It is obviously difficult to check the hardening results without destroying the knife blade. The only test that can be done relatively simply is to assess the hardness of the steel, but this only provides an indication of how the material has been hardened. It is therefore extremely important to follow the hardening instructions as regards to the times and temperatures of the various operations.

To make certain that the material also has the correct structure, toughness, adequate corrosion resistance and an appropriate quantity of retained austenite, a knife blade should be sent to the test laboratory at regular intervals for examination.

If the straightness or flatness of the knife blades is found to need adjustment after quenching, this is best done before the material is tempered, at least before it has had time to cool to room temperature.

Re-hardening is not recommended, since it seldom produces good results. But if this is necessary for any reason, it is advisable to lower the hardening temperature by about 10°C (50°F) below normal. However, larger batches can be hardened as usual.

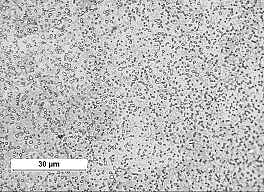

Optimum hardening produces an unstructured matrix of tempered martensite with very small, uniformly distributed carbides, and a certain amount of residual austenite. The content of retained austenite should be between 5 and 15% (see the picture below).