How can we help you achieve better chip breaking?

Machining stainless and duplex stainless steels is a challenge due to the high strength of the material, and chip-breaking is closely related to the microstructure. In our hot working process, we ensure that the material has an even and optimized microstructure throughout the entire length of the bar.

Chip formation is one of the most crucial aspects of any machining activity. Poorly managed chip breaking can harm the workpiece, the cutting tool and even be a major hazard for the operator. So why is chip breaking difficult when machining austenitic and duplex stainless steels, compared to other materials?

Toughness and ductility

Both austenitic and duplex stainless steels are known to have high toughness and ductility, and this is mainly due to the high elasticity of the austenitic phase structure (FCC) of the material. High ductility often leads to poor chip breaking, with long, continuous chips that can wrap around the work-piece or tool.

Low thermal conductivity

Compared to carbon steels, stainless steels have approximately a third of the thermal conductivity properties. Considerably less heat leaves the cutting process together with the chip and more heat is transferred into the insert, necessitating a lower cutting speed for stainless steel materials, compared to carbon steels. Low thermal conductivity also leads to built-up edges, where material smears onto the insert. This then rips away the coating of the insert, deteriorating the insert edge.

High proof strength

Austenitic stainless steels and normal carbon steels for machining are quite comparable in material strength. But duplex stainless steels are about twice as strong as regular austenitic or ferritic stainless steels. Machining duplex produces strong and hard chips, which can cause chip-hammering at the insert and create high cutting forces. The high proof strength also limits both the feed rate in the material and the cutting speed.

How can we help you achieve better chip breaking?

Our materials know-how

Chip-breaking is always a challenge when machining stainless - and especially duplex stainless steels - due to the high strength of the material. This is where our material know-how comes to the forefront. We know that many stoppages in the machine are related to chip breaking. Either the chip has stuck to the tool, the work-piece, or in the conveyor. Stoppages like these are often quite hazardous for the operator and can take time to solve. Time that could be spent running the next part, or perhaps maintaining a second machine? Having the chip breaking under control means a reduction of unwanted stoppages and more output from the machining process.

Energy consumption

Chip-breaking, but also energy consumption, is closely related to the microstructure. In our hot working process, we ensure that the material has an even and optimized microstructure throughout the entire length of the bar. We use non-metallic inclusions to manipulate the microstructure, so that when the material is heated up in the cutting zone, it will yield at a lower mechanical load, allowing the chip to break off easily. This will give very predictable machining, with the lowest possible energy consumption. An uneven material microstructure would directly affect chip breaking, tool-life, and result in uneven quality of the component. Sanmac® materials have been designed and developed to give better chip breaking properties compared to similar products available on the market.

General information about chip formation

The chip formation process implies that a fresh metal interface is continually produced between the tool material and the workpiece at varying cutting forces, angles and temperatures. When a cutting edge performs its metal cutting function properly, it deforms part of the workpiece material plastically, then ejects it.

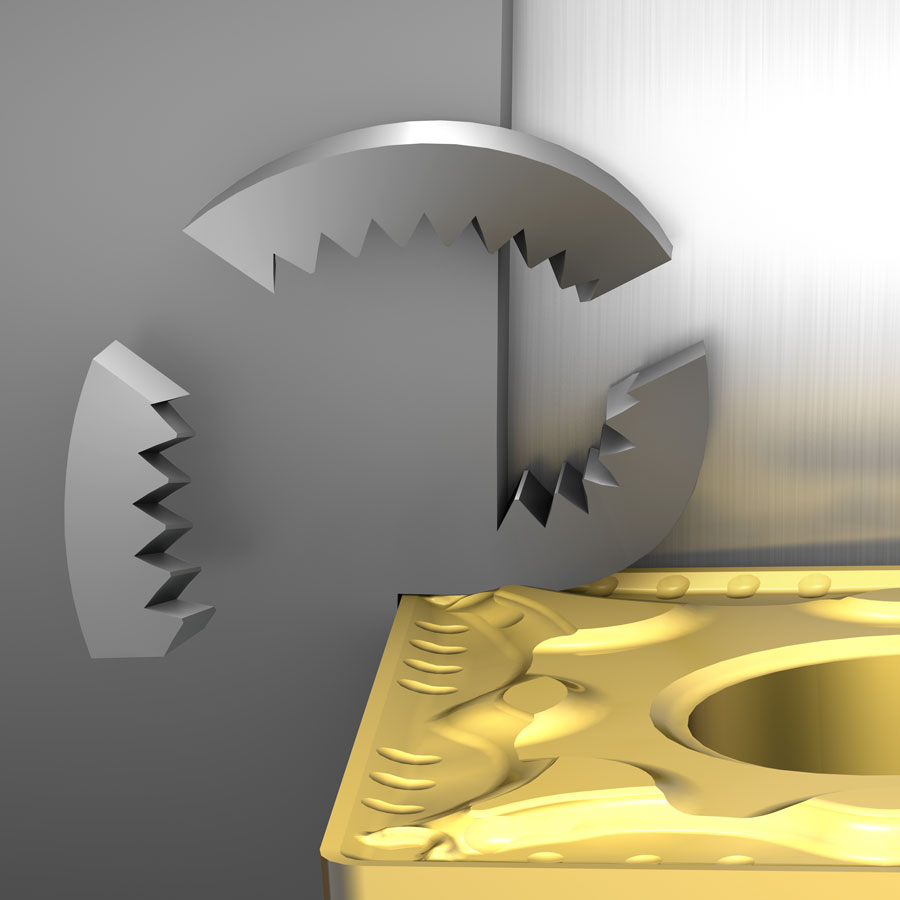

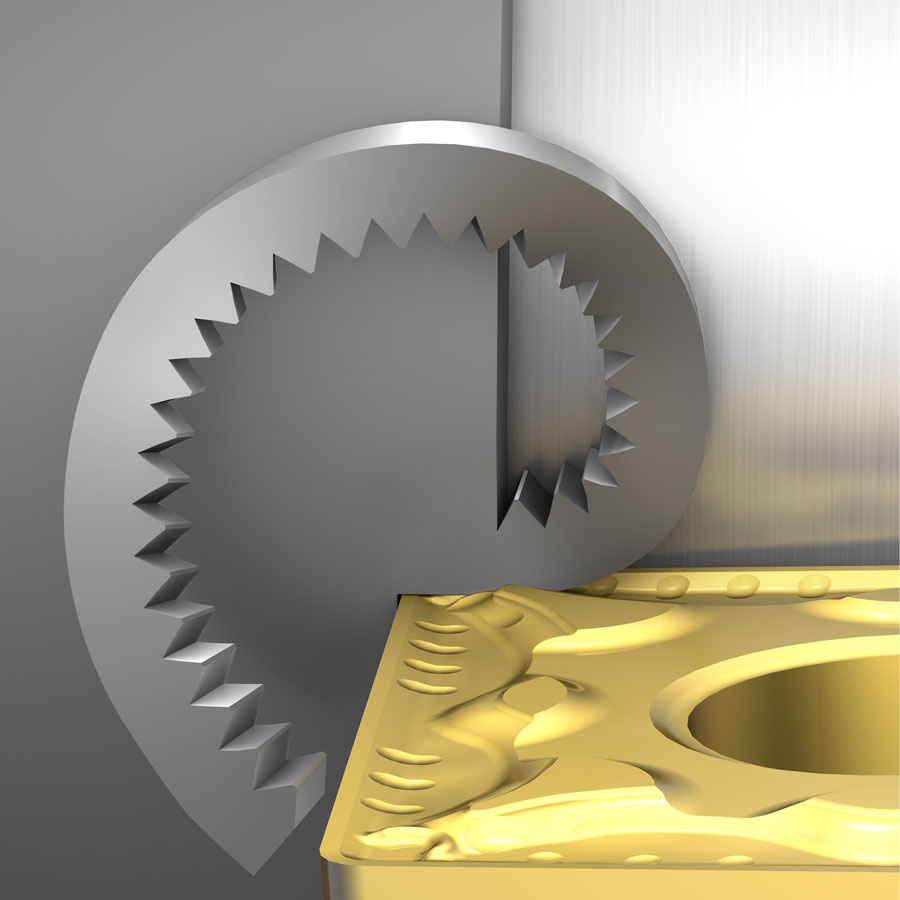

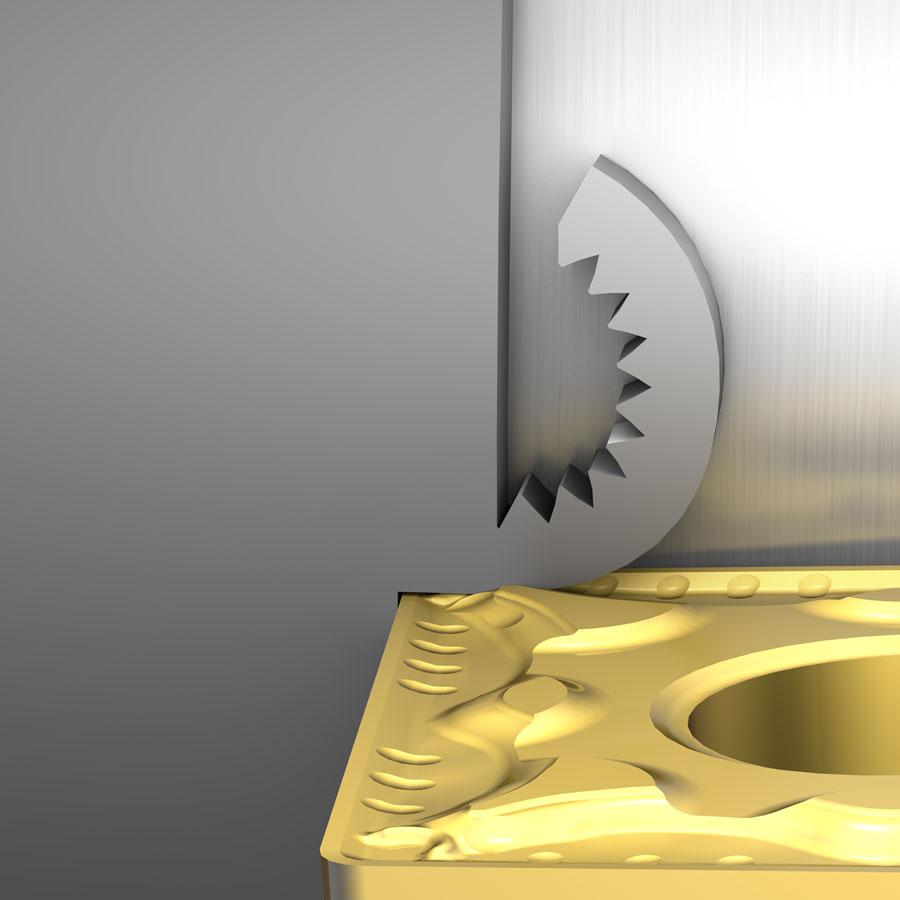

Chips normally break off in one of three ways:

Self-breaking: chips that are an ideal size pose no threat to the machine and will not damage the part, tool holder or insert

Self-breaking: chips that are an ideal size pose no threat to the machine and will not damage the part, tool holder or insert

Breaking against the tool: chips that break against the tool can cause chip hammering and tool breakage

Breaking against the tool: chips that break against the tool can cause chip hammering and tool breakage

Breaking against the workpiece: chips that break against the workpiece can damage the surface finish

Breaking against the workpiece: chips that break against the workpiece can damage the surface finish

Factors influencing chip breaking

Materials

A short-chipping material like cast iron is generally easier to machine. For stainless and duplex materials with high mechanical strength and resistance to creep, chip breaking is more difficult.

Insert geometry

Based on width of chip room and design of micro- and macro-geometry, the chip will be open or more compressed. An open insert geometry generates less heat but gives decreased chip breaking at moderate feed-rates. A tight chip room increases the chip-breaking but generates more heat from the increased friction.

Nose radius

A smaller nose radius controls the chip more than a bigger nose radius but is more sensitive to heat and high mechanical loads.

Entry angle

Depending on angle, the chip is directed in different ways; towards the material or out from the material. A low entry angle is more desirable when machining notch inflictive materials such as stainless steels and especially duplex materials. The downside is that a low entry angle also leads to less good chip formation.

Cutting depth

Depending on the workpiece material, a larger cutting depth will influence chip breaking, with greater forces needed to break and remove the chip. In stainless and duplex materials, a cutting depth of three millimeters is quite common for medium applications.

Feed

Higher feed will, in general, create stronger chips and can in some cases help chip breaking and chip control. But a higher feed-rate will also generate higher cutting forces, and demand both a strong and rigid machine and tooling.

Cutting speed

A change of cutting speed can influence the chip breaking performance, both to increase the temperature - reducing built-up edge but also to change the chip direction - due to a change in the contact point between the insert and the chip.

The impact of poor chip breaking

Operator safety

The person that is most affected by poor chip breaking is the machine operator. It is he or she that must remove the long and stringy chips around the work-piece or tool-holder and in the chip conveyor. Having to do this may be considered normal when machining austenitic and duplex stainless materials, but at Alleima, we do not agree. By using Sanmac® materials, in combination with our tooling and machining know-how, poor chip breaking can be minimized. This will not only lead to a better work environment for the operator but also reduce the down-time in the machine for removing stringy chips.

Productivity

Problems with chip control in the machining process require many adjustments to be made to cope with the situation. Lowering the machining parameters to a safe zone is the normal route to take and using more secure but less productive inserts in the metal cutting process. This all affects the overall productivity and the throughput of material.

Secure production

Poor chip breaking means that the operator must always monitor the machine. Apart from chips becoming entangled in the work-piece and/or the tool, this will also affect the insert tool-life, mainly related to mechanical damage on the insert edge when re-cutting the stringy chips stuck to the work-piece. This kind of damage can appear sporadically and may cause insert breakage which will affect the surface of the component. Worst case, the component may need to be scrapped and the machining process repeated from scratch. When control over chip breaking is achieved, the operator can attend to other work, like preparing the next job or maintaining a second machine. Security and predictability in the machining process is a prerequisite to further optimize the machine and tooling parameters.

Loss of yield and profit

For the reasons mentioned above, poor chip-breaking affects the potential output from the machining process by as much as 20%. This will negatively impact the production cost per component, and ultimately the gross profit. A productivity increase of 20% will, in a normal production system, give a gross profit impact of almost 100% for the whole system.

This can make the difference between having the means to invest in new machinery, adding another shift to produce more parts, or not.