Enhancing capabilities, Fueling industries

Alleima Tube Zhenjiang’s Phase II expansion marks a major milestone in our journey to deliver advanced tubular solutions for most demanding industries in China and rest of Asia.

It unveils our expanded production capabilities, including composite tubes, high-temperature tubing, heat exchanger tubes, high pressure tubes, and cold worked pipe. These enhancements are designed to meet growing market demands in key sectors such as chemical, petrochemical, pulp and paper, hydrogen, renewables, and medical.

Our journey

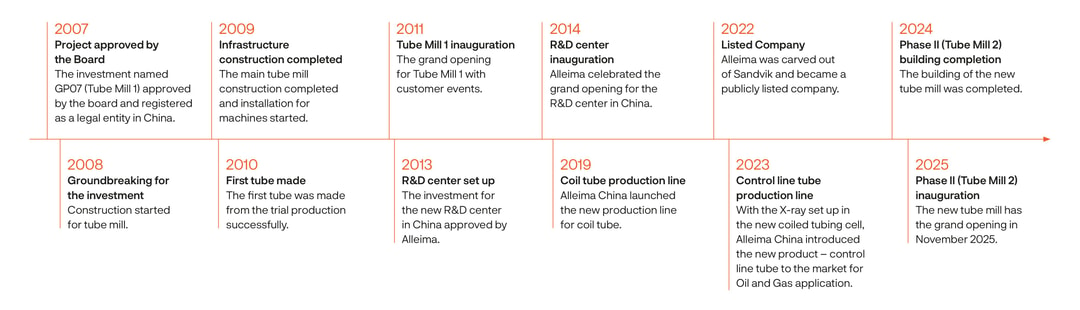

From our beginnings in Zhenjiang in 2007 to the 2025 Phase II expansion, Alleima has continuously invested in innovation and capacity to serve customers across China and rest of Asia. The new expansion builds on over four decades of experience in China, reinforcing our long-term commitment to customers and partners.

|

|

|

|

|

|

What phase II brings

Phase II adds 12,500 m² of new production space and state-of-the-art equipment, enabling a broader product portfolio and increased supply reliability