At Alleima, we walk the talk.

At the end of last year when we introduced our express program for heat exchanger tubes we told you it would take just eight weeks from order to delivery.

Ambitious? Maybe. But you know that’s how we do things. And we’ve already got the proof to back up our promise.

We’ve just completed the first two orders for long-standing customers in Denmark and Sweden under the express hollows program. For both orders, from order to delivery, it took eight weeks. Just like we said it would.

Saving the day in Sweden

We’d only just announced our express hollows program for the EMEA region when we got our first order.

During a maintenance stop, a refinery in Sweden found chloride stress corrosion cracking in heat exchanger tubing made from the high alloyed austenitic stainless steel 904L. They needed 1.5 tons of replacement tubing quickly to avoid a very costly delay in plant start-up. However, they were looking at a lead time of up to 30 weeks to replace the tubes conventionally. They came to us for help.

Our team of sales, technical marketing, and production management worked together to come up with a) an advanced material solution that was an improvement on the existing grade and b) deliver it within our eight-week timescale guarantee.

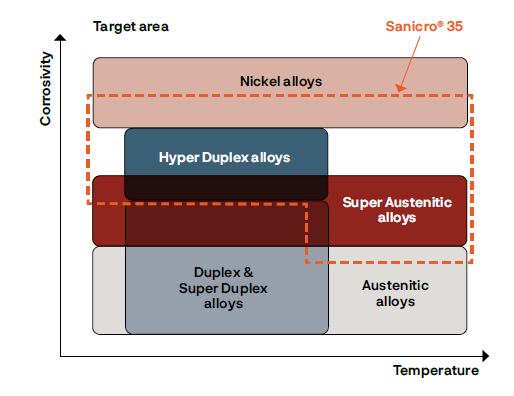

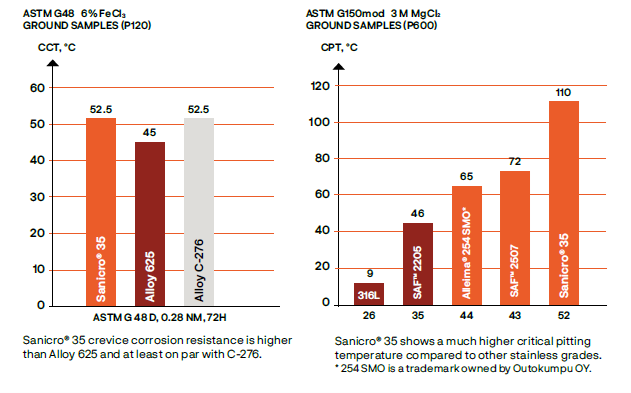

We recommended our new super-austenitic stainless steel alloy Sanicro® 35. This advanced material bridges many property gaps between stainless steel and costly nickel alloys and is designed for service in corrosive environments. With excellent resistance to pitting and crevice corrosion, and chloride induced stress corrosion cracking, and readily available in the right quantities, Sanicro® 35 was the perfect solution: an advanced material that met the customer’s tight deadline.

The table & graphs comparing Sanicro® 35 with other grades

Delivering in Denmark

At the beginning of this year, a customer in the pharmaceuticals industry in Denmark came to us with an urgent request for 1.5 tons of our super-duplex SAF™ 2507 for heat exchanger tubing for a new-build facility.

Once again, they couldn’t wait for a long delivery, so we recommended our express hollows program as an effective solution to their challenge.

And, yet again, through close collaboration between the customer, our sales team, technical marketing, and production management, the materials were good to go within eight weeks.

A progressive partner

Our express hollows program proves that we don’t just manufacture and deliver the absolute best in materials technology, but we work with our customers to find the best options suited to your business requirements, and what you need to be at your best.

“Our customers tell us that we recommend the right materials for long-lasting solutions. Our express hollows program ensures they get those solutions quickly,” says Rickard Nikander, Senior Product Manager for High Temperature and Heat Exchanger.

“Our success is based on our strong relationships with our customers and the effectiveness of our unbreakable triangle made up of our sales force, our technical marketing people, and our product management team. We’ve got the perfect team delivering the perfect start for our express hollows program.

“At Alleima, we’ve been doing what we say for over 160 years. It means our customers can trust us to deliver. When we said we could supply heat exchanger tubes within eight weeks, everyone should’ve known it would happen. It has, and now customers can benefit from the absolute best in materials technology in double quick time.”

The four grades included in the express hollows program are Sanicro® 35, SAF™ 2507, SAF™ 2205, and Alleima® 254 SMO*.

The hollows are produced at our fully integrated mill in Sandviken, Sweden. The tubes are manufactured from the Swedish hollows at our production unit in the Czech Republic. Order quantities under the express hollows program range from 1 ton to 5 tons.

Contact your local sales team for more information.

*254 SMO is a trademark owned by Outokumpu OY.