Alleima® Zr 702 is a zirconium grade characterized by immunity to stress corrosion cracking and high resistance to pitting and crevice corrosion. The grade has very good corrosion resistance in most organic acids, excellent corrosion resistance in mineral acids, good corrosion resistance in strong alkalis and moderate mechanical strength.

Alleima® Zr 702 main characteristics:

- High heat transfer efficiency

- Very low thermal expansion

- Immunity to stress corrosion cracking (SCC).

- High resistance to localized (pitting and crevice) forms of corrosion

- Very good corrosion resistance in most organic acids

- Exceptional corrosion resistance in mineral acids

- Good corrosion resistance in strong alkalis

Alleima® Zr 702 is used in environments where even the best stainless steels are not sufficiently corrosion resistant. Zirconium is in many cases the ideal choice from both technical and economical point of view (the price/life time relation).

Standards

- UNS: R 60702

Product standards

ASTM B523 or equivalent

Approvals

ASME SB- 523

Vd TÜV Werkstoffblatt 480 (plate specification)

Other specifications on request.

Chemical composition (nominal)

| Zr+Hf | Hf | Fe+Cr | H | N | C | O |

|---|---|---|---|---|---|---|

| ≥99.2 | ≤4.5 | ≤0.2 | ≤0.005 | ≤0.025 | ≤0.05 | ≤0.16 |

Applications

Zirconium 702 tubing is resistant in most organic acids and mineral acids. Typical applications for seamless zirconium tubing are as heat exchangers, coolers, condensers and piping systems in the production of urea, acetic acid, formic acid, nitric acid and methyl methacrylate.

Corrosion resistance

Zirconium is immune to SCC (Stress Corrosion Cracking) and has very good corrosion resistance in, for example, the following environments.

- Dry chlorine gas

- Bromine and iodine gas

- Hydrochloric acid, all concentrations up to boiling temperature

- Nitric acid, all concentrations up to boiling temperature

- Sulphuric acid up to 70% concentration at boiling temperature

- Phosphoric acid up to 60% concentration at boiling temperature

- Most organic acids (e.g. acetic, formic), all concentrations up to boiling temperature

- Salt melts

- Metal melts

Detailed corrosion data on zirconium 702 in various environments taken from the open literature will be provided on request.

Fabrication

Bending

Zirconium tubing can be bent at room temperature using standard bend tooling and techniques. When bending thin walled tubing or if a tight bend radius is needed, a mandrel should be used for adequate support of the ID. The mandrel should be well lubricated in order to prevent galling of the ID surface. Due to moderate strength and low elastic modulus of this alloy, springback is greater than that of stainless steel and must be taken into account.

Machining and cutting

Machining and cutting zirconium tubing is routine when the following procedures are used:

- Use low cutting speeds and high feed rates

- Use large volumes of coolant

- Use sharp tools and replace as soon as worn

- Never stop feeding while tool is in contact with workpiece

Forms of supply

Product sizes and type

Tube and pipe are supplied in the cold reduced and annealed or partially annealed condition. Tubing can be delivered in the following surface conditions: mill finish, acid etched, or belt polished. Seamless zirconium tubing can be delivered in the following principle size range:

OD 8-40 mm

WT 0.7-3.5 mm

L up to 14.70 m

(Other dimensions can be quoted for special projects.)

Due to manufacturing limitations OD/WT ratios over 25 can only be quoted under certain circumstances.

Mechanical properties

Tensile properties at 20°C for Alleima® Zr 702, as specified by ASTM B 523, are shown below.

| Yield strength* | Tensile strength | Elongation | ||

|---|---|---|---|---|

| Rp0.2 | Rm | |||

| MPa | ksi | MPa | ksi | A2" |

| % | ||||

| ≥205 | ≥30 | ≥380 | ≥55 | 16 |

*RP0.2 corresponds to 0.2% offset yield strength.

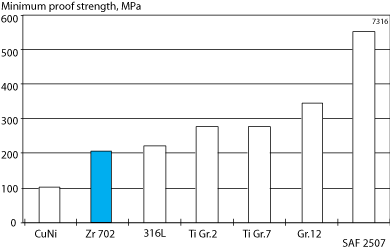

A comparison of the yield strength of Alleima® Zr 702 with other corrosion resistant tubing alloys is shown in figure 1.

Figure 1 Yield strength vs. tubing material.

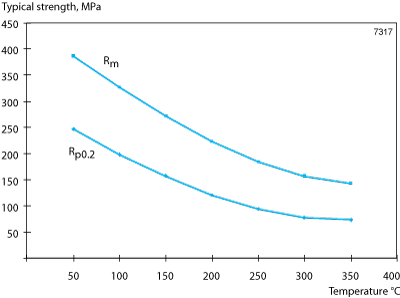

At high temperatures

The strength of Alleima® Zr 702 at high temperatures is shown in figure 2.

Figure 2 Typical yield and tensile strength of Alleima® Zr 702 vs. temperature.

Physical properties

Density: 6.5g/cm3

Melting point: 1852°C

Thermal conductivity: 22 W/(m °C)

Elastic bending modulus: 99.3 GPa

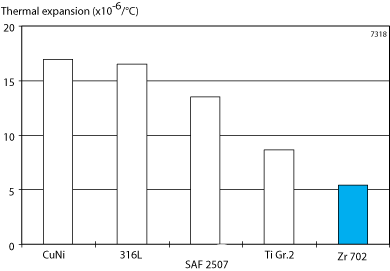

Thermal expansion: 5.4x10-6 /°C

The coefficient of thermal expansion for zirconium 702, in comparison to other corrosion resistant tubing alloys, is shown in figure 3.

Figure 3 Thermal expansion vs. material.

Welding

The weldability of Alleima® Zr 702 is good. Suitable method of fusion welding is gas tungsten arc welding GTAW/TIG with or without filler material. Due to the reactive nature of zirconium, inert gas such as pure argon must be used as both shielding gas and backing gas.

The welding of Alleima® Zr 702 calls for special cleanness. Joint surface and filler material should be cleaned with a suitable solvent, e.g. acetone and free from grease, dirt, chalk and other impurities.

Recommended filler material

GTAW/TIG

AWS A5.24 ERZr2

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.