Alleima® Ti Grade 12 is a titanium grade alloyed with molybdenum and nickel. It is characterized by excellent corrosion resistance in reducing and oxidizing environments and offers better heat resistance than pure titanium grades. Alleima Ti Grade 12 is suitable for applications such as shell and tube heat exchangers and is typically used within, for example, the chemical industries.

Standards

- ASTM: Grade 12

- UNS: R53400

Chemical composition (nominal)

| Fe | O | C | H | N | Mo | Ni |

|---|---|---|---|---|---|---|

| ≤0.30 | ≤0.18 | ≤0.08 | ≤0.015 | ≤0.03 | 0.2 - 0.4 | 0.6 - 0.9 |

Ti=Bil

Fabrication

Bending

Titanium tubing can be bent at room temperature using standard bend tooling and techniques. When bending thin walled tubing or if a tight bend radius is needed, a mandrel should be used for adequate support of the ID. The mandrel should be well lubricated in order to prevent galling of the ID surface. Due to the moderate strength and low modulus of this alloy, springback is about twice that of stainless steel and must be taken into account.

Roller expansion

Titanium tubing can be roller expanded into tube sheets similar to other tubing materials. The suggested wall reduction for titanium is 10% to provide optimum pull out strength.

Machining and cutting

Machining and cutting titanium tubing is routine when the following procedures are used:

- Use low cutting speeds and high feed rates

- Use large volumes of coolant

- Use sharp tools and replace as soon as worn

- Never stop feeding while tool is in contact with workpiece

Tubing and pipe specifications

ASTM B337: Seamless and welded pipe

ASTM B338: Seamless and welded tubing

ASME SB338: Seamless and welded tubing

Sizes and surface conditions

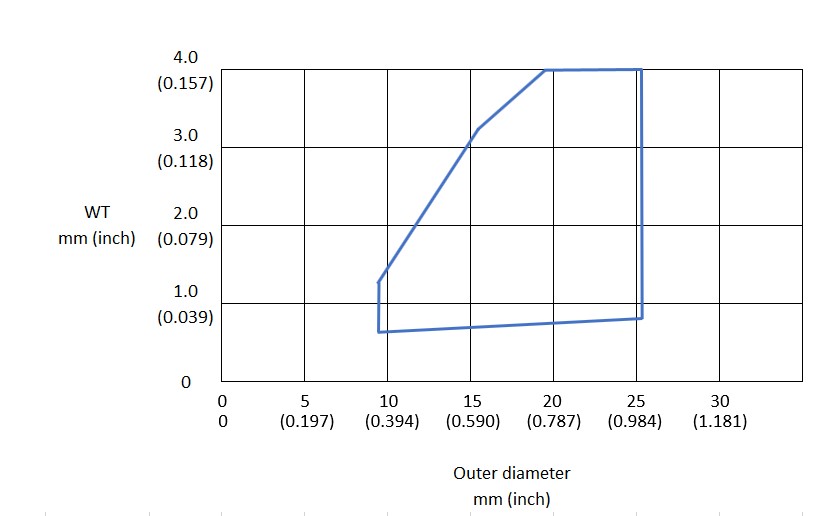

Tube and pipe are supplied in the cold reduced or cold reduced and annealed condition. Tubing can be delivered in the following surface conditions: as cold pilgered, acid etched, or belt polished. The principal size range for seamless products is shown as the white area in figure 1.

Figure 1 Principal size range for seamless tube and pipe.

| OD | WT | L |

| 9.50 - 24.4 mm | .07 - 4 mm | up to 17 m |

Other dimensions can be quoted for special projects.

Mechanical properties

Tensile properties for Grade 12 titanium shown below:

| Ultimate Strength | Yield strength | Elongation 2" | |||

| ksi | MPa | ksi | MPa | ||

| Min | 70 | 483 | 50 | 345 | 18 |

| Max | - | - | - | - | - |

| Typical data | 573 | 421 | 36 | ||

Physical properties

Density 0.162 lbs/in3, 4.51 g/cm3

Melting point

3020°F, 1660°C

Beta transus

1634F, 890°C

Thermal Conductivity

| Temperature, °C | 23 | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 |

| Thermal conductivity, W/mK | 18,1 | 17,5 | 17,0 | 16,6 | 16,3 | 16,1 | 16,1 | 16,2 | 16,3 | 16,4 | 16,5 | 16,7 | 17,1 | 17,7 | 18,3 |

Elastic modulus

The elastic modulus of Cp titanium, as shown below, is roughly one-half that of steel alloys.

| psi | GPa | |

| Tension (E) | 15.0 x 106 | 103 |

Weldability

The weldability of CP titanium tubing is very good as long as the necessary precautions are taken. Due to the reactive nature of titanium inert gas shielding must be in place on both the OD and ID of the tubes. The material must be also

free from any grease or oil contamination.

Manual or automatic TIG welding is regularly used to weld titanium tubing either with or without filler wire. A low heat input should be used to minimize the size of the heat-affected zone. No post-weld heat treatment is normally performed on

titanium tubing.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.