Sanicro® 41 is a nickel alloy characterized by the following properties:

- Very good resistance to stress corrosion cracking (SCC) in chloride and sour (H2S/Cl-) environments

- Very good resistance to corrosion in acidic media such as sulfuric acid

- Superior resistance to pitting and crevice corrosion than steels of the ASTM 316 type

- Good weldability

Standards

- ASTM: Alloy 825

- UNS: N08825

- W.Nr.: 2.4858

- DIN: NiCr 21 Mo

Product standards

Seamless tube and pipe, seamless heat exchanger tubes.

- ASTM B163, ASTM B423

- ASME SB-163, ASME SB-423

Approvals

- Approved by the American Society of Mechanical Engineers (ASME) for use in accordance with ASME Boiler and Pressure Vessel Code, Section I and Section VIII, div. 1, and Division 2, Class 1 and Class 2.

- ASME B&PV Code Section III, Division 1, Classes 1 and 3.

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Mo | Ti | Cu |

|---|---|---|---|---|---|---|---|---|---|

| ≤0.030 | ≤0.5 | 0.8 | ≤0.025 | ≤0.010 | 20 | 38.5 | 2.6 | 0.7 | 1.7 |

Applications

Sanicro® 41 is particularly suited for use in heat exchangers for crude oil and oil refineries, especially where high concentrations of hydrogen sulphide and chloride are present.

Corrosion resistance

General corrosion

Sanicro® 41 possesses excellent resistance to corrosion. The material is far superior to molybdenum alloyed steels such as AISI 316L, particularly when exposed to non-oxidizing media such as sulfuric acid or phosphoric acid. It also has satisfactory resistance to highly oxidizing agents such as nitric acid. Sanicro® 41 has significantly better corrosion resistance in formic acid than standard austenitic stainless steels.

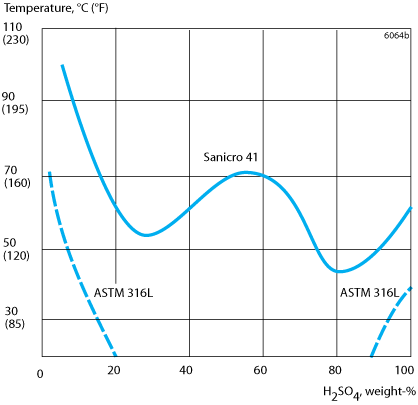

The results of corrosion tests in nitric acid are tabulated below. Resistance to sulfuric acid is illustrated in Figure 1. It should be noted that the corrosiveness of sulfuric acid depends on the oxygen content. Sulfuric acid in contact with air is, therefore, more corrosive than deaerated acid.

Table 1. General corrosion resistance of Sanicro® 41 in nitric acid.

| Concentration | Temperature | |||||

|---|---|---|---|---|---|---|

| Nitric acid | (Boiling solution) | Sanicro 41 | AISI 316L | |||

| wt % | oC | oF | mm/year | mpy | mm/year | mpy |

| 50 | 115 | 240 | 0.04 | 1.6 | 0.12 | 4.8 |

| 65 | 118 | 245 | 0.11 | 4 | 0.3 | 12 |

Figure 1. Isocorrosion diagram for Sanicro 41 and AISI 316L in deaerated sulphuric acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy).

Figure 1. Isocorrosion diagram for Sanicro 41 and AISI 316L in deaerated sulphuric acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy).

Weight-% H2SO4

Pitting and crevice corrosion

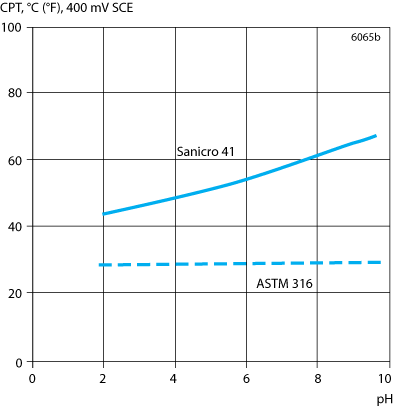

Corrosion tests carried out in sodium chloride solutions indicate that the resistance of Sanicro® 41 to pitting and crevice corrosion is superior to that of AISI 316- a result of the higher chromium and molybdenum contents of the material. Critical pitting temperatures (CPT) for the two grades in 3% sodium chloride solutions at different pH values are plotted in Figure 2.

Figure 2. Critical pitting temperatures for Sanicro 41 and AISI 316 in 3 % NaCl solutions at different pH values.

Figure 2. Critical pitting temperatures for Sanicro 41 and AISI 316 in 3 % NaCl solutions at different pH values.

pH

Stress corrosion cracking

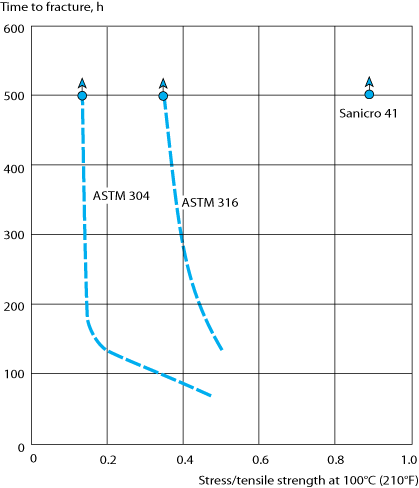

The high nickel content of the material promotes excellent resistance to stress corrosion cracking induced by both chlorides and alkalis. The results of stress corrosion cracking tests in 40 % calcium chloride are shown in Figure 3.

Sanicro® 41 displays excellent resistance to stress corrosion cracking in sour environments. Tests carried out at the Nickel Development Institute (NIDI), concluded that Sanicro® 41 could be used in sour environments up to 260oC with H2S contents corresponding to a partial pressure of up to 10000 psi, in the absence of elementary sulfur. The material also shows some immunity to all concentrations of CO2, according to NIDI. Sanicro 41 is used in the oil and gas industry in environments up to 200oC (392oF), a 60 psi partial pressure of H2S and with chlorides present.

According to ISO 15156/NACE MR0175 it is acceptable for use in the cold worked and annealed condition with no environmental limits in respect of partial pressures of H2S or elemental sulfur.

Figure 3. Results of stress corrosion cracking tests in 40 % CaCl<sub>2</sub> at 100 <sup>o</sup>C (210 <sup>o</sup>F), pH=6.5.

Figure 3. Results of stress corrosion cracking tests in 40 % CaCl<sub>2</sub> at 100 <sup>o</sup>C (210 <sup>o</sup>F), pH=6.5.

Stress/tensile strength at 100oC (210oF)

Intergranular corrosion

Even in the heaviest sizes, Sanicro® 41 can be welded without the risk of carbide precipitation causing intergranular corrosion. This is due, in part, to the low carbon content of the material, but also to the fact that it is titanium stabilized.

Bending

The excellent formability of Sanicro® 41 enables the material to be cold bent to extremely small radii. Annealing after bending is not normally necessary.

Forms of supply

Seamless tube and pipe- finishes and dimensions

Heat exchanger tubing, straight or bent to specification, with or without heat treatment of bends, can be supplied.

Seamless tube and pipe in Sanicro® 41 can be supplied in dimensions up to 260 mm (10") outside diameter. The delivery condition is solution annealed and either white pickled or bright annealed.

Materials for oil and gas production

Cold worked seamless tube and pipe:

For production tubing and casing in oil and gas production, Sanicro® 41 is supplied cold worked with high strength properties (Sanicro 41-110).

Size range:

Outside diameter: 2 3/8" - 7" (60.33-177.8 mm)

Wall thickness: 0.190"-0.590" (4.83-14.99 mm)

Heat treatment

Tubes are delivered in the heat treated condition. If additional heat treatment is needed due to further processing, the following is recommended.

Solution annealing

1000-1100 oC (1830-2010 oF), 5-10 minutes, rapid cooling in air or water.

Mechanical properties

At 20oC

Metric units

| Condition | Proof strength | Tensile strength | Elongation | Hardness |

|---|---|---|---|---|

| Rp0.21) | Rm | A2" | HRB | |

| MPa | MPa | % | ||

| Cold finished | ≥241 | ≥586 | ≥30 | ≤90 |

| Hot finished | ≥172 | ≥517 | ≥30 | ≤90 |

At 68oF

Imperial units

| Condition | Proof strength | Tensile strength | Elongation | Hardness |

|---|---|---|---|---|

| Rp0.21) | Rm | A2" | HRB | |

| ksi | ksi | % | ||

| Cold finished | ≥35 | ≥86 | ≥30 | ≤90 |

| Hot finished | ≥25 | ≥75 | ≥30 | ≤90 |

1) Corresponds to 0.2% offset yield strength

At high temperatures

The alloy, UNS N08825, is approved under ASME Pressure Vessel Code, div. 1, Section VIII for use up to 538oC (1000oF).

Metric units

| Temperature | Proof strength |

|---|---|

| Rp0.2 | |

| oC | MPa |

| min | |

| 100 | 220 |

| 150 | 210 |

| 200 | 201 |

| 250 | 193 |

| 300 | 186 |

| 350 | 181 |

| 400 | 177 |

| 450 | 175 |

| 500 | 174 |

| 525 | 172 |

Imperial units

| Temperature | Proof strength |

|---|---|

| Rp0.2 | |

| oF | ksi |

| min | |

| 210 | 31.9 |

| 300 | 30.5 |

| 390 | 29.2 |

| 480 | 28.0 |

| 570 | 27.0 |

| 660 | 26.3 |

| 750 | 25.7 |

| 840 | 25.4 |

| 930 | 25.2 |

| 975 | 24.9 |

Physical properties

Density: 8.1 g/cm3, 0.30 lb/in3

Metric units, Imperial units

| Temperature, °C | W/(kg oC) | Temperature, °F | Btu/(ft h oF) |

|---|---|---|---|

| 20 | 11 | 68 | 6 |

| Temperature, °C | J/(kg °C) | Temperature, °F | Btu/(lb °F) |

|---|---|---|---|

| 20 | 440 | 68 | 0.11 |

| Temperature, °C | Per °C | Temperature, °F | Per °F |

|---|---|---|---|

| 30-100 | 14.2 | 86-200 | 7.9 |

| 30-200 | 14.6 | 86-400 | 8.1 |

| 30-300 | 14.9 | 86-600 | 8.3 |

| 30-400 | 15.1 | 86-800 | 8.4 |

| 30-500 | 15.3 | 86-1000 | 8.5 |

1) Mean values in temperature ranges (x10-6)

Welding

The weldability of Sanicro® 41 is good. Suitable methods of fusion welding are manual metal-arc welding (MMA/SMAW) and gas-shielded arc welding, with the TIG/GTAW method as first choice.

Since the material has low thermal conductivity and high thermal expansion. Welding plans should therefore be carefully selected in advance, so that distortions of the welded joint are minimized. If residual stresses are a concern, solution annealing can be performed after welding.

For Sanicro® 41, heat-input of <1.0 kJ/mm and interpass temperature of <100°C (210°F) are recommended. A string bead welding technique should be used.

Recommended filler metals for temperature

TIG/GTAW or MIG/GMAW welding

ISO 18274 S Ni 8065/AWS A5.14 ERNiFeCr-1 (e.g. Exaton Sanicro® 41 Cu)

ISO 14343 S 27 31 4 Cu L/AWS A5.9 ER383 (e.g. Exaton 27.31.4.LCu)

MMA/SMAW welding

ISO 14172 E Ni 8025, E Ni 8165

ISO 3581 E 27 31 4 Cu L R/AWS A5.4 E383-16 (e.g. Exaton 27.31.4.LCuR)

Overlay welding

ISO 18274 S Ni 8065/AWS A5.14 ERNiFeCr-1 (e.g. Exaton Sanicro® 41 Cu) wire or strip electrodes are recommended for overlay welding of tube sheets and high-pressure vessels in cases where corrosion resistance, equal to that of Sanicro® 41, is required.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.