Sanicro® 48 is an austenitic nickel-base alloy for highly corrosive OCTG downhole applications. The grade is characterized by:

- Excellent resistance to sulfide stress cracking and stress corrosion cracking (SCC) in chloride and sour (H2S/Cl) environments

- Very high resistance to pitting and crevice corrosion

Standards

- UNS: N06985

Product standards

| Seamless tubes used as casing, tubing and coupling stock: | ISO 13680, PSL-1 and PSL-2 |

| API spec 5CRA |

Approvals

- NACE MR0175/ISO 15156-3 (Petroleum and natural gas industries - Materials for use in H2S-containing environments in oil and gas production)

- Sanicro® 48, grade 110 ksi and grade 125 ksi, can be delivered with API-5CRA Monogram (License Number 5CRA-0016)

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Fe | Mo | Co | Cu | Nb + Ta | W |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ≤0.015 | ≤0.5 | ≤1.00 | ≤0.02 | ≤0.01 | 21.0 - 23.0 | 18.0 - 21.0 | 6.5 - 7.5 | ≤1.0 | 1.5 - 2.3 | ≤0.5 | ≤1.5 |

Balance Ni

Applications

Sanicro® 48 is used for high strength downhole production tubing, casing, and liners in sour gas wells. This includes environments with high temperatures, high partial pressures of CO2 and H2S, high chloride concentrations, low pH, and the presence of elemental sulfur.

Corrosion resistance

Pitting Corrosion

Sanicro® 48 can withstand high temperatures in aggressive environments without pitting. A recognized method of ranking a material's susceptibility to localized corrosion is by means of the PRE number (Pitting Resistance Equivalent). This PRE number is based on the contents of chromium, molybdenum, tungsten, and nitrogen in the alloy according to the following formula:

PRE = %Cr + 3.3 × (%Mo + 0.5 × %W) + 16 × %N

A PRE number is the relative measure of a material's ability to resist pitting corrosion in chloride-containing environments. Sanicro® 48 has a minimum PRE number of 45, which confirms its very high resistance to pitting corrosion when chlorides are present.

Critical pitting (CPT) was determined on cold worked Sanicro® 48 in two different test solutions. Specimens representing the tube surface were tested using modified ASTM G150. The temperature of the test solution was started at 20°C, and heated at a rate of 1°C/min. The tests were carried out in a 3M MgCl2 solution. The assessments were carried out at a potential of +734 mV vs. Ag/AgCl on duplicate specimens for three different tube dimensions.

Ground coupons were tested according to ASTM G150 with the test solution 1M NaCl, a starting temperature of 20°C, and a heating rate of 1°C/min. The potential was +734 mV vs. Ag/AgCl.

The high CPT measured to 55°C in the more severe test solution of 3M MgCl2 and 71°C in 1M NaCl solution suggest a very high pitting corrosion resistance of the material in the environments tested.

Stress Corrosion Cracking (SCC)

Environmental assisted cracking, especially in the presence of hydrogen sulfide (H2S), is one of the more serious forms of corrosion in sour environments. Failure of tubing by environmentally assisted cracking can occur rapidly without any warning. For that reason, the prevention of this form of corrosion must be considered when selecting tubing materials for sour wells.

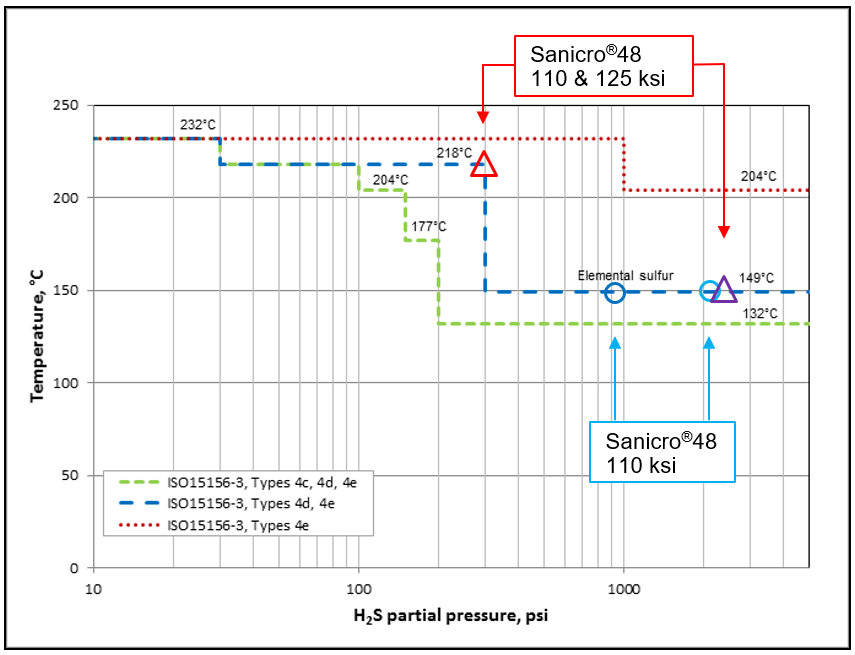

According to ISO 15156-3 (2020), cold worked Sanicro® 48 belongs to type 4d material which can be safely used in the limited environmental combinations of temperature and H2S in order to avoid the risk of SCC. Laboratory test data shows that cold worked Sanicro® 48 tube materials are not susceptible to SCC in sour environmental limits covered by 4d materials.

Figure 1 illustrates SCC testing on Sanicro® 48 in Cl-H2S-CO2 environments with and without elemental sulfur in comparison with ISO 15156-3 limits for type 4c materials (under the green dashed line), type 4d materials (under the blue dashed line), and type 4e materials (under the red dashed line). The SCC testing has been performed on cold worked Sanicro® 48, minimum yield strength 110 ksi & 125 ksi, using slow strain rate test (SSRT) per NACE TM0198 at a strain rate of 4×10-6 1/sec and C-ring per NACE TM0177 method C stressed at 90% of actual yield strength (AYS). Crevice corrosion resistance and corrosion rate by mass loss were also included in the autoclave test for the C-rings. Sanicro® 48 showed good ductility in the tested sour environments without cracking, pitting, or crevice corrosion.

| Temp | Rp0.2 | ppH2S | ppCO2 | Chlorides | HCO3 | Elem. sulfur | SCC SSRT | SCC C-ring (90 d) |

Crevice, Corr rate (90 d) |

|

| °C | ksi | psi | psi | mg/l | mg/l | g/l | mm/yr | |||

A |

218 | 110 | 300 | 1 000 | 180 000 | 0 | 0 | Pass | ÷ | ÷ |

B |

218 | 125 | 300 | 1 000 | 180 000 | 0 | 0 | Pass | ÷ | ÷ |

C |

149 | 110 | 2 200 | 1 000 | 180 000 | 0 | 1 | Pass | ÷ | ÷ |

D |

149 | 125 | 2 200 | 1 000 | 180 000 | 0 | 1 | Pass | ÷ | ÷ |

E |

143 | 110 | 918 | 357 | 170 000 | 140 | 0 | Pass | Pass | <0.001 |

F |

149 | 110 | 2 061 | 613 | 52 000 | 395 | 100 | Pass | Pass | <0.001 |

Fabrication

Sanicro® 48 tubes are supplied in cold-worked condition and are primarily intended for use with threaded connections.

Forms of supply

Materials for oil and gas production

Cold hardened (cold worked) seamless tube and pipe

For production tubing, casing, liner, and coupling stock for downhole oil and gas applications, Sanicro® 48 is supplied cold hardened with high strength properties (Sanicro® 48 -110ksi, -125ksi).

Full details on sizes, finishes, and mechanical properties are available on request.

Email: stog.smt@alleima.com

Heat treatment

Tubes for downhole oil and gas applications are delivered in the high strength, cold hardened condition. They are not annealed after cold working.

Mechanical properties

At 20°C (68°F), metric and imperial units

| Grade | Proof strength, Rp0.2a) | Tensile strength, Rm | Elong. | Hardness | ||

| MPa | ksi | MPa | ksi | A2", % | HRC | |

| PSL-1 Sanicro® 48-110 | 760-965 | 110-140 | ≥795 | ≥115 | ≥11 | ≤35 |

| PSL-1 Sanicro® 48-125 | 860-1035 | 125-150 | ≥895 | ≥130 | ≥10 | ≤37 |

| PSL-2 Sanicro® 48-110 | 760-965 | 110-140 | ≥795 | ≥115 | ≥11 | ≤35 |

| PSL-2 Sanicro® 48-125 | 860-1035 | 125-150 | ≥895 | ≥130 | ≥10 | ≤37 |

1 MPa = 1 N/mm2

a) Rp0.2 corresponds to 0.2% offset yield strength.

At high temperatures

Cold-worked Sanicro® 48 also displays very good mechanical properties at higher temperatures. Further information is available on request. Email:stog.smt@alleima.com

| Temperature, °C |

De-rating factor* | Temperature, °F |

De-rating factor* |

| 20 | 1.00 | 68 | 1.00 |

| 100 | 0.95 | 200 | 0.95 |

| 120 | 0.93 | 250 | 0.93 |

| 150 | 0.92 | 300 | 0.92 |

| 180 | 0.91 | 350 | 0.91 |

| 220 | 0.90 | 400 | 0.90 |

* Approximate yield strength at temperature is received by multiplying the corresponding de-rating factor and yield strength at 20°C (68°F).

Impact strength

Due to its austenitic microstructure, Sanicro® 48 has very good impact strength, both at room temperature and at lower temperatures. Tests have demonstrated that the alloy readily fulfills the requirements in accordance with ISO 13680 and API Spec 5CRA.

.

Physical properties

Physical properties of cold-worked Sanicro® 48.

Density: 8.21 g/cm3, 0.297 lb/in3

Relative magnetic permeability

1.003 (approximate value)

| Metric units | Imperial units | ||

| Temperature, °C | W/(m °C) | Temperature, °F | Btu/(ft h °F) |

|---|---|---|---|

| 20 | 10 | 68 | 5.6 |

| 50 | 10 | 100 | 5.8 |

| 100 | 11 | 200 | 6.4 |

| 150 | 12 | 300 | 7.0 |

| 200 | 13 | 400 | 7.5 |

| 250 | 14 | 500 | 8.1 |

| 300 | 15 | 600 | 8.7 |

| Metric units | Imperial units | ||

| Temperature, °C | J/(kg °C) | Temperature, °F | Btu/(lb °F) |

|---|---|---|---|

| 20 | 435 | 68 | 0.10 |

| 50 | 443 | 100 | 0.11 |

| 100 | 457 | 200 | 0.11 |

| 150 | 468 | 300 | 0.11 |

| 200 | 478 | 400 | 0.11 |

| 250 | 488 | 500 | 0.12 |

| 300 | 497 | 600 | 0.12 |

| Metric units | Imperial units | ||

| Temperature, °C | MPa | Temperature, °F | ksi |

|---|---|---|---|

| 20 | 195 | 68 | 28 |

| 100 | 195 | 200 | 28 |

| 150 | 195 | 300 | 28 |

| 220 | 195 | 400 | 28 |

1) (×103)

Poisson's ratio

The Poisson's ratio is 0.31 for Sanicro® 48 at room temperature.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.