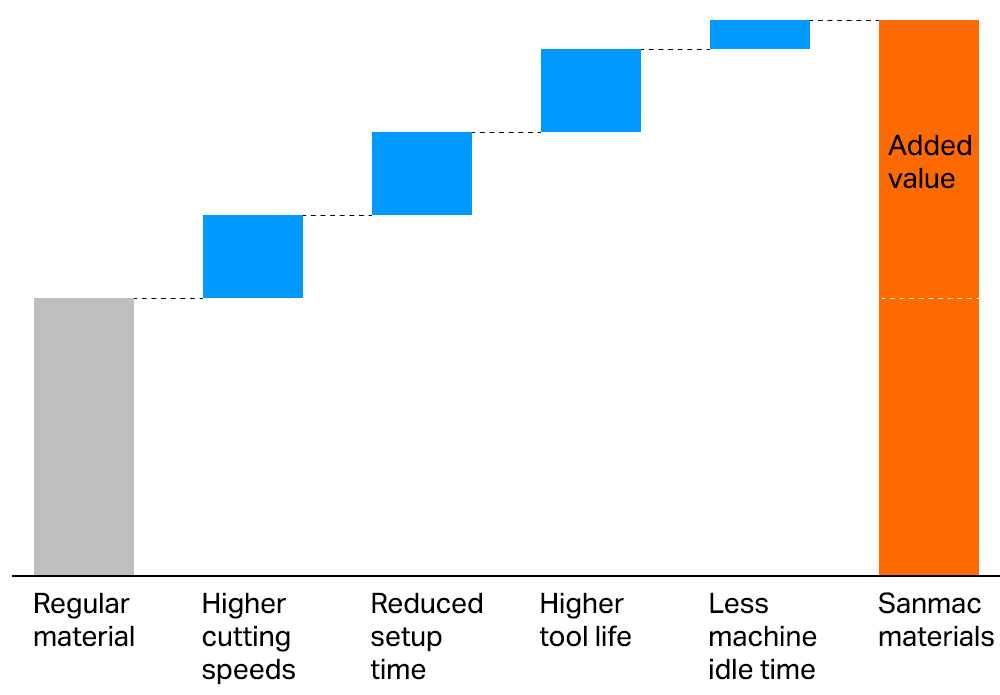

On average, a machine tool will utilize 24% of the available time during a calendar year adding value and generating profits. Around 36% of that time is spent setting up the machine tool and running trials to establish standard cutting data to suit the material behavior.

Graph showing production time distribution

To maximize the value-adding time and to reduce the setup and tooling time, it is important to have quality and consistency in both component and tooling materials.

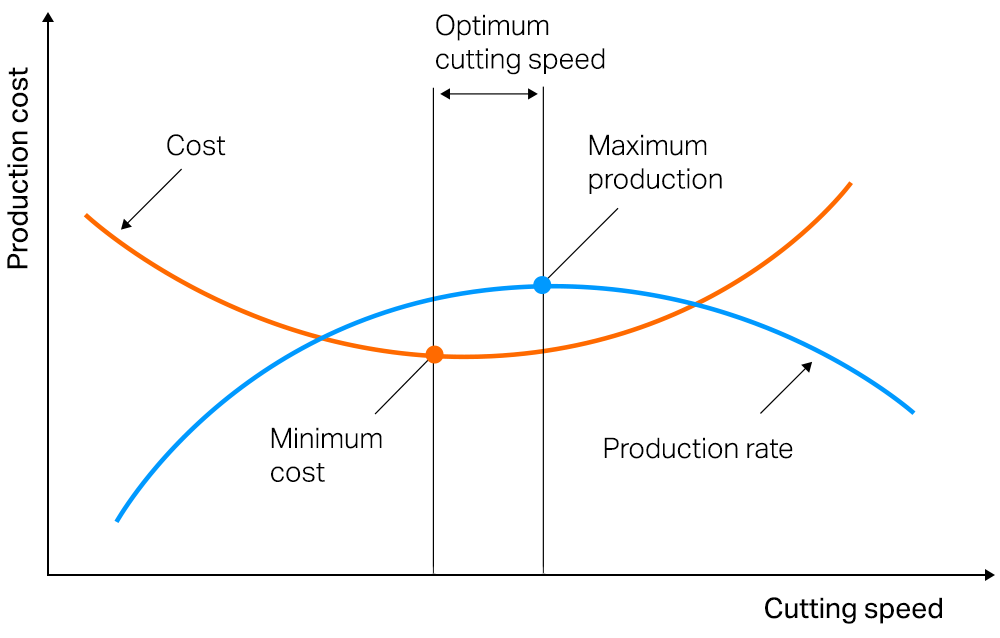

Each raw material will behave differently during machining, based on chemical composition and microstructure. Using the right combination of cutting tools and cutting data, an optimal cutting speed can be determined, to maximize production and minimize cost.

Production cost vs. cutting time

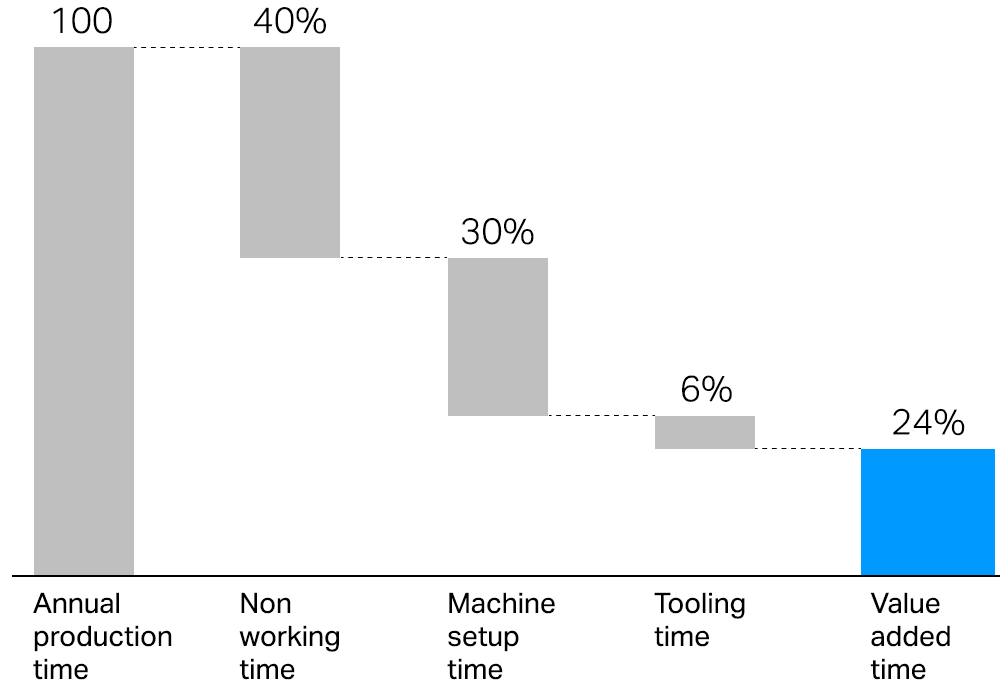

With our extensive knowledge and continuous research in both raw materials and cutting tools, we developed Sanmac® materials, which are produced with tight tolerances and consistent chemical composition and microstructure.

Added value using Sanmac® materials

Consistent behavior during a machining operation allows component manufacturers to establish the optimal cutting speed more quickly. And repeat the same cutting data between different batches of materials.