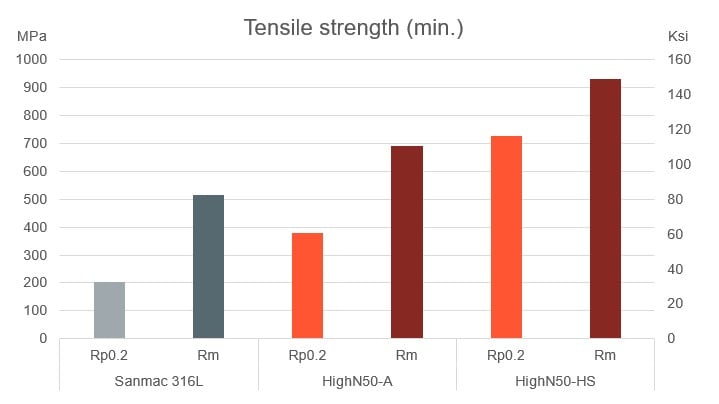

Alleima® HighN50 is a high-strength, non-magnetic austenitic stainless steel strengthened by nitrogen in a stable Z-phase. It delivers an exceptional combination of mechanical strength and corrosion resistance, enabling reliable performance in demanding environments.

Menu

- Home

-

Products

- Wire-based solutions

-

Tube & pipe

- Advancing American Industry through materials technology

- Alleima's new tube production facility, Zhenjiang, China

- Articles

- E-Track

- Tradeshows

- Technical services

- Approvals and standards

- Stock program

-

Tubular products

- Zirconium tubes

- Umbilical tubes

- Titanium tubes

- Thermocouple tubes

- Superheater tubes

- Subsea tubes

- Stripper tubes

- Steam generator tubes

- Scrubber tubes

- Riser tubes

- Reheater tubes

- Recuperator tubes

- Production tubing (OCTG)

- Precision tubes

- Nuclear steam generator tubing

- Nuclear fuel tubes

- Nitric acid tubes

- Muffle tubes

- Medical tubes

- Mechanical tubing

- Laying head pipe

- Lance tubes

- ISO/EN tubes

- Hydraulic and instrumentation tubing

- High-temperature tubes

- High-pressure tubes

- Heat exchanger tubes

- GDI and CNG fuel system tubes

- Furnace tubes

- Flowline piping

- Finned tubes

- Evaporator tubes

- Ethylene furnace tubes

- Downhole casing

- Control lines

- Condenser tubes

- Composite tubes

- Coiled tubing

- Chemical injection lines for demanding energy applications

- Capillary tubes

- Boiler tubes

- Bimetallic tubes

- ASME/ASTM welded pipe

- ANSI/ASME pipe

- Aerospace tubes

-

High-performance materials

- 1250°C heat protection for mineral insulated cables

- Sanicro® 35 Bridges the Gap Between Stainless Steels and Nickel Alloys for Chemical and Refinery Industries

- SAF™ 3007

- SAF™ 3006

- Sanicro 35

- Titanium and zirconium

- SAF™ 2906: Our latest addition for the Urea Industry with enhanced corrosion resistance

- Clean H&I tubing for trouble-free systems

- Alleima® 3R60: advancing the standards for corrosion resistance

- Sanmac® stainless steels

- Sanicro® 28

- Alleima® 2RE10

- Alleima® 2RE69

- Safurex®

- High-temperature stainless steels

- Duplex stainless steels

- List of alloys

-

Strip steel

- Compressor valve steel

- Steel for razors

- Doctor blade steel

-

Knife steel

- Outdoor knife steel

- Industrial applications

- Kitchen knives

- Damax™ damascus steel

- Knife steel knowledge

- Size range

- Mechanical properties

- Material selection table

- Our knife steels

-

Hardening guide

- Purpose of hardening and tempering

- The hardening procedure

-

Hardening programs

- Alleima® 7C27Mo2 piece hardening

- Alleima® 7C27Mo2 batch hardening

- Alleima® 19C27 piece hardening deep freezing -70°C/95°F

- Alleima® 19C27 piece hardening

- Alleima® 19C27 batch hardening deep freezing -70°C/-95°F

- Alleima® 19C27 batch hardening

- Alleima® 14C28N piece hardening deep freezing -70°C/-95°F

- Alleima® 14C28N piece hardening deep freezing -20°C/-5°F

- Alleima® 14C28N piece hardening

- Alleima® 14C28N batch hardening deep freezing -70°C/-95°F

- Alleima® 14C28N batch hardening deep freezing -20°C/-5°F

- Alleima® 14C28N batch hardening

- Alleima® 13C26 piece hardening deep freezing -70°C/-95°F

- Alleima® 13C26 piece hardening

- Alleima® 13C26 batch hardening deep freezing -70°C/-95°F

- Alleima® 13C26 batch hardening

- Alleima® 12C27M piece hardening -20°C/-5°F

- Alleima® 12C27M piece hardening

- Alleima® 12C27M batch hardening deep freezing -20°C/-5°F

- Alleima® 12C27M batch hardening

- Alleima® 12C27 piece hardening deep freezing -70°C/-95°F

- Alleima® 12C27 piece hardening deep freezing -20°C/-5°F

- Alleima® 12C27 piece hardening

- Alleima® 12C27 batch hardening deep freezing -70°C/-95°F

- Alleima® 12C27 batch hardening deep freezing -20°C/-5°F

- Alleima® 12C27 batch hardening

- Spring steel

- Shock absorber strip steel

- Medical strip steel

- Size tolerances

- Shape

- Edges

- Surfaces

- List of alloys

- Alloy surcharges

- Distributors

- Plate and sheet

- Furnace products and heating systems

- Coated Strip Steel

- Billets and blooms

- Solid bar and hollow bar

- Alloy surcharges

- Fittings & flanges

-

Technical center

- Certifications

- Corrosion tables

- Corrosion knowledge

- Safety information sheets (SIS)

- Welding guide

- Shielding the weld

- Material datasheets

- Pressure calculations

-

Whitepapers

- Download whitepaper - Steel selection guide

- Download whitepaper - Specialised uses of thermocouple wire in medical devices

- Download whitepaper - Nitinol and its transformative role in medical devices

- Download whitepaper - The design potential of compressors through next-generation valve material

- Download whitepaper - Remote patient monitoring

- Download whitepaper - A cut above

- Download whitepaper - Sensors and remote monitoring

- Download whitepaper - Medical metals and coatings

-

Webinars

- O&G Applications: Technical Benefits of a Seamless Control Line for Downhole Webinar 2

- Corrosion Resistant Alloys for Heat Exchanger in the Chemical Process Industry(2)

- O&G Applcations: Technical Benefits of a Seamless Control Line for Downhole

- The Duplex Stainless Steel Webinar Series: Get the best of both worlds

- Carbon Capture, Utilization, and Storage: Introduction to Material Selection Webinar

- Carbon Capture, Utilization, and Storage: Introduction to Material Selection Webinar

- Captura, Utilização e Armazenamento de Carbono : Uma Introdução a Seleção de Materiais

- Fertilizer Applications: Corrosion Resistant Material Selection

- Corrosion Resistant Alloys for Heat Exchanger in the Chemical Process Industry

- Sanicro 35: Bridging the Gap Between Stainless and Nickel Alloys for Refinery Applications

- Careers

- Contact

- Investors

- News & media

- About us

- Sustainability

- Innovation & insights

-

Campaigns

- Introducing the next generation of super-duplex materials

-

900 ways to make a change

- Electric heating reducing climate impact

- Electric heat treatment for Ovako

- Sanergy™ LT brings fuel cells for the future

- Energy efficiency improvements with Freeflex™

- Life-changing solutions with Alleima® medical wire

- Supporting the expansion of hydrogen infrastructure

- Solar towers to power the future

- Supercritical water gasification – a promising renewable technology

- Hidden heroes of industry

- Change language