SAF 2507™ LHP for laying head pipe is a high alloy super-duplex stainless steel.

Main characteristics of SAF 2507 LHP

- Very high mechanical strength

- Excellent wear resistance at high temperatures

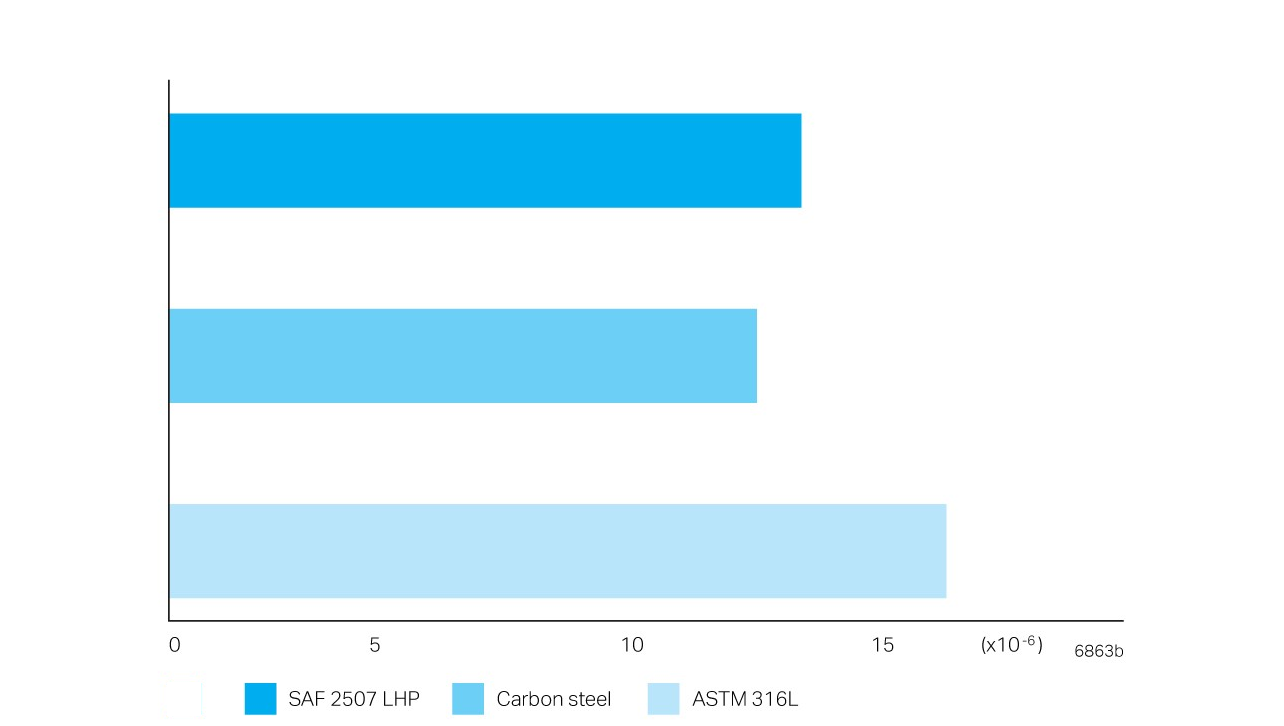

Thermal expansion

SAF™2507 LHP has a coefficient of thermal expansion close to that of carbon steel. This gives SAF™ 2507 LHP definite design advantages over austenitic stainless steels in equipment comprising both carbon steel and stainless steel. The values given below are average values in the temperature ranges.

Metric units x10-6/°C

| Temperature, °C | 30-100 | 30-200 | 30-300 | 30-400 |

| SAF™ 2507 LHP | 13.5 | 14.0 | 14.0 | 14.5 |

| Carbon steel | 12.5 | 13.0 | 13.5 | 14.0 |

| ASTM 316L | 16.5 | 17.0 | 17.5 | 18.0 |

Figure 1. Thermal expansion comparison between grades.

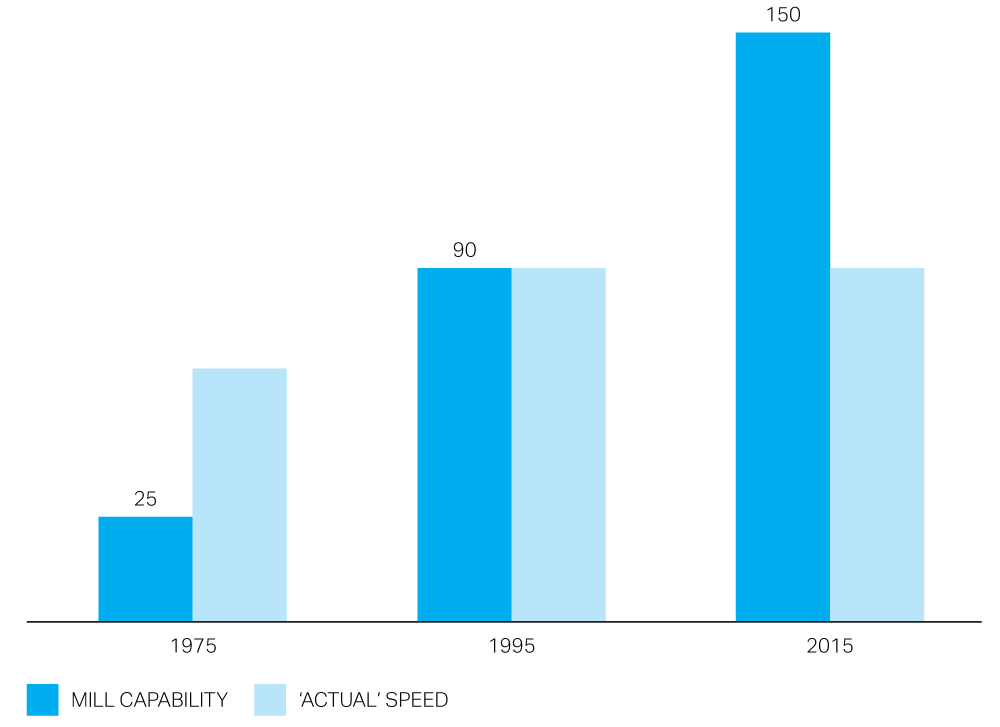

Modern mills

Historic development

- Rolling rods of OD 5,5 mm at speeds up to 150 m/s (this requires LHP with ID ≈ 20 mm)

- LHP with reduced bore sized (ID ≈ 20 mm) should be used for small diameter products (OD = 4 ÷ 12 mm) for a more consistent pattern

Historic development of 5.5 mm wire rod rolling speed, mill capability (m/s)

Figure 2. Forced productivity, sub-optimization.

Common problems

- Higher rolling speeds → acceleration of pipe wear

- LHP wear → unstable laying ring pattern

- Possibility of wire breaking in pipe ("cobble")

- Wire rod produced with inconsistent mechanical properties and tolerances