Stainless steel or titanium?

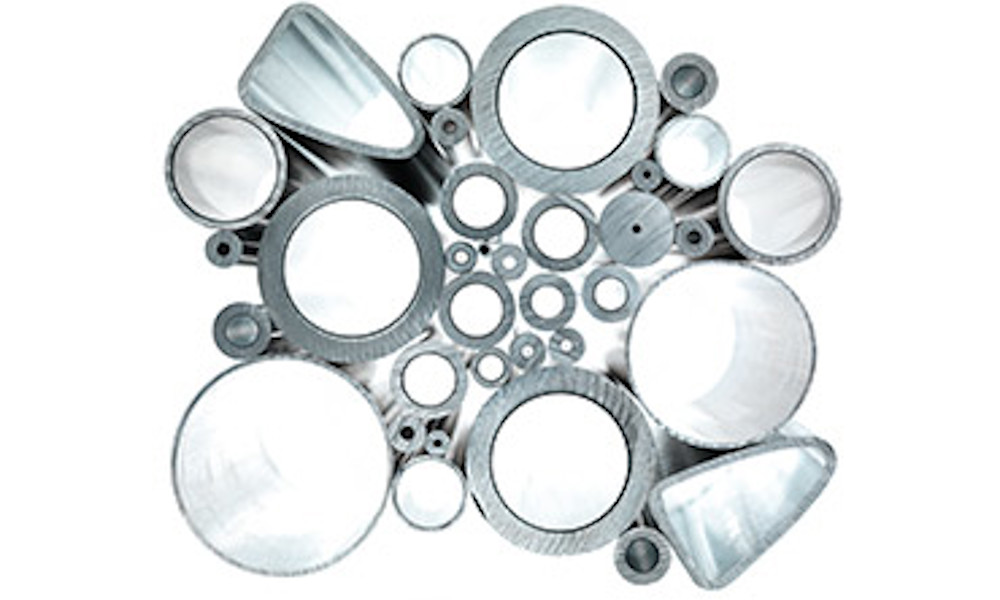

Alleima advanced stainless steel and titanium alloys are already being used in the pipes and tubes that make up aircraft hydraulic systems. Whereas titanium provides the lightness that is so key to increased fuel efficiency, some parts are better suited to stainless steel due to pressure requirements.

“The ability to cope with higher pressures and temperatures allows engines to run more efficiently,” he continues, adding that this is will be a key focal area for Alleima going forward.

“Engine producers are constantly promising airlines more efficient engines. To deliver that, they need more and more complicated material,” he continues.

Looking to the long-term, beyond improving the efficiency of existing solutions, many commentators believe a paradigm shift is on the horizon, as the industry prepares for the arrival of hydrogen-powered aircraft.

Hydrogen emerging as the fuel of the future

“Like elsewhere in society, hydrogen is fast emerging as the most interesting alternative fuel source,” says Hedvall.

Hydrogen has the potential to significantly reduce CO2 emissions, opening the door to the possibility of sustainable long-distance transportation, on land, in the water and in the air.

Earlier this year, Airbus signed a Memorandum of Understanding (MoU) with Linde, a leading global industrial gases and engineering company. Going forward, the two will work together to develop hydrogen infrastructure at airports worldwide.

"We are advancing well with hydrogen as an important technology pathway to achieve our ambition of bringing a zero-emission commercial aircraft to market by 2035. Building the infrastructure is just as crucial. That's why we are working closely with partners like Linde, who have decades of experience and expertise worldwide in the storage and distribution of hydrogen," said Sabine Klauke, Chief Technical Officer, Airbus.

The volume conundrum

Needless to say, developing the necessary technology to produce, transport and store the huge volumes of hydrogen that would be required to fuel the aviation industry of the future represents no small feat. Even more so considering that the volume of hydrogen is four times as much as the one of kerosene.

This has prompted widespread concerns about how the hydrogen will be delivered to airports, whether this will require the use of pipelines or liquid hydrogen tankers, how it will be securely transported on board aircraft and whether hydrogen-powered aircraft can be safely serviced and refueled alongside conventional aircraft.

However, as Guirec Guyon is quick to point out, hydrogen as a fuel source is not some new-fangled invention. Although new applications will be needed to make it usable at the scale the commercial aviation industry would require, it has already been successfully employed in space and automotive applications for some time. This, he says, is where the Alleima expertise comes into play.

A “head start” in hydrogen

"At Alleima, we have been supplying tubing and raw materials for the space and automotive segments for many years,” says Guyon. “We already have the alloys that have been tried and tested in the field and are proven to be suitable for use with hydrogen applications".

“If any company is looking for a hydrogen fuel materials expert that can support new development projects, Alleima is that expert,” he continues.

Alleima is also well positioned to contribute to a more stable supply chain.

“We have a fully integrated mill where everything is manufactured by Alleima from melting through to the end product,” says Guyon. “Ours is one of the most secure production routes in the business, and are doing everything in our power to make sure our customers are not impacted by irregular supplies from volatile markets.”

Regional footprint and sustainable vision

Our robust supply is further enhanced by its strong regional footprint.

“We are constantly striving to be as close as possible to our aerospace customers in different regions of the world,” explains Hedvall. “Our integrated, high-quality production gives us a very strong position in the tubular aerospace industry.”

Alleima is also a sustainable supplier. Its efforts to limit environmental impact range from material recycling programs to initiatives designed to improve energy efficiency and reduce water consumption and raw material use, as well as an advanced regeneration strategy.

“Sustainability is part of our DNA,” explains Guyon. “From developing the materials for some of the world’s most advanced sustainable technologies to minimizing the impact of our own processes, it is at the very core of our strategy and promise for the future.”