Alleima® 19C27 is a martensitic stainless chromium steel with high carbon content. After heat treatment the grade is characterized by:

- Very high hardness

- Very good wear resistance

Alleima® 19C27 is mainly used for industrial knives for cutting synthetic fibre, paper and plastic films.

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr |

|---|---|---|---|---|---|

| 0.95 | 0.4 | 0.7 | ≤0.025 | ≤0.010 | 13.5 |

Forms of supply

The strips can be supplied either in coils or as straightened lengths of 0.5-4.0 meter (1.6-13.1 feet). The coil weight is max. 5 kg/mm (280 lbs/in.) of strip width.

Hardening and tempering of the strip steel is needed to achieve the correct finish and to meet the properties required by the end user.

| Thickness | Width | ||

|---|---|---|---|

| mm (in.) | mm (in.) | ||

| Min. | Max | Min. | Max. |

| 0.1 (0.0039) | 3.0 (0.118) | 5 (0.197) | 340 (13.39) |

Other sizes can be supplied to meet specific requirements.

Tolerances

The thickness and width tolerances are +/- tolerances to the nominal size. The normal tolerance classes for most of our strip products are T2 and B1. Tighter tolerances as well as other tolerance limits can be offered upon request.

| As-delivered | Tensile strength | Hardness | HRB |

|---|---|---|---|

| MPa (ksi) | HV | ||

| Annealed | max. 800 (116) | max. 275 | max 103 |

| Cold rolled | 850-1000 (123-160) | 265-345 | 101.4-108.7 |

Heat treatment

Hardening data

Hardening temperature 1060°C (1940°F), strip thickness 1.0 mm (0.039 in.), holding time 3 minutes, quenching in oil.

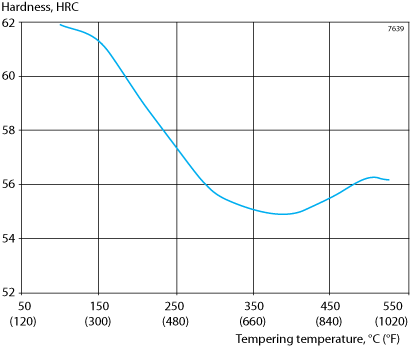

Tempering data

Tempering time 30 minutes.

Brittleness occurs with tempering above 450°C (840°F).

Additional recommendations regarding hardening can be found in Alleima's hardening guide.

The following figures show the importance of using the right hardening conditions to optimize the microstructure and properties.

Too high hardening temperature gives coarse structure, high austenite content (30%), few carbides. Consequence: low hardness and bad wear resistance.

Too high hardening temperature gives coarse structure, high austenite content (30%), few carbides. Consequence: low hardness and bad wear resistance.

Too low cooling rate after austenitizing gives carbide precipitations in the grain boundaries. Consequence: brittleness and reduced corrosion resistance.

Too low cooling rate after austenitizing gives carbide precipitations in the grain boundaries. Consequence: brittleness and reduced corrosion resistance.

Optimized hardening conditions give optimal austenite content (15%), many uniformly distributed carbides. Consequence: optimal combination of hardness, wear resistance, ductility and corrosion resistance.

Optimized hardening conditions give optimal austenite content (15%), many uniformly distributed carbides. Consequence: optimal combination of hardness, wear resistance, ductility and corrosion resistance.

How the hardening parameters affect the product properties

- Too high hardening temperature gives low hardness and bad wear resistance due to excessive content of retained austenite.

- A low hardening temperature gives low hardness and reduced corrosion resistance.

- Too long holding time at the optimal hardening temperature increases the amount of retained austenite and lowers the hardness.

- Too short holding time at the optimal hardening temperature has the same effect as low austenitizing temperature.

- The maximum hardness will be obtained at a retained austenite content of about 15%.

- Deep freezing, i.e. cooling to below room temperature, increases the hardness by about 1–2 HRC.

- With deep freezing, the highest possible hardness will be achieved by increasing the hardening temperature. Read more in the Alleima hardening guide.

- High cooling rate after hardening is necessary to avoid brittleness and reduced corrosion resistance. 600°C (1112°F) should be reached within 1–2 minutes and room temperature within 30 minutes.

- Rehardening is generally not recommended as it will not give optimal product properties.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.