Sanicro® 30 is a low-carbon version of Alloy 800 austenitic nickel-iron-chromium alloy. The grade is used for steam generator tubing in nuclear stations (PWR) and other heat exchangers for temperature up to about 550°C (1020°F) where good resistance to stress corrosion cracking (SCC) and intergranular corrosion is required.

Standards

- UNS: N08800

- EN Number: 1.4558

- EN Name: X2NiCrAlTi32-20

- W.Nr.: 1.4558

- DIN: X 2 NiCrAlTi 32 20

- BS: NA15

Product standards

Seamless condenser and heat exchanger tubes: ASTM A213, B163, EN 10216-5

Seamless tube and pipe: ASTM A312, B407, EN 10216-5

Approvals

Approved for use according to ASME Boiler and Pressure Vessel Code Section III, division 1 and Section VIII, division 1 and 2

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Cu | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| ≤0.030 | 0.5 | 0.6 | ≤0.020 | ≤0.015 | 20 | 32 | ≤0.10 | 0.5 | 0.3 |

Fe=Bal.

The Co content is normally max 0.10%. Subject to agreement, material with a lower Co content can be supplied.

Corrosion resistance

General corrosion

Sanicro® 30 has approximately the same resistance to organic and inorganic acids as steel of the ASTM TP 304 type. Its resistance to sodium hydroxide is very good except at the very highest concentrations and temperatures.

Pitting

The material has somewhat better resistance to pitting than steel of the ASTM TP 304 type.

Intergranular corrosion and stress corrosion cracking

In comparison with the standard Alloy 800, Sanicro® 30 has improved resistance both to intergranular corrosion and to intergranular stress corrosion cracking. This is obtained by a high degree of stabilization and a production sequence giving a small grain size. The resistance to trans- granular stress corrosion cracking is very good as for all high-nickel alloys.

Gas corrosion

In general this grade is not used at temperatures high enough for gas corrosion to be a problem. For such cases the appropriate metal to choose is Sanicro® 31HT. However, compared with Sanicro® 31HT, Sanicro® 30 has about the same resistance to gas corrosion.

Bending

Heat treatment after cold bending is not normally necessary, but this point must be decided with regard to the degree of bending and the operating conditions. Heat treatment, if any, should take the form of stress relieving or solution annealing.

Hot bending is carried out at 1050-850°C (1920-1560°F) and should be followed by solution annealing.

Forms of supply-finishes and dimensions

Seamless tube and pipe

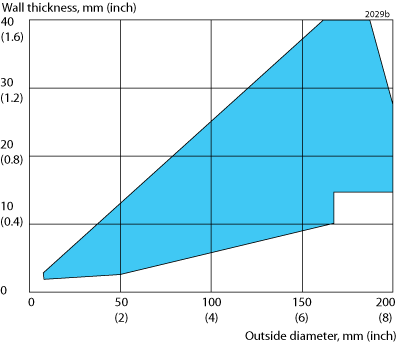

Tube and pipe are supplied hot- or cold-worked, solution-annealed and white-pickled or bright-annealed. The principal size range can be seen from Fig. 1, but also certain sizes can be delivered on request.

Figure 1. Principal size range for seamless tube and pipe.

Figure 1. Principal size range for seamless tube and pipe.

Heat treatment

The tubes are delivered in heat treated condition. If another treatment is needed after further processing the following is recommended.

Stress relieving

800-875°C (1470-1605°F), 10-15 minutes, cooling in air

Solution annealing

950-1050°C (1740-1920°F), 1-10 minutes, rapid cooling in water or air.

Mechanical properties

The figures below refer to cold-worked and annealed sizes up to 10 mm (3/8") wall thickness. For larger sizes and other finishes values are given on request.

For heat exchangers tubes, higher yield strength according to ASME Code Case N 20 can be applied. Slightly cold worked condition refers to outside diameter below 30 mm (1.2")

At 20°C (68°F)

Annealed condition

| Yield strength | Tensile strength | Elong. | Hardness Vickers | |

|---|---|---|---|---|

| 0.2% offset | 1.0% offset | 2" | ||

| MPa | MPa | MPa | % | |

| approx. | ||||

| ≥207 | ≥210 | 520-689 | ≥30 | 150 |

1 MPa = 1 N/mm2

| Yield strength | Tensile strength | Elong. | Hardness Vickers | |

|---|---|---|---|---|

| 0.2% offset | 1.0% offset | 2" | ||

| ksi | ksi | ksi | % | |

| approx. | ||||

| ≥30 | ≥31 | 75-100 | ≥30 | 150 |

Slightly cold-worked condition (O.D. max. 30 mm; 1.2")

| Yield strength | Tensile strength | Elong. | Hardness Vickers | |

|---|---|---|---|---|

| 0.2% offset | 1.0% offset | 2" | ||

| MPa | MPa | MPa | % | |

| approx. | ||||

| ≥335 | ≥355 | 570-700 | ≥30 | 170 |

| Yield strength | Tensile strength | Elong. | Hardness Vickers | |

|---|---|---|---|---|

| 0.2% offset | 1.0% offset | 2" | ||

| ksi | ksi | ksi | % | |

| approx. | ||||

| ≥48.5 | ≥51.5 | 82-102 | ≥30 | 170 |

At higher temperatures

Annealed condition

| Temperature | Yield strength | |

|---|---|---|

| °C | 0.2% offset | 1.0% offset |

| MPa | MPa | |

| min. | min. | |

| 100 | 190 | 215 |

| 200 | 175 | 195 |

| 300 | 165 | 185 |

| 400 | 160 | 180 |

| 500 | 150 | 170 |

| 600 | 145 | 165 |

| Temperature | Yield strength | |

|---|---|---|

| °F | 0.2% offset | 1.0% offset |

| ksi | ksi | |

| min. | min. | |

| 200 | 28 | 31.5 |

| 400 | 25.5 | 28 |

| 600 | 24 | 26.5 |

| 800 | 23 | 25.5 |

| 1000 | 21.5 | 24.5 |

| 1100 | 21 | 24 |

Slightly cold-worked condition

| Temperature | Yield strength | |

|---|---|---|

| °C | 0.2% offset | 1.0% offset |

| MPa | MPa | |

| min. | min. | |

| 100 | 325 | 335 |

| 200 | 310 | 320 |

| 300 | 300 | 310 |

| 400 | 290 | 300 |

| 500 | 280 | 290 |

| 600 | 275 | 285 |

| Temperature | Yield strength | |

|---|---|---|

| °F | 0.2% offset | 1.0% offset |

| ksi | ksi | |

| min. | min. | |

| 200 | 47.5 | 48.5 |

| 400 | 45 | 46 |

| 600 | 43.5 | 44.5 |

| 800 | 41.5 | 43 |

| 1000 | 40.5 | 42 |

| 1100 | 40 | 41.5 |

Physical properties

Density: 8.0 g/cm3; 0.29 lb/in3

Scaling temperature in air: 1150°C, 2100°F

| Temperature, °C | W/(m °C) | Temperature, °F | Btu/(ft h °F) |

|---|---|---|---|

| 20 | 12 | 68 | 7 |

| 100 | 14 | 200 | 8 |

| 200 | 16 | 400 | 9 |

| 300 | 17 | 600 | 10 |

| 400 | 18 | 800 | 11 |

| 500 | 20 | 1000 | 12 |

| 600 | 23 | 1100 | 13 |

| Temperature, °C | W/(m °C) | Temperature, °F | Btu/(ft h °F) |

|---|---|---|---|

| 20 | 475 | 68 | 0.11 |

| 100 | 500 | 200 | 0.12 |

| 200 | 515 | 400 | 0.12 |

| 300 | 525 | 600 | 0.13 |

| 400 | 525 | 800 | 0.13 |

| 500 | 535 | 1000 | 0.13 |

| 600 | 585 | 1100 | 0.14 |

1) Mean values

| Temperature, °C | μΩm | Temperature, °F | μΩin. |

|---|---|---|---|

| 20 | 0.99 | 68 | 39 |

| 100 | 1.01 | 200 | 39.5 |

| 200 | 1.03 | 400 | 40.5 |

| 300 | 1.05 | 600 | 41.5 |

| 400 | 1.08 | 800 | 43 |

| 500 | 1.12 | 1000 | 45 |

| 600 | 1.18 | 1100 | 46 |

| Temperature, °C | Per °C | Temperature, °F | Per °F |

|---|---|---|---|

| 20-100 | 16 | 68-200 | 9 |

| 20-200 | 16 | 68-400 | 9 |

| 20-300 | 16 | 68-600 | 9 |

| 20-400 | 16.5 | 68-800 | 9 |

| 20-500 | 16.5 | 68-1000 | 9 |

| 20-600 | 17 | 68-1100 | 9.5 |

1) Mean values (x10-6)

| Temperature, °C | MPa | Temperature, °F | ksi |

|---|---|---|---|

| 20 | 200 | 68 | 29.0 |

| 400 | 175 | 600 | 26.1 |

| 600 | 160 | 1100 | 23.4 |

1) (x103)

Welding

The weldability of Sanicro® 30 is good. Suitable methods of fusion welding are manual metal-arc welding (MMA/SMAW) and gas-shielded arc welding, with the TIG/GTAW method as first choice.

Since the material has low thermal conductivity and high thermal expansion. Welding plans should therefore be carefully selected in advance, so that distortions of the welded joint are minimized. If residual stresses are a concern, solution annealing can be performed after welding.

For Sanicro® 30, heat-input of <1.0 kJ/mm and interpass temperature of <100°C (210°F) are recommended. A string bead welding technique should be used.

Recommended filler metals for temperature

TIG/GTAW or MIG/GMAW welding

ISO 18274 S Ni 6082/AWS A5.14 ERNiCr-3 (e.g. Exaton Ni72HP)

MMA/SMAW welding

ISO 14172 E Ni 6182/AWS A5.11 ENiCrFe-3 (e.g. Exaton Ni71)

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.