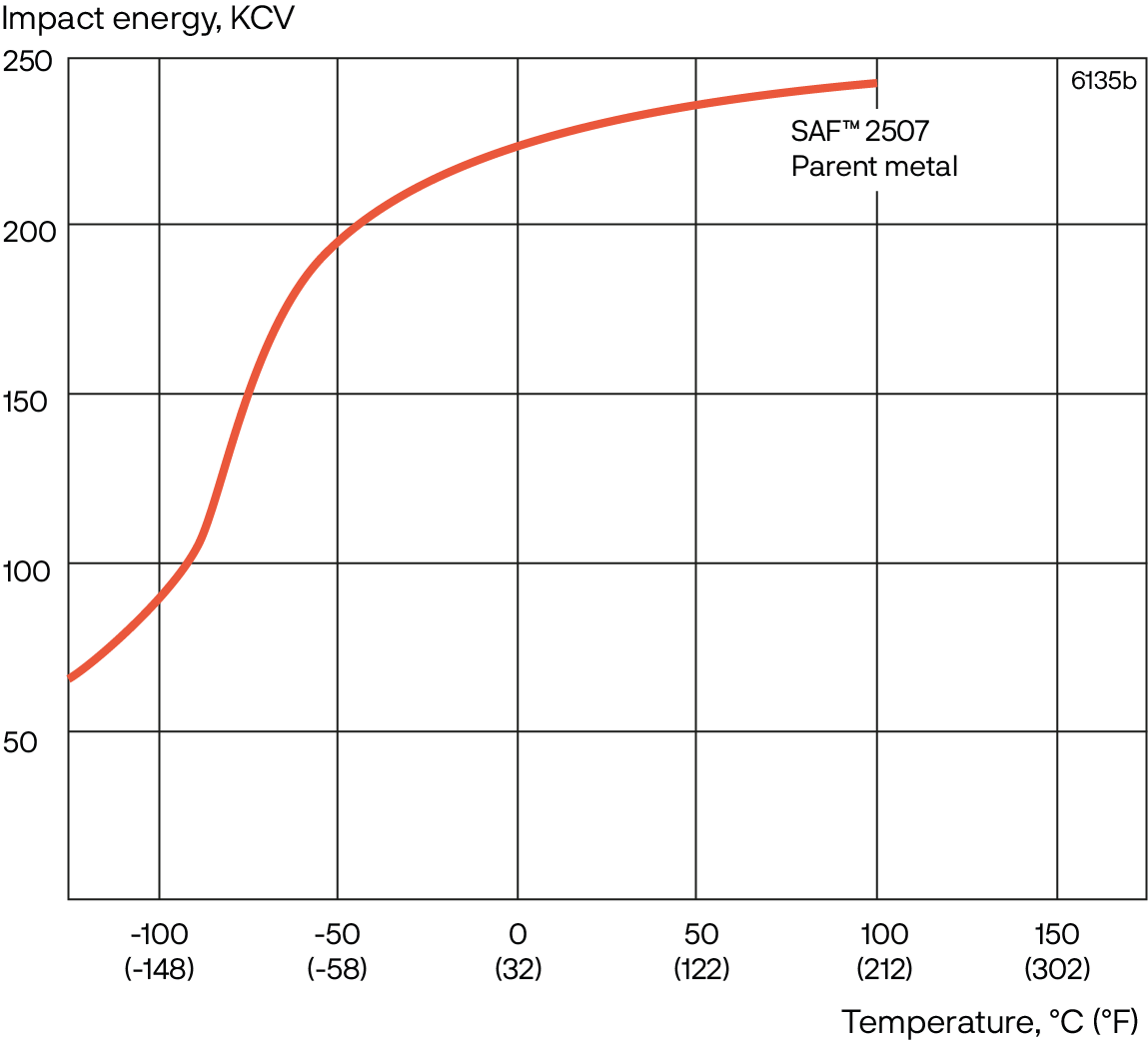

SAF® 2507 possesses good impact strength. The ductile brittle transition temperature is below -50°C (-58°F).

Figure 2. Typical impact energy curve for SAF® 2507 using Charpy V specimens (average of 3 at each temp.). Parent metal samples taken in the longitudinal direction from 260 x 12mm hot extruded and solution annealed (1075°C / 1965°F) tube.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.