Damax™ by Alleima is the next generation of Damascus knife steel. It features the same quality as handcrafted steel and is produced with an innovative industrialized technique with up to 135 layers of martensitic stainless steel. The large scale production offers a more cost efficient material with repeatable quality.

Damax™ is a stainless Damascus steel. After heat treatment, the grade is characterized by:

- Layered structure with aesthetic design possibilities

- Very high hardness

- Good corrosion resistance

Damax™ Damascus steel is a multilayered steel, built up by two different steel grades that will give a different appearance after chemical etching. The steel grades in Damax™ are Alleima® 7C27Mo2 and Alleima® 19C27.

Chemical composition

Damax™ is a mixture of the two grades Alleima® 7C27Mo2 and Alleima® 19C27.

Chemical composition (average), weight%

| C | Si | Mn | P | S | Cr | Mo | |

| Alleima® 7C27Mo2 | 0.38 | 0.4 | 0.6 | ≤0.025 | ≤0.010 | 13.5 | 1.0 |

| Alleima® 19C27 | 0.95 | 0.4 | 0.7 | ≤0.025 | ≤0.010 | 13.5 | |

| Damax™ | 0,67 | 0,4 | 0,6 | ≤0.025 | ≤0.010 | 13,5 | 0,5 |

Applications

Applications of Damax™ Damascus steel are knives, such as kitchen or outdoor knives, but can also be used for jewelry or other decorative applications.

Forms of supply

Strip can be supplied either in coils or as straightened lengths of 0.5 - 3.0 meters (1.6 - 13.1 feet / 20- 118 inches). The coil weight is max. 4.3 kg/mm (241 lbs/in.) of strip width.

| Thickness | Width | ||

|---|---|---|---|

| mm (in.) | mm (in.) | ||

| Min. | Max | Min. | Max. |

| 2.5 (0.098) | 4.0 (0.157) | 30 (1.18) | 270 (10.63) |

| Other sizes might be supplied to meet specific requirements. | |||

Tolerances

The thickness and width tolerances are +/- tolerances to the nominal size. The following tolerances are valid for cold rolled material with slit edges.

Width: ± 0.60 mm

Thickness: ± 0.065 mm

Tighter tolerances, as well as other tolerance limits can be offered upon request.

| As-delivered | Tensile strength | Hardness * | |

|---|---|---|---|

| MPa (ksi) | HV | HRB | |

| Soft annealed | nominal 700 (102) | nominal 215 | nominal 95 |

| Annealed | 750 ± 100 (109 ± 14) | 235 ± 35 | 97.5 ± 6 |

| Cold rolled | 800-1000 (116-145) | 250-315 | 99.5-108.5 |

| * Hardness data is for guidance only. | |||

Hardening and tempering of the strip steel is needed to achieve the correct condition and to meet the properties required by the end user.

Physical properties

The physical properties of a steel are related to a number of factors, including alloying elements, heat treatment and manufacturing route, but the data presented below can generally be used for rough calculations.

| Density | |

|---|---|

| g/cm3 | 7.7 |

| lb/in.3 | 0.28 |

Heat treatment

Hardening data

The exact hardening parameters need to be adjusted in every individual furnace. A general recommendation is given below:

Austenitizing:

Piece hardening

To room temperature: Recommended temperature: 1060°C (1940°F)

Deep freezing to -70°C: Recommended temperature: 1090°C (1994°F)

| Time in furnace according to table | ||

| Thickness (mm) | Thickness (in.) | Time (minutes) |

| 2.5 | 0.100 | 5 |

| 3.0 | 0.118 | 6 |

| 3.25 | 0.128 | 7 |

| 3.5 | 0.138 | 8 |

| 3.75 | 0.148 | 10 |

| 4 | 0.157 | 12 |

Batch hardening

To room temperature: Recommended temperature: 1050°C (1922°F)

Deep freezing to -70°C: Recommended temperature: 1080°C (1976°F)

Soaking time 30 minutes in furnace. The temperature should first be equalized at 850°C (1560°F) for 30 minutes to avoid necessary temperature variations.

Quenching

Quench to room temperature as rapid as possible. For optimum results 600°C (1110°F) should be reached within 2 minutes or less.

Tempering

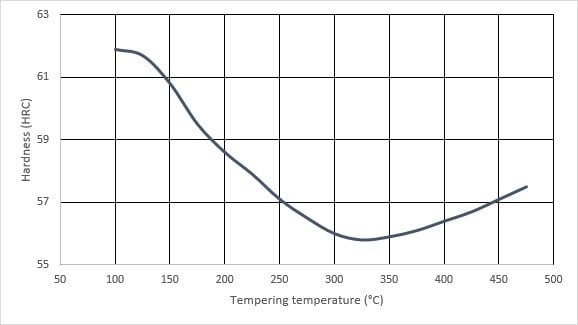

It is recommended that tempering is performed between 175-350°C (345-660°F) for 0,5-2 hours. Brittleness occurs with tempering above 450°C (840°F).

Typical tempering curve after austenitizing at 1060°C and quenching to room temperature.

Below is an estimation of the hardness levels that can be expected with different tempering temperatures.

After quenching to room temperature:

| Hardness | Temperature |

| 59 HRC | 175°C (345°F) |

| 58 HRC | 225°C (435°F) |

| 56 HRC | 350°C (660°F) |

After deep-freezing:

| Hardness | Temperature |

| 62 HRC | 175°C (345°F) |

| 60 HRC | 225°C (435°F) |

| 58 HRC | 350°C (660°F) |

Read more about the importance of using the right hardening parameters, and find additional recommendations regarding hardening in Alleima's hardening guide.

Damascus pattern

The Damax steel is normally manufactured with up to 135 layered Damascus billet. Other number of layers can be an option upon request. After grinding the material will have a striped appearance.

To give it some other pattern of the customer’s own design, a cold or hot embossing followed by grinding needs to be performed.

Etching

To reveal the pattern an etching of the finished product has to be performed.

Before etching the surface must be polished to a smooth finish and degreased to remove all oils residuals.

Various acids can be used for the etching, but we recommend the following:

- Sulfuric acid, H2SO4 (15-20%)

Immerse the product in the acid for approximately 10 minutes, or until the pattern appear to a desired level. Heating of the solution in a water bath to about 50°C (122°F) can accelerate the process. Normal safety precautions for handling acids must be taken.

After etching all traces of the acid must be removed. Rinse thoroughly in water. It can also be neutralized in a mixture of water and baking soda (sodium bicarbonate).

The contrast of the layers can be even further enhanced by a second polishing or very fine grinding operation of the etched surface.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.