SAF™ 2707 HD is a hyper-duplex stainless steel; a high-alloy duplex steel with a PRE value of min. 48*. The grade is characterized by excellent chloride corrosion resistance, combined with very high mechanical strength.

SAF™ 2707 HD is particularly suited for use in aggressive environments such as hot chlorinated seawater and for highly acidic, chloride containing media. SAF™ 2707 HD has better resistance to pitting and crevice corrosion and higher mechanical strength than all super-duplex stainless steel grades available on the market.

An alternative to nickel alloys

SAF™ 2707 HD hyper-duplex stainless steel is a very competitive alternative to expensive nickel alloys and high-alloy austenitic stainless steels in the most demanding applications, such as tropical seawater and severe corrosive environments in chemical and petrochemical processing.

The excellent performance of SAF™ 2707 HD is helping to increase service life and reducing maintenance in many types of heat exchangers. The grade also contributes to better reliability by minimizing the risks of leakage and contamination.

Main characteristics of SAF™ 2707 HD

- Excellent resistance to pitting and crevice corrosion

- Excellent resistance to stress corrosion cracking (SCC) in chloride containing environments

- High resistance to general corrosion in acidic environments

- Excellent resistance to erosion corrosion

- Excellent corrosion fatigue properties

- Extremely high mechanical strength

- Physical properties that offer design advantages

- Good weldability

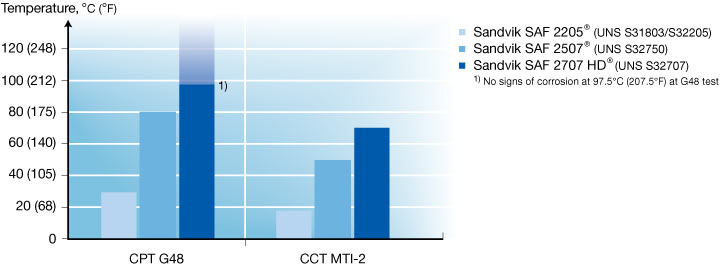

The below graph shows the critical pitting temperature (CPT) and critical crevice corrosion temperature (CCT) in 6% FeCl3 testing.

* PRE stands for pitting resistance equivalent and is defined as, in weight-%:

% Cr + 3.3 x % Mo + 16 x % N

The PRE value mentioned above is valid for tube and pipe.