Sanicro® 35 is an alloy combining the best features of a super austenitic stainless steel and a nickel alloy. The grade has excellent corrosion resistance, for service in sea-water applications and other highly corrosive environments.

The grade is characterized by:

- Excellent resistance to pitting and crevice corrosion

- Excellent resistance to stress corrosion cracking (SCC)

- High resistance to general corrosion in acid and caustic environments

- High resistance to erosion-corrosion

- Very high mechanical strength

- Good weldability using nickel alloy consumables

Standards

- UNS: N08935

- Compliance with NACE MR0175/ISO 15156-3:2015, (Petroleum, Petrochemical, and Natural Gas Industries - Materials for Use in H2S-Containing Environments in Oil and Gas Production - Part 3: Cracking-Resistant CRAs (Corrosion-Resistant Alloys) and Other Alloys) for type 4a and type 4c materials.

- Compliance with ANSI/NACE MR0103/ISO 17495-1:2016, (Petroleum, petrochemical and natural gas industries-Metallic materials resistant to sulfide stress cracking in corrosive petroleum refining environments) for highly alloyed austenitic stainless steels and nickel alloys.

Product standards

- Seamless tube and pipe: ASTM B163, ASTM B677

Approvals

- ASME Code Case 2982-2. Boiler and Pressure Vessel Code, Section VIII, Division I and II.

- Pre-approval for Particular Material Appraisal (PMA), TÜV file 1326W043219

Current maximum temperature:

- 550°C (1022°F) in PED

- 450°C (842°F) in ASME (550°C pending)

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N |

|---|---|---|---|---|---|---|---|---|---|

| ≤0.030 | ≤0.5 | 0.8 | ≤0.030 | ≤0.020 | 27 | 35 | 6.5 | 0.2 | 0.3 |

Applications

Due to its extremely good pitting and crevice corrosion properties, Sanicro® 35 is particularly suitable for applications where seawater is used for cooling or heating. Sanicro® 35 also has a high resistance to general corrosion in acid environments, making it suitable for a variety of applications.

Corrosion resistance

General corrosion

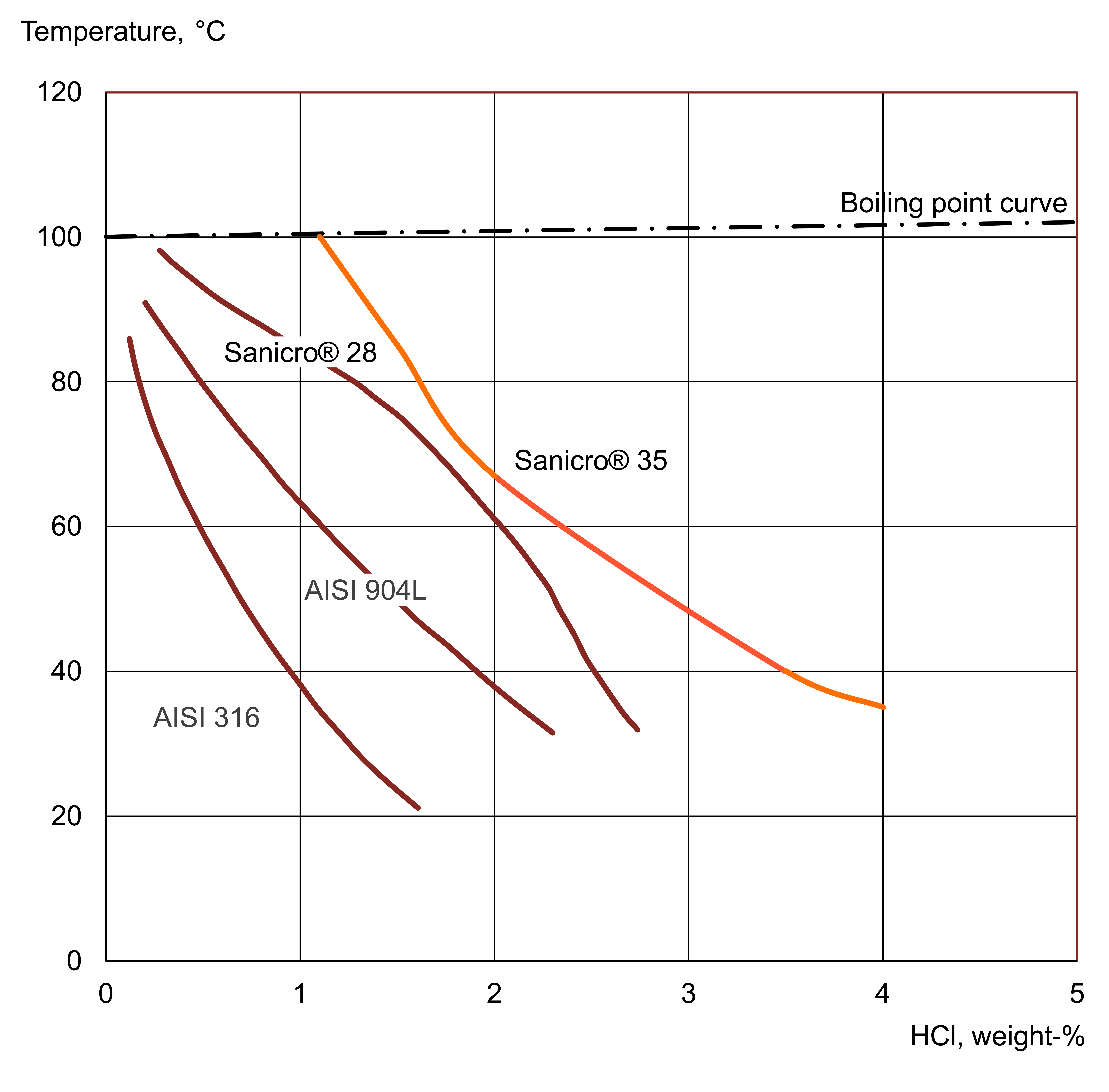

Sanicro® 35 has good resistance to hydrochloric acid compared to stainless steels with a lower chromium and molybdenum content and can, therefore, be useful in environments where hydrochloric acid is present. See Figure 1.

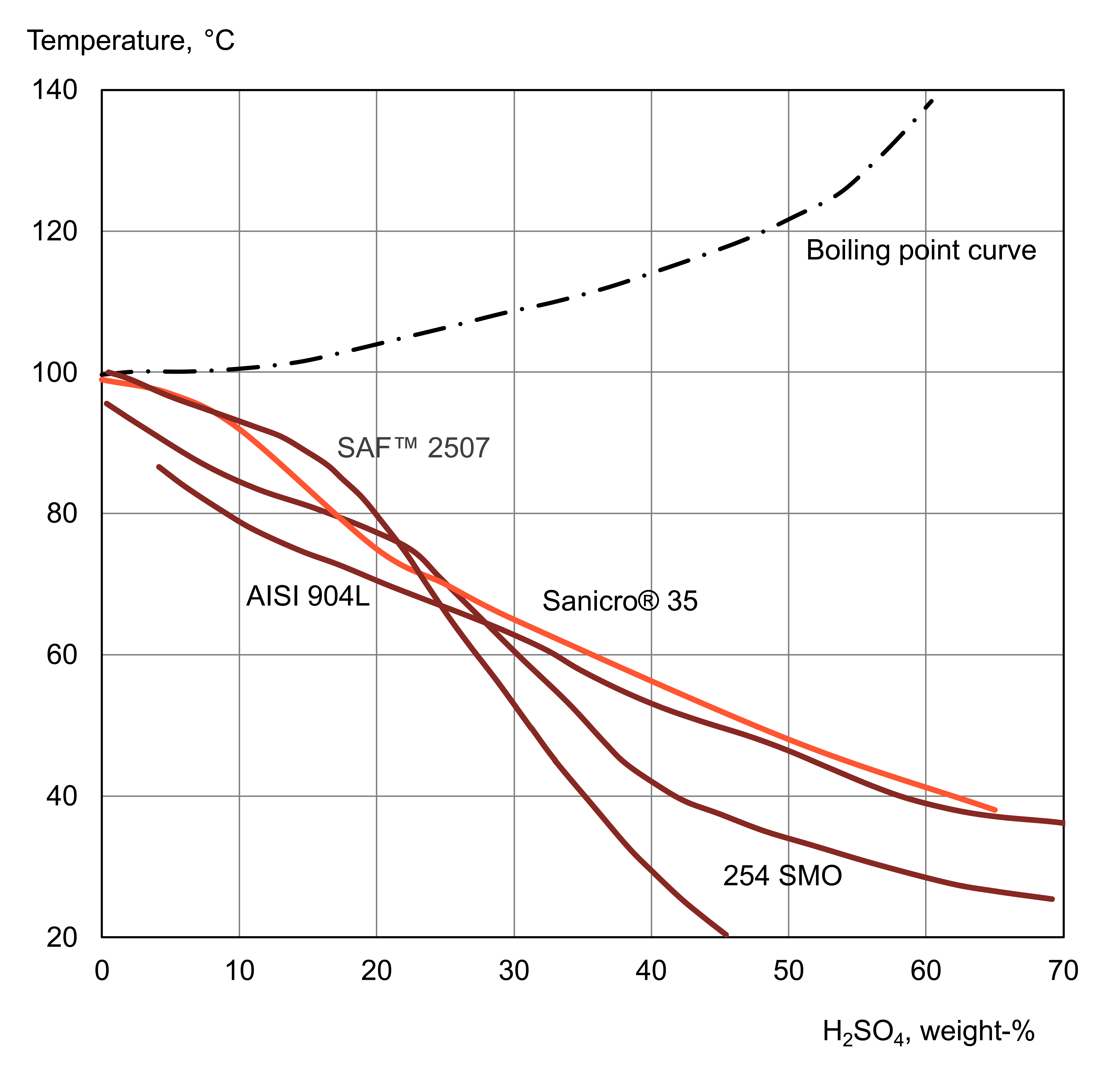

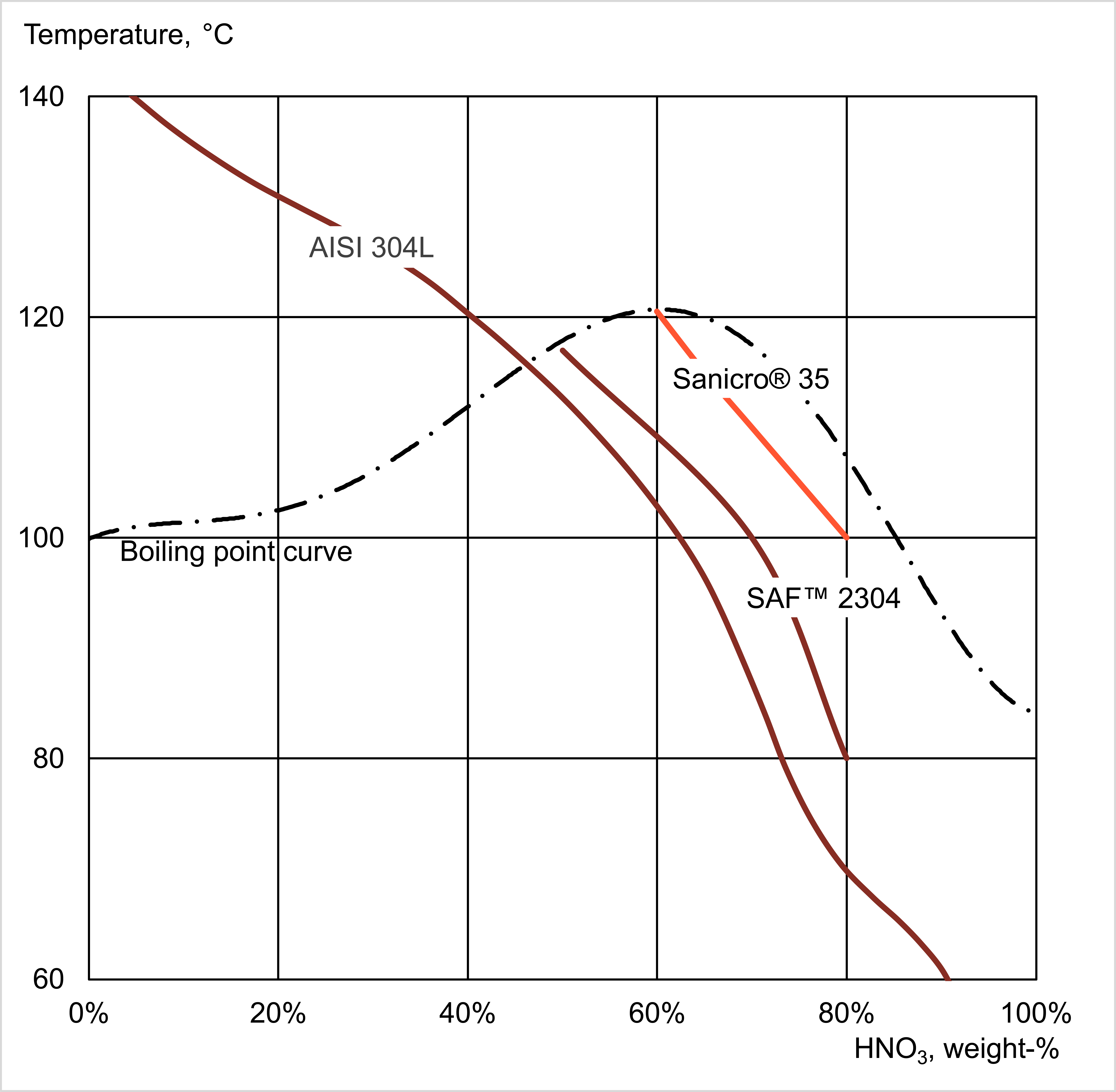

Sanicro® 35 has a high resistance to sulfuric acid and nitric acid. Isocorrosion diagrams can be seen in Figure 2 and Figure 3.

Sanicro® 35 also performs well in mixtures of formic acid and acetic acid, see Table 1.

Table 1. Corrosion rate of Sanicro 35 in mixtures of acetic acid (CH3COOH) and formic acid (HCOOH) at boiling conditions.

| Concentration CH3COOH, % | 50 | 50 | 50 | 50 |

| Concentration HCOOH, % | 10 | 15 | 20 | 25 |

| Corrosion rate, mm/year | 0.00 | 0.00 | 0.00 | 0.01 |

Sanicro® 35 performs well also in alkaline conditions showing high corrosion resistance in caustic solutions, see Table 2.

Table 2. Corrosion rate of Sanicro® 35 in sodium hydroxide (NaOH) at various concentrations and temperatures.

| Concentration NaOH % | 40 | 50 | 60 | 70 |

| Temperature (°C) | 120 | 120 | 120 | 130 |

| Corrosion rate, mm/year | 0.06 | 0.05 | 0.03 | 0.01 |

Pitting corrosion

One of the main advantages of Sanicro® 35 is that it has excellent resistance to pitting corrosion. The pitting resistance comes from the high contents of chromium, molybdenum, and nitrogen. The PREN-number can be used to compare and rank alloys with respect to the chemical composition and possibility to resist pitting. The PREN is defined as, in weight-%;

PREN = %Cr + 3.3 x %Mo +16 x %N

The nominal PREN value for Sanicro® 35 is ~52, comparable to the nickel alloy Sanicro® 625 (Alloy 625). This is significantly higher than e.g. the PREN values for super duplex and 6 Mo austenitic grades which are commonly used in seawater applications. For reference, SAF 2507 and Alleima 254 SMO have a minimum PREN-value of 42.5.

The critical pitting temperature (CPT) has been determined in 6% FeCl3 according to ASTM G48 practice C. The CPT has also been determined in a potentiostatic test in a 3M MgCl2 solution. The test was performed in a modified ASTM G150 test where the solution was changed from 1M NaCl to allow the CPT-measurement of highly alloyed materials. The measured CPT-values can be seen in Table 3.

Table 3. CPT-values for Sanicro® 35 compared to Alleima 254 SMO. The CPT was measured on coupons with P120 surface for the ASTM G48 test and P600 surface for the G150 mod. test.

| Alloy | CPT (°C) | |

| Mod. G150 in 3M MgCl2 | ASTM G48 method C | |

| Sanicro® 35 | 110 | >851)2) |

| Alleima 254 SMO | 67 | 653) |

| Alloy C276 | N/A | >851)2) |

| Alloy 625 | N/A | >851)2) |

1) According to the standard ASTM G48, the method was developed to be used up to 85°C.

2) Method C

3) Method E

Crevice corrosion

Crevice corrosion resistance is equally as important as pitting resistance since crevices can rarely be totally avoided. Sanicro® 35 has excellent crevice corrosion resistance in chloride environments. The critical crevice temperature (CCT) has been determined by potentiostatic tests in 1M NaCl according to standard ASTM G150 and by immersion tests in 6% FeCl3 test solution acidified with HCl according to ASTM G48, see Table 4.

Table 4. CCT-values for Sanicro® 35 compared to some alloys according to various test methods. The applied potential was 700 mV vs. SCE as per ASTM G150. Flat coupons were tested with surfaces wet ground with P600 grit paper for the ASTM G150 test and with P120 for the ASTM G48 tests.

| Alloy | CCT (°C) | ||

| ASTM G1501) | ASTM G48 method D2) |

ASTM G48 method F3) |

|

| Sanicro® 35 | 100 | 52.5 | 45 |

| Alloy C276 | 52.5 | 42.5 | |

| Alloy 625 | 45 | 25 | |

| Alleima 254 SMO | 75 | 35 | |

1) crevice formers according to ISO 18070 with applied momentum of 3 Nm

2) applied momentum of 0.28 Nm

3) applied momentum of 1.58 Nm

Testing in seawater

Accelerated laboratory tests are very good for ranking different alloys, however, real application environment tests are also valuable. Materials are often used in a seawater environment which is very corrosive for many alloys. Sanicro® 35 has been tested for 90 days in natural seawater at 30°C where a biofilm is active and also in 0.5 ppm chlorinated seawater at elevated temperatures.

Table 5. Flat specimens with surfaces ground with P120 grit paper tested in real seawater.

| Test condition | Pitting corrosion | Crevice corrosion1) |

| 30°C natural seawater | No | No |

| 80°C chlorinated seawater (0.5 ppm residual Cl) | No | N/A |

1) crevice formers according to ISO 18070 with applied crevice pressure of 3 N/mm2

Stress corrosion cracking

Ordinary austenitic steels of the ASTM 316 type are susceptible to chloride-induced stress corrosion cracking (SCC) in chloride bearing solutions at temperatures above about 60°C (140°F). This susceptibility declines with increasing nickel content. Chromium contents above 20% can also be beneficial. Sanicro® 35 has excellent resistance to SCC. This is demonstrated in Table 6, which shows the results of SCC tests in a 40% calcium chloride solution. The grade showed no cracking or corrosion after 500 hours of constant load testing, corresponding to 90% of the actual ultimate tensile strength at 100°C. It should be noted that the high loading of 90% of UTS naturally causes plastic deformation of the specimens.

Table 6. Result of stress corrosion cracking test of different alloys in aerated 40% CaCl2, at 100°C (210°F), pH 6.5

| Alloy | % of UTS | Time to failure (h) | Remark |

| Sanicro® 35 | 90 | >500 | No attack |

| Sanicro® 28 | 90 | >500 | No attack |

| ASTM TP 316 | 90 | <70 | Pitting and cracking |

Sanicro® 35 does not suffer from SCC in a NACE MR 0175 / ISO 15156 Test Level VI environment. Slow strain rate testing (SSRT) was performed on cold worked Sanicro® 35 material (140 ksi and 180 ksi), according to NACE TM0198. The environment had partial pressures of 500 psia H2S and 500 psi CO2. 20 wt-% sodium chloride was used as test solution and the temperature was 175°C ± 3°C. For both the 140 ksi and 180 ksi materials, two specimens were tested in the corrosive environment and one in nitrogen. All tests were carried out at the same baseline temperature. Both materials show ductile fractures with ratios of ≥92% for time to failure, elongation to failure, plastic strain to failure and reduction in area compared to inert environment, which indicates no SCC.

Hydrogen embrittlement

Sanicro® 35 shows as expected excellent resistant to hydrogen embrittlement since it has high austenitic phase stability. Sanicro® 35 is not a precipitation-hardened grade which the latter may experience hydrogen embrittlement.

Sanicro® 35 solution annealed material experienced no cracking in constant load testing at 4°C in 3% NaCl at -1050 mVSCE at two different loads present in Table 7. This indicates that the alloy is not prone to hydrogen embrittlement and is a viable option for subsea applications.

Table 7. Sanicro® 35 results from constant load testing at 4°C in 3% NaCl at -1050 mVSCE

| Load/Yield strength, % | Load, MPa | Time to failure, h | Cracking, Yes/No |

| 100 | 427 | >500 | No |

| 120 | 509 | >500 | No |

Fabrication

Bending

The force needed for bending Sanicro® 35 is higher than that for standard austenitic stainless steels which is a natural consequence of the higher yield strength. The excellent formability of the grade permits cold bending to tight bending radii.

Expanding

Sanicro® 35 can be expanded into tube sheets in the same way as standard austenitic stainless steels.

Forms of supply

Sanicro® 35 can be supplied as seamless tube and pipe.

Heat treatment

Tubes are delivered in solution annealed condition. If additional heat treatment is needed after further processing, please contact Alleima.

Mechanical properties

The following figures apply to material in the solution annealed condition.

At 20°C (68°F)

Metric units

| Proof strength | Tensile Strength | Elongation | |

| Rp0.2a | Rm | A2” | |

| MPa | MPa | % | |

| Tube, ASTM B163 | ≥425 | ≥750 | ≥35 |

| Pipe, ASTM B677 | ≥400 | ≥750 | ≥35 |

Imperial units

| Proof strength | Tensile Strength | Elongation | |

| Rp0.2a | Rm | A2” | |

| ksi | ksi | % | |

| Tube, ASTM B163 | ≥62 | ≥109 | ≥35 |

| Pipe, ASTM B677 | ≥58 | ≥109 | ≥35 |

1 MPa = 1 N/mm2

a) Rp0.2 and Rp1.0 corresponds to 0.2% and 1.0% offset yield strength.

b) Based on L0 = 5.65 √S0 where L0 is the original gauge length and S0 the original cross-section area.

At high temperatures

Intermetallic phases are precipitated at temperatures above 600°C (1110°F). Therefore, the steel should not be exposed to these temperatures for prolonged periods.

Metric units

| Temperature | Proof strength | Proof strength | Tensile strength | Elongation |

| Rp0.2 | Rp0.2 | Rm | A | |

| °C | MPa | MPa | MPa | % |

| Tube, ASTM B163 | Pipe, ASTM B677 | |||

| Min. | Min. | Min. | Min. | |

| 100 | 350 | 325 | 680 | 35 |

| 200 | 300 | 285 | 620 | 35 |

| 300 | 275 | 260 | 600 | 35 |

| 400 | 250 | 240 | 580 | 35 |

Imperial units

| Temperature | Proof strength | Proof strength | Tensile strength | Elongation |

| Rp0.2 | Rp0.2 | Rm | A | |

| °F | ksi | ksi | ksi | % |

| Tube, ASTM B163 | Pipe, ASTM B677 | |||

| Min. | Min. | Min. | Min. | |

| 200 | 51 | 48 | 98 | 35 |

| 400 | 43 | 41 | 90 | 35 |

| 600 | 39 | 37 | 87 | 35 |

| 800 | 36 | 34 | 84 | 35 |

Physical properties

Density: 8.1 g/cm3, 0.29 lb/in3

Thermal conductivity

| Temperature, °C | W/(m °C) | Temperature, °F | Btu/(ft h °F) |

| 20 | 10.0 | 68 | 6.0 |

| 100 | 12.0 | 200 | 7.0 |

| 200 | 13.5 | 400 | 8.0 |

| 300 | 15.5 | 600 | 9.0 |

| 400 | 17.0 | 800 | 10.0 |

Specific heat capacity

| Temperature, °C | J/(kg °C) | Temperature, °F | Btu/(lb °F) |

| 20 | 450 | 68 | 0.11 |

| 100 | 470 | 200 | 0.11 |

| 200 | 500 | 400 | 0.12 |

| 300 | 510 | 600 | 0.12 |

| 400 | 530 | 800 | 0.13 |

Thermal expansion

Metric units, x10-6/°C

| Temperature, °C | 30-100 | 30-200 | 30-300 | 30-400 |

| Sanicro® 35 | 14.0 | 14.5 | 15.0 | 15.5 |

| Carbon steel | 12.5 | 13.0 | 13.5 | 14.0 |

| ASTM 316L | 16.5 | 17.0 | 17.5 | 18.0 |

Imperial units, x10-6/°F

| Temperature, °C | 86-200 | 86-400 | 86-600 | 86-800 |

| Sanicro® 35 | 8.0 | 8.0 | 8.5 | 8.5 |

| Carbon steel | 7.0 | 7.0 | 7.5 | 8.0 |

| ASTM 316L | 9.5 | 9.5 | 10.0 | 10.0 |

Resistivity

| Temperature, °C | μΩm | Temperature, °F | μΩinch |

| 20 | 1.0 | 68 | 39 |

Modulus of elasticity, x103

| Temperature, °C | MPa | Temperature, °F | ksi |

| 20 | 190 | 68 | 28.0 |

| 100 | 185 | 200 | 27.0 |

| 200 | 180 | 400 | 26.0 |

| 300 | 175 | 600 | 25.0 |

| 400 | 170 | 800 | 24.5 |

Welding

The weldability of Sanicro® 35 is good and a suitable method for fusion welding is TIG welding (GTAW).

Welding should be undertaken with low heat input, maximum 1.2 kJ/mm, and interpass temperature 100 °C maximum. A stringer welding technique should be used. Preheating and post-weld heat treatment are not necessary. To maintain full corrosion resistance of the welded joint, welding must be followed by thorough cleaning to ensure the removal of all oxides and heat tint. Ar is recommended as shielding gas and backing gas with TIG welding to achieve the best combination of mechanical properties and corrosion resistance of the welded joints.

Welding of fully austenitic stainless steels and nickel-base alloys often involves the risk of hot cracking in the welded joints if the weldment is under constrain. Sanicro® 35, however, possesses very high purity, and is thereby less prone to hot cracking than most of the nickel-base alloys.

Nickel alloy UNS N06059 (ERNiCrMo-13, NiCr23Mo16) wire or rod is recommended as filler material for gas shielded arc welding. Welding without filler material is not recommended.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.