Hiflex™ is a hardened and tempered martensitic stainless compressor valve steel alloyed with molybdenum. The material is characterized by:

- High strength and good ductility

- Extremely high fatigue strength under bending and impact stress

- Excellent surface finish

- Very high compressive residual surface stress

- Low level of non-metallic inclusions

- Good wear resistance

Hiflex™ compressor valve steel has good dimensional tolerances and good flatness.

Standards

- UNS: S42026

- EN Number: (1.4031)*

*) Nearest equivalent grade

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.38 | 0.40 | 0.55 | ≤0.025 | ≤0.010 | 13.5 | 1.0 |

Applications

Valve production

Valves made from Hiflex™ compressor valve steel should be produced with fatigue properties in mind, in order to make full use of the excellent material properties.

Valve types:

- Flapper valves

- Reed valves

- Check valves

Corrosion resistance

Hiflex™ is a martensitic chromium steel alloyed with molybdenum, giving better corrosion resistance and higher corrosion fatigue strength than conventional steels of the ASTM 420 type.

Fabrication

Blanking

It is recommended that blanking is made in a straight-side press using blanking tools with sharp edges. Worn or damaged tools can cause edge defects on the valve that can be difficult to remove in later processes. A punch to die clearance of 4-10% of the strip thickness is recommended.

Tool steels ASTM D2 or D4 are recommended except for thick strip gauge, slender tool sections or small corner radii. In this case ASTM M2 steels are recommended. In both cases the tool hardness should be about 63 HRC.

Stress relieving

Stress relieving may be performed between blanking and tumbling operations in order to remove blanking stresses. A maximum temperature of 350ºC (662ºF) for 30-60 minutes is recommended.

Tumbling

A good tumbling operation giving a round, smooth edge is necessary in order to minimize stress concentrations. Tumbling also increases the residual compressive surface stresses which gives a significant further improvement in fatigue properties.

Forms of supply

Conditions and forms of supply

Strip steel is supplied in labelled coils, or on labelled plastic spools, depending on weight and size. The label details the steel grade, heat, lot and coil number, and nominal size, allowing full material traceability. Material is protected against rust with oil.

Coils are wrapped in paper and packed in wooden cases. For overseas shipment, coils are also sealed in a plastic bag containing silica gel. Net and gross weights are marked on the case. Customised properties, dimensions and tolerances can be supplied on request.

Dimensions

Thickness

Hiflex™ is supplied in standard thicknesses in accordance with the table. Customized thicknesses can be supplied on request.

| Thickness | Tolerances | ||

|---|---|---|---|

| mm | in. | mm | in. |

| 0.152 | 0.006 | 0.005 | 0.00020 |

| 0.203 | 0.008 | 0.006 | 0.00024 |

| 0.254 | 0.010 | 0.007 | 0.00028 |

| 0.305 | 0.012 | 0.007 | 0.00028 |

| 0.381 | 0.015 | 0.008 | 0.00035 |

| 0.406 | 0.016 | 0.012 | 0.00047 |

| 0.457 | 0.018 | 0.012 | 0.00047 |

| 0.508 | 0.020 | 0.014 | 0.00055 |

| 0.600 | 0.0236 | 0.020 | 0.00079 |

Width

Strip in standard thicknesses is stocked in widths up to 310 mm (12.2 in.), ready for slitting to the required width.

Finish

Edges

Edges are slit and deburred. Shaved edges can be supplied on request.

Flatness

Maximum out-of-flatness across and along the strip is 0.20% of the nominal strip width.

Surfaces

Maximum surface roughness values, cut-off 0.25 mm (0.0098 in.), are shown in the table.

| Thickness | Ra | Rmax | |||

|---|---|---|---|---|---|

| mm | in. | µm | µin. | µm | µin. |

| ≤0.508 | ≤0.020 | 0.13 | 5.2 | 1.5 | 60 |

| >0.508 | >0.020 | 0.25 | 10.0 | 2.5 | 100 |

Surface defects

A small number of surface defects, such as pits and roll marks, with a depth or height of 2 µm (80 µin.) maximum is allowed for thicknesses up to 0.508 mm (0.020 inch) and 3 µm (120 µin.) maximum for thicker material. The maximum scratch depth allowed is as follows:

| Thickness | Max. allowed depth | ||

|---|---|---|---|

| mm | in. | µm | µin. |

| ≤0.203 | ≤0.008 | 0.5 | 20 |

| >0.203-≤0.508 | >0.008-≤0.020 | 0.8 | 32 |

| >0.508 | >0.020 | 1.0 | 40 |

Straightness

Out-of-straightness is defined as the maximum deviation from a straight-edge of a specified length. The following values apply:

| Strip width | Max. allowed deviation | ||

|---|---|---|---|

| mm | in. | mm/m | in./3 feet |

| ≥-<20 | ≥0.315-<0.787 | 2.0 | 0.072 |

| ≥20-<50 | ≥0.787-<1.969 | 1.5 | 0.054 |

| ≥50-<125 | ≥1.969-<4.921 | 1.25 | 0.045 |

| ≥125 | ≥4.921 | 1.0 | 0.036 |

Mechanical properties

| Proof strength | Tensile strength | Elongation | ||||

|---|---|---|---|---|---|---|

| Rp0.05 | Rp0.2 | Rm | ||||

| MPa | ksi | MPa | ksi | MPa | ksi | % |

| nominal | nominal | nominal | ||||

| 1300 | 189 | 1500 | 218 | 1900 | 276 | ≥6 |

The values are valid for thicknesses up to 0.60 mm (0.024 inch). The manufacturing tolerance for tensile strength is ±60 MPa (±8.7 ksi).

Fatigue strength

Hiflex™ compressor valve steel has a high response to surface treatment, such as tumbling and shot peening, which gives a significant increase in fatigue life.

Reversed bending fatigue (mean stress = 0)

The fatigue strength of Hiflex™ flapper valve steel in reversed bending is ±750 MPa (±109 ksi) at a failure rate of 5%.

Fluctuating bending fatigue (minimum stress = 0)

Fluctuating bending fatigue strength for Hiflex™ compressor valve steel has been calculated from reversed bending values at a 5% failure rate. Goodmans formula gives 538±538 MPa (ksi). Gerbers formula gives 660±660 MPa. The value is valid for a strip thickness of 0.381 mm (0.015 in.).

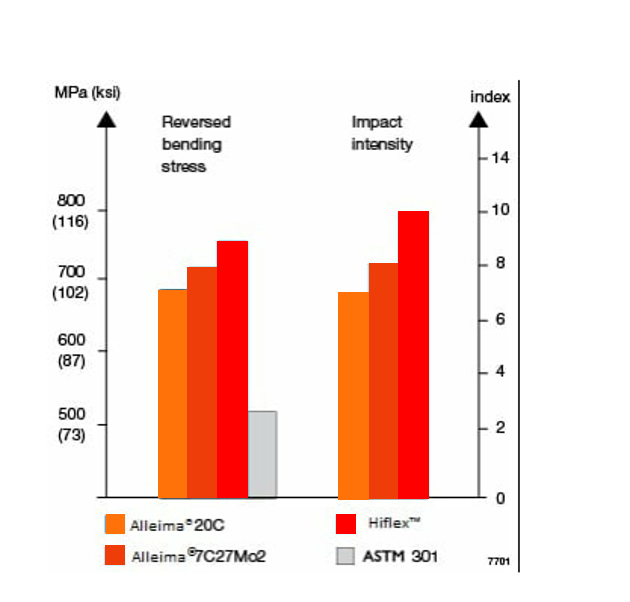

Comparison with other steel grades

Physical properties

Density, 7.7 g/cm3, 0.27 lb/in3

| At 20°C, W/(m °C) | 24 |

|---|---|

| At 68°F, Btu/(ft h °F) | 14 |

| Mean value for 50-100°C, J/(kg °C) | 460 |

|---|---|

| Mean value for 120-210°F, Btu/(lb °F) | 0.11 |

| Temperature | Temperature | ||

|---|---|---|---|

| °C | per °C (x 10-6) | °F | per °F (x 10-6) |

| 30-100 | 10.5 | 86-200 | 6 |

| 30-200 | 11 | 86-400 | 6 |

| 30-300 | 11.5 | 86-600 | 6.5 |

| MPa | 210000 |

|---|---|

| ksi | 30500 |

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.