Recuperator tubes in a wide range of high-temperature corrosion resistant materials suitable for flue gas temperatures up to 1300ºC (2370ºF).

The Alleima portfolio covers materials for most types of recuperators used for heat recovery in, for example, steel and metal processing, glass production and carbon black production.

Materials for increased heat efficiency

The Alleima portfolio includes several materials allowing for higher operating temperature, enabling increased heat recovery and higher efficiency. Examples are Kanthal APMT and Alleima® 253 MA*.

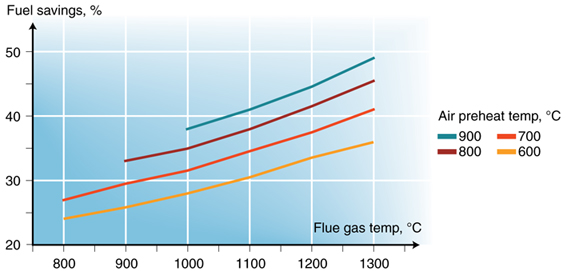

Savings in fuel consumption at different waste gas and air preheat temperatures

Recuperator tube materials (other grades can be offered on request)

| Alleima grade (UNS) | Description |

|---|---|

| Alleima® 253 MA* (UNS S30815) |

Austenitic stainless steel alloyed with nitrogen and REM (rare earth metals). Suitable for most types of conditions. |

| Alleima® 353 MA* (UNS S35315) |

Austenitic stainless steel alloyed with nitrogen and REM (rare earth metals). Suitable for oxidizing, carburizing and nitriding conditions. |

| Alleima® 4C54 (UNS S44600) |

Ferritic stainless steel with a high chromium content (26.5%) suitable for sulphudizing conditions. |

| Sanicro® 31HT (UNS N08811/N08810) |

Austenitic stainless steel with good resistance to oxidation. Suitable for oxidizing, nitriding and carburizing conditions. |

| Kanthal APM & Kanthal APMT |

Ferritic iron-chromium-aluminium (FeCrAl) stainless steel with superior oxidation properties. Suitable for sulphudizing conditions in the highest temperatures. |

*253 MA and 353 MA are trademarks owned by Outokumpu OY