What

Nickel alloys for the heliostats at the top of a solar tower.

How

Solar may be hotter than ever, but it’s not without its challenges. The use of molten salt for heat transfer, in combination with high temperatures, leads to highly corrosive conditions. This results in a need for advanced heat- and corrosion-resistant alloys. Our stainless steel and nickel alloys are suitable for these kinds of conditions.

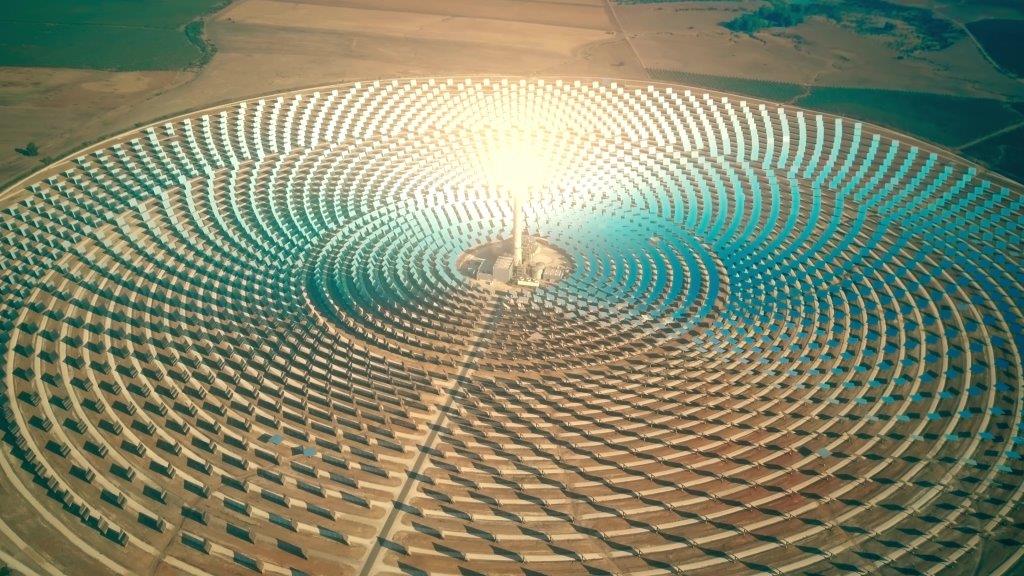

A solar tower uses heliostats to reflect and concentrate the rays of sun onto a central receiver placed at the top of a fixed tower. In the central receiver, heat is absorbed by a heat transfer fluid, which then transfers the heat to a heat exchanger to produce steam that powers a steam turbine. Due to the mix of very high temperatures and corrosive heat transfer fluids, nickel alloys are a suitable material choice for this application.

Why

The sun’s energy is limitless and could potentially power the entire planet – if harnessed correctly. As regulators around the world seek to decarbonize and electrify the future energy supply, the solar sector is growing exponentially.

Solar power plants harness energy either in photovoltaic (PV) cells or thermally in concentrated solar power (CSP) systems. There are four main CSP technologies: parabolic trough, solar tower, linear fresnel, and parabolic dish. Each of these technologies comes with its own set of material challenges, from elevated temperatures to highly corrosive environments.

Our tubular products are ideally suited for use in the challenging concentrated solar power environment. Click here to find out why >>