Alleima® SAF 2205™ SH is a duplex (austenitic/ferritic) stainless steel with super high tensile strength.

The grade is characterized by:

- Very good corrosion resistance

- High resistance to stress corrosion cracking in chloride-bearing environments

- High resistance to stress corrosion cracking in environments containing hydrogen sulphide

- High resistance to general corrosion, pitting, and crevice corrosion

- High resistance to erosion corrosion and corrosion fatigue

- Extremely high tensile strength in 'as delivered' condition

- Very good relaxation resistance

- Physical properties that offer design advantages

Service temperature: -100 to 300°C (-150 to 570°F)

Service temperature: -200 to 280°C (-330 to 540°F)

Standards

- UNS: S32205/S31803

- EN Number: 1.4462

- EN Name: X2CrNiMoN22-5-3

- W.Nr.: 1.4462

Applications

Alleima® SAF 2205™ SH can be used for dental instruments.

Chemical composition (nominal) %

| C | Si | Mn | P | S | Cr | Ni | Mo | N |

|---|---|---|---|---|---|---|---|---|

| ≤0.030 | ≤0.5 | ≤0.9 | ≤0.030 | ≤0.015 | 22 | 5.0 | 3.2 | 0.18 |

Forms of supply

Surface conditions and dimensions

| Surface finish | Dimension, mm | in. |

|---|---|---|

| Coated | 0.4 – 3.0*) | 0.016-0.118*) |

| Bright | 0.20 – 0.80 | 0.008-0.031 |

| Polished | 0.4 - 1.0 | 0.016-0.039 |

| Degreased | 0.4-3.0*) | 0.016-0.118*) |

*) Dimensions >1 mm on request only

Delivery forms

Wire is delivered in lots and forms according to customers´ requirements:

- On various types of spool with wire weights up to 500 kg (1100 lb)

- In straightened lengths 0.45 to 4 m (1.5 to13 ft)

Mechanical properties

At 20°C (68°F)

| Wire diameter | Nominal, Rm | Nominal Rp0.2 | |||

|---|---|---|---|---|---|

| mm | in. | +/- 100 MPa | +/- 15 ksi | MPa | ksi |

| 0.20 – 0.70 | 0.0079 - 0.028 | 2550 | 370 | 2050 | 297 |

| >0.70 - 0.80 | >0.028 - 0.031 | 2400 | 348 | 2000 | 290 |

| >0.80 - 1.00 | >0.031 - 0.039 | 2300 | 334 | 1950 | 283 |

| >1.00 - 1.50 | >0.039 - 0.059 | 2250 | 326 | 1915 | 278 |

| >1.50 - 2.00 | >0.059 - 0.079 | 2150 | 312 | 1800 | 261 |

| >2.00 - 2.50 | >0.079 - 0.098 | 2050 | 297 | 1745 | 253 |

| >2.50 - 3.00 | >0.098 - 0.118 | 2000 | 290 | 1700 | 247 |

1) Rp0.2 corresponds to 0.2% offset yield strength.

2) Dimensions >1 mm on request only

Tensile strength can be increased by 200 MPa (29 ksi) up to 450 MPa (65 ksi) by tempering depending on tensile and tempering conditions. Please see heat treatment for further information. The tensile strength variation between spools/coils within the same production lot is ±50 MPa (7 ksi) maximum. Yield strength in the tempered condition is approx. 90 % of the tempered tensile strength. Tensile strength values are guaranteed and are measured directly after production. During storage, both the tensile strength and yield strength will increase somewhat due to ageing. Depending on the storage conditions, the tensile strength can increase by 0 - 80 MPa (0 - 12 ksi).

The tensile strength and yield strength will decrease by 3–4% per 100°C (210oF) increase in service temperature.

Straightened lengths

Straightening will reduce the tensile strength by approx. 7 %.

Fatigue strength

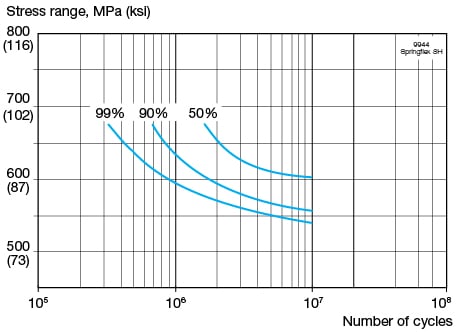

The diagrams below are based on tempered and pre-stressed cylindrical helical springs with a wire surface free from tooling damage.

At elevated temperatures, the fatigue strength decreases at

100°C (210°F): by about 5 %

200°C (390°F): by about 10 %

Figure 1.Wöhler diagram, mean stress 450 MPa (65 ksi). The curves are valid for springs coiled from wire 1.00 mm (0.039 in.) in diameter and represents 50%, 90% and 99% certainty against failure. Stress range = double the stress amplitude

Figure 1.Wöhler diagram, mean stress 450 MPa (65 ksi). The curves are valid for springs coiled from wire 1.00 mm (0.039 in.) in diameter and represents 50%, 90% and 99% certainty against failure. Stress range = double the stress amplitude

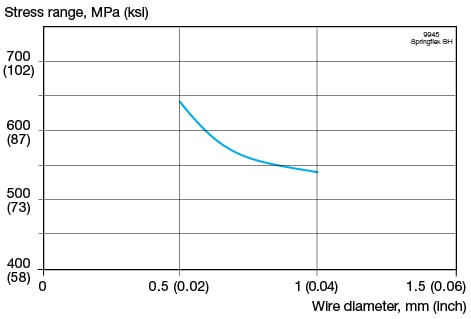

Figure 2. Stress range for different wire diameters, mean stress 450 MPa (65 ksi). Stress range at 10<sup>7</sup> load cycles as a function of the wire diameter and 90% certainty against failure.

Figure 2. Stress range for different wire diameters, mean stress 450 MPa (65 ksi). Stress range at 10<sup>7</sup> load cycles as a function of the wire diameter and 90% certainty against failure.

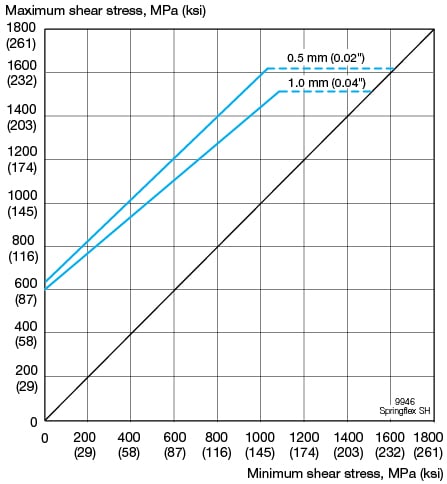

Figure 3. Modified Goodman diagram for different wire diameters. The curves are valid for 10<sup>7</sup> load cycles and represent 90 % certainty against failure.

Figure 3. Modified Goodman diagram for different wire diameters. The curves are valid for 10<sup>7</sup> load cycles and represent 90 % certainty against failure.

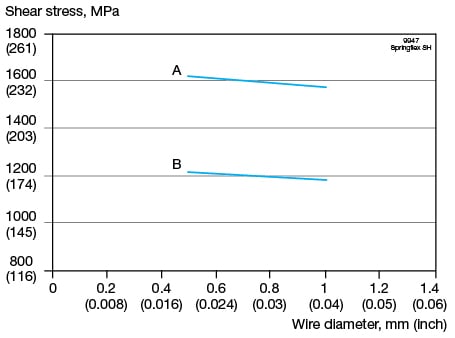

Figure 4. Setting limit and maximum permissible shear stress. Setting limit curve A, and maximum permissible shear stress, curve B, as a function of the wire diameter. The setting limit is defined as the shear stress at which the relaxation is 2% after a load time of 24 hours. Curve B lies 25% below curve A.

Figure 4. Setting limit and maximum permissible shear stress. Setting limit curve A, and maximum permissible shear stress, curve B, as a function of the wire diameter. The setting limit is defined as the shear stress at which the relaxation is 2% after a load time of 24 hours. Curve B lies 25% below curve A.

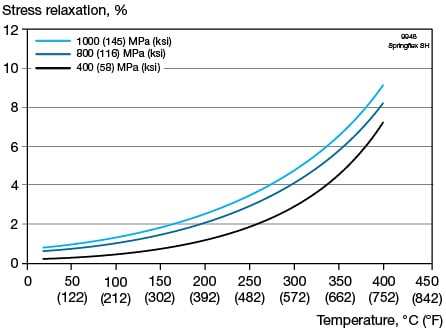

Figure 5. Relaxation 24 hours. Relaxation (load loss) at various shear stresses as a function of service temperature. This diagram refers to a wire diameter of 1.0 mm (0.039 in.).

Figure 5. Relaxation 24 hours. Relaxation (load loss) at various shear stresses as a function of service temperature. This diagram refers to a wire diameter of 1.0 mm (0.039 in.).

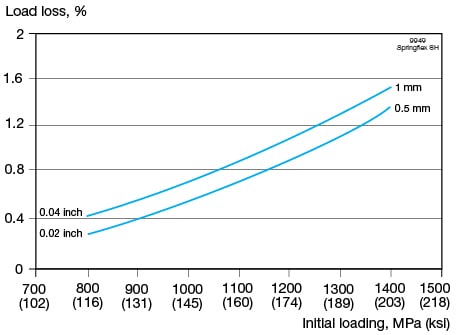

Fig 6. Relaxation, 24 hours. Relaxation (load loss) at various shear stresses as a function of wire diameter.

Fig 6. Relaxation, 24 hours. Relaxation (load loss) at various shear stresses as a function of wire diameter.

Physical properties

Density: 7.8 g/cm3, 0.28 lb/in3

| 500 J/kg °C | in the temperature range 50 - 100°C |

| 0.12 Btu/lb °F | in the temperature range 120 - 212°F |

| Temperature, °C | W/m °C | Temperature, °F | Btu/ft h °F |

|---|---|---|---|

| 20 | 14 | 68 | 9 |

| 100 | 16 | 212 | 9 |

| 200 | 17 | 390 | 10 |

| 300 | 19 | 570 | 11 |

| Temperature, °C | μΩm | Temperature, °F | μΩin. |

|---|---|---|---|

| 20 - 100 | 0.84 | 120 - 212 | 33 |

Thermal expansion

Mean values in temperature ranges (x10-6)

Cold worked

| Temperature, °C per °C | 30-100 | 30-200 | 30-300 | 30-400 |

|---|---|---|---|---|

| 12.5 | 11.5 | 11.5 | 12.0 |

| Temperature, °F per °F | 86-200 | 86-400 | 86-600 | 86-800 |

|---|---|---|---|---|

| 7.0 | 6.5 | 6.5 | 6.5 |

Aged

| Temperature, °C per °C | 30-100 | 30-200 | 30-300 | 30-400 |

|---|---|---|---|---|

| 13.0 | 13.5 | 13.5 | 14.0 |

| Temperature, °F per °F | 86-200 | 86-400 | 86-600 | 86-800 |

|---|---|---|---|---|

| 7.0 | 7.5 | 7.5 | 8.0 |

| Magnetic permeability, μmax | ||

|---|---|---|

| Annealed | 60 | |

| Cold drawn | 120 | |

Shear modulus, MPa (ksi)

as delivered: approx 77 000 (11 165)

tempered: approx 80 000 (11 600)

Modulus of elasticity, MPa (ksi)

as delivered: approx 200 000 (29 000)

tempered: approx 208 000 (30 160)

Corrosion resistance

Chloride induced corrosion

In seawater and other high chloride content environments, Alleima® SAF 2205™ SH has better corrosion resistance than stainless steel of type ASTM 316 because of its high PRE number (Pitting Resistance Equivalent, a parameter for comparing the resistance of different steels to pitting). The PRE number is defined as, in weight-%: PRE = % Cr + 3.3 x % Mo + 16 x % N. The better resistance of Alleima® SAF 2205™ SH can be demonstrated by e.g. salt spray testing, where samples are sprayed with water containing 5 % NaCl at 35°C (95oF) and checked every 24 hours. See the diagram below.

Neutral salt spray test according to ASTM B 117

Testing time, hours Critical pitting temperature

Critical pitting temperature

In high saline content environments such as salt water, the aggressiveness of the environment increases as the temperature rises. All stainless steels have a critical pitting temperature above which there is a risk of pitting. The critical pitting temperature for Alleima® SAF 2205™ SH and ASTM 316, as a function of chloride concentrations, is shown in the diagram.

Crevice corrosion

Crevice corrosion is, in principle, the same as pitting corrosion, but occurs in crevices and cracks, e.g. between flange joints, under deposits on the metal surface or in welds with incomplete penetration. Crevice corrosion often occurs at lower temperatures and at lower chloride contents than those necessary for pitting to occur. Resistance is influenced by the content of Cr, Mo and N in the same way as pitting resistance.

Stress corrosion cracking

Stress corrosion cracking leading to catastrophic failure might occur with standard austenitic steels. Alleima® SAF 2205™ SH, thanks to its duplex structure, is significantly more resistant to this type of corrosion.

Bending

The minimum bending radius should not be less than half the wire diameter. The wire surface should be free from any tooling damage because slight imperfections in the surface can lead to fracture, even at large bending radii.

Heat treatment

Spring tempering will increase the tensile strength by 200 MPa (29 ksi) up to to 450 MPa (65 ksi) depending on tensile and tempering conditions.

We recommend 450°C (840°F) / 1–3 h for batch tempering. To obtain best results, when tempering in a continuous conveyor furnace, where holding time at full temperature is very short, the temperature should be increased preferably to about 500°C (930°F). The holding time should be 3 - 10 minutes. Shorter times may result in uneven tempering.

Disclaimer: Alleima is not providing any products or services that are intended or may be construed to be recommending or otherwise advising on, in any manner, the design, suitability, appropriateness or effectiveness, from a medical/biological/safety perspective, of any medical material, instrument and/or medical device.