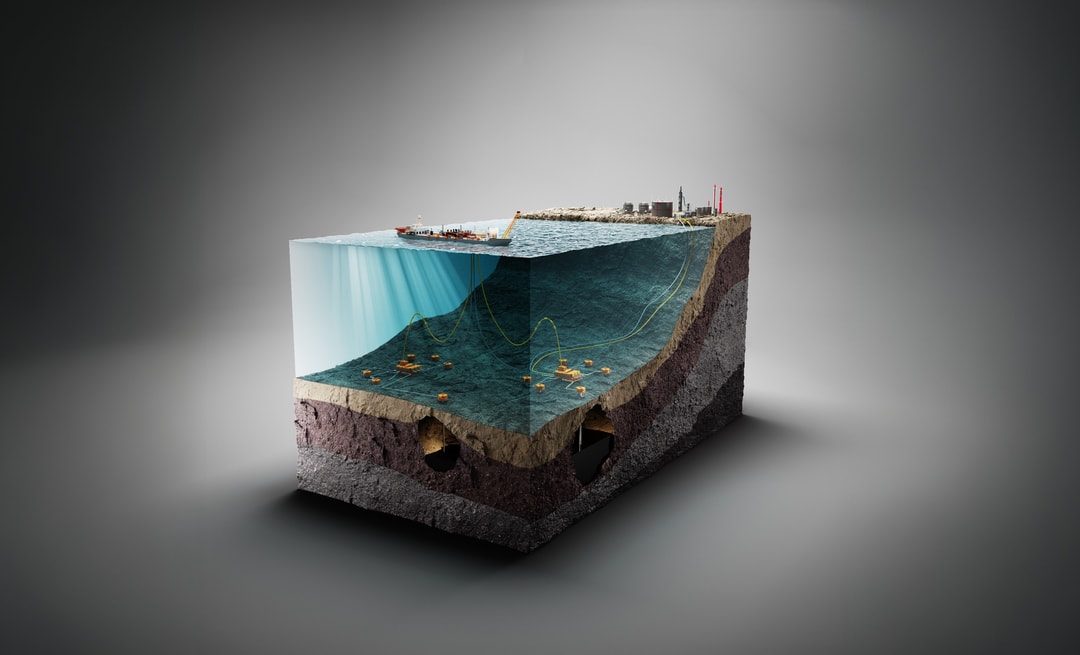

Longer tie-backs? 10,000 feet or deeper? High H2S levels? We help you get there.

This is our promise to the oil and gas industry – built on decades of experience and customer teamwork.

Since the early 1960s, we’ve supported both upstream and downstream operations. With a fully integrated production process and complete traceability, from melt to final tube, Alleima continues to set the industry standard – together with our customers.

Three core product offerings:

- Umbilical tubing

- Control line tubing

- Oil Country Tubular Goods (OCTG) tubing

World-leading experience within umbilical tubing

160,000,000 meters. Zero failures

Today, we are the market leader in the category, with our tubes in use on every continent and in all major oil fields – supplying every major umbilical manufacturer. To date, we’ve delivered over 160,000,000 meters of tube, equal to 3.5 times around the globe – with zero failures!

Rigorous quality control

All our umbilical tubes are produced in a dedicated mill in Chomutov, Chech Republic, where they are cold-worked and orbitally welded under rigorous quality control and full documentation before being coiled and delivered to umbilical fabricators.

In the 1980s, we revolutionized the market with the introduction of duplex alloys, replacing inferior solutions used at the time. Today, the super-duplex SAF™ 2507 (UNS: S32750) has become the industry standard, increasing both productivity and safety.

New SAF™ 3007 is here!

To meet future challenges – such as deeper sea depths and higher system pressures – Alleima recently introduced the next generation of umbilical tubing: SAF™ 3007 (UNS S83072). This new alloy offers many advantages, with weight reduction among the most sought-after benefits.

Best-in-class control line tubing and chemical injection line tubing

Alleima supplies control lines and chemical injection lines in austenitic and duplex stainless steels. Tubes are supplied in both seamless and welded condition, delivered in coils or straight lengths. Whatever the requirements, we offer a quick and effective solution – delivered on your own reels, coiled, flushed, filled, tested and ready to go.

Product and service combined – a perfect match

By combining high-quality tube with tailored services, we help customers boost productivity and save time. Our product offering consists of seamless coiled tubing for control lines and chemical injection lines.

- Downhole control lines: Small-diameter tubing, typically 1/4” OD, used to hydraulically control the subsurface safety valve that shuts in the well.

- Downhole chemical injection lines: Longer or slightly larger tubing, typically 3/8” – 3/4” OD, used for methanol or acid injection.

Our service offering ensures just-in-time deliveries through our dedicated Service Center in Malaysia, all maintaining stock of seamless coiled tube.

Additional services include:

- Cut to length

- Hydrotesting

- Color coding

- Encapsulation

- Flushing and filling

- Level wound on reels

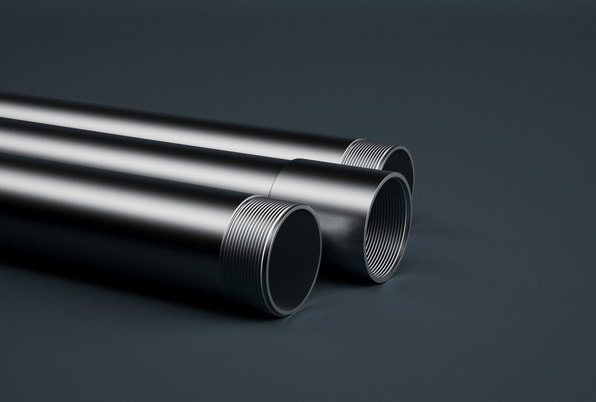

No1 in advanced alloy OCTG tubing (Oil Country Tubular Goods)

Taking on hot and sour wells

To meet the challenges of high downhole pressures and corrosive well conditions, Alleima markets a range of OCTG (Oil Country Tubular Goods). The portfolio focuses on seamless tubing, casing and coupling stock, available in sizes ranging from 2 3/8” to 9 5/8” OD, including coupling stock.

Key grades include SAF™ 2205 (UNS S32205), SAF™ 2507 (UNS S32507), Sanicro® 28 (UNS N08028), Sanicro® 29 (UNS N08029), Sanicro® 42 (UNS 08825), and Sanicro® 48 (UNS N06985).

Tenaris connections extend our value

Since 2003, Alleima has maintained a strategic partnership with Tenaris, a leading global player in the steel pipe and tubular business, particularly within the energy sector. Tenaris brings scale, global reach, technical innovation and service capability – while Alleima adds deep metallurgical expertise and fully integrated corrosion-resistant alloy (CRA) production. Together, this partnership has proven its strength and reliability on a global scale.

OCTG and Carbon Capture

Together with Tenaris, Alleima is seeing growing demand for OCTG solutions in carbon capture and storage (CCS). Storing CO2 deep underground helps cut emissions but also involves injecting supercritical fluids at high temperatures and pressures – conditions that demand the same advanced materials and expertise proven in our oil and gas portfolio.