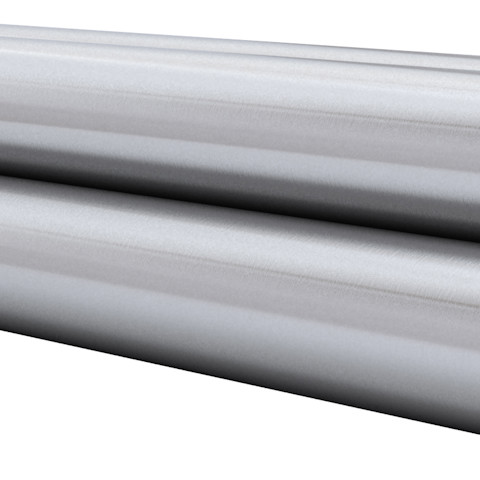

Evaporator tubes in a wide range of stainless steels. Our range of tubes for evaporators includes grades that are suitable for environments with high chloride contents, extreme pH values and for media with risk for crevice corrosion caused by deposits.

| Material | Description |

|---|---|

| SAF™ 2707 HD | A hyper-duplex stainless steel with excellent resistance to crevice corrosion in chloride containing media. The grade is a very competitive alternative to expensive nickel alloys. |

| SAF™ 2507 | A super-duplex stainless steel with very good corrosion resistance in seawater and other chloride containing media. |

| SAF™ 2906* | A super-duplex stainless steel suitable for use in sodium hydroxide (NaOH). |

| Sanicro® 28 | A high-alloy austenitic stainless steel with very good corrosion properties. The grade is particularly suited for use in phosphoric acid production. |

* Contact us for more information