Alleima® Ti Grade 2 is a Commercially Pure (CP) titanium seamless tubing characterized by:

- Excellent resistance to general corrosion in seawater

- Resistant to stress corrosion cracking in chloride and sour gas environments

- Excellent resistance to pitting, crevice, and erosion corrosion

- High heat transfer efficiency

- Good formability and weldability

- Very low thermal expansion

- Moderate strength

Standards

- ASTM: Grade 2

- UNS: R50400

Chemical composition (nominal)

| N | H | O | Fe | C |

|---|---|---|---|---|

| ≤0.03 | ≤0.015 | ≤0.25 | 0.30 | 0.08 |

Applications

Commercially Pure Ti Grade 2 titanium tubing provides excellent service in aggressive chloride-containing environments. The excellent mechanical, physical, and corrosion resistance properties of this grade make it an economical choice for many applications by reducing the product life cycle costs of equipment. Typical applications include:

Oil and gas industry

Chloride environments such as seawater handling and process systems and hydraulic and process fluid tubes in umbilicals.

Seawater cooling

Tubing for heat exchangers and coolers on oil platforms, in refineries, chemical industries, process industries, and other industries using seawater or chlorinated seawater as coolant.

Refineries and petrochemical plants

Heat exchangers and condensers where the process environment contains chlorides, sulfides, organics, organic acids, nitric acid, or wet chlorine.

Geothermal wells

Heat exchangers in geothermal exploitation units, systems exposed to geothermal or high-salinity brines, tubing, and casing for production.

Pulp and paper industry

Tubing for chloride-containing bleaching environments.

Desalination plants

Tube and pipe for seawater transport, heat exchanger tubing, and pressure vessels for reverse osmosis units.

Corrosion resistance

Titanium should not be used with strong reducing acids, fluoride solutions, pure oxygen, or anhydrous chlorine.

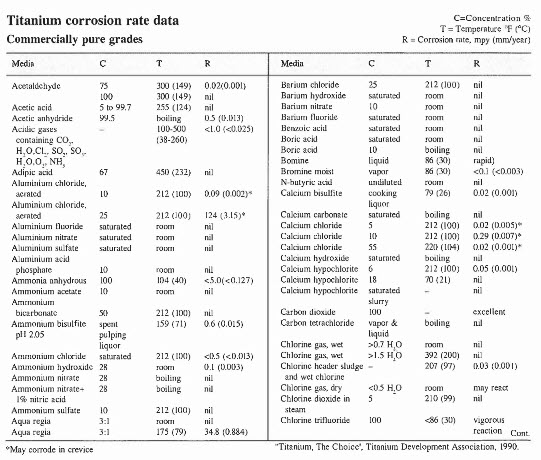

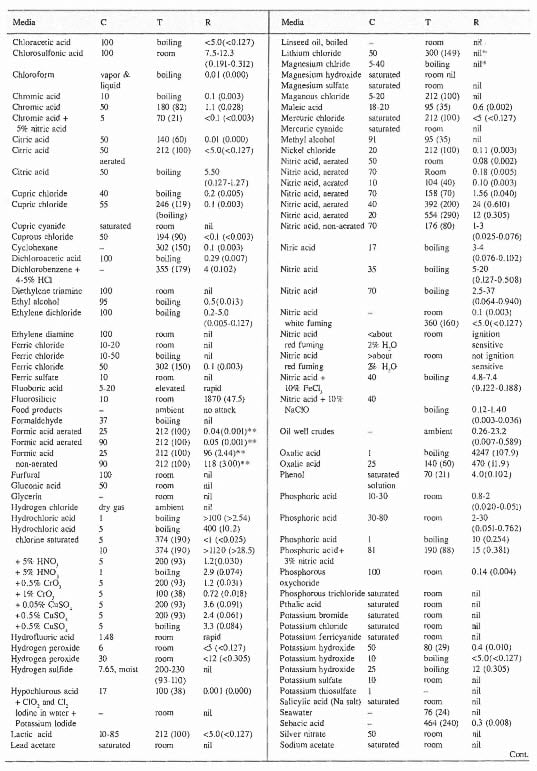

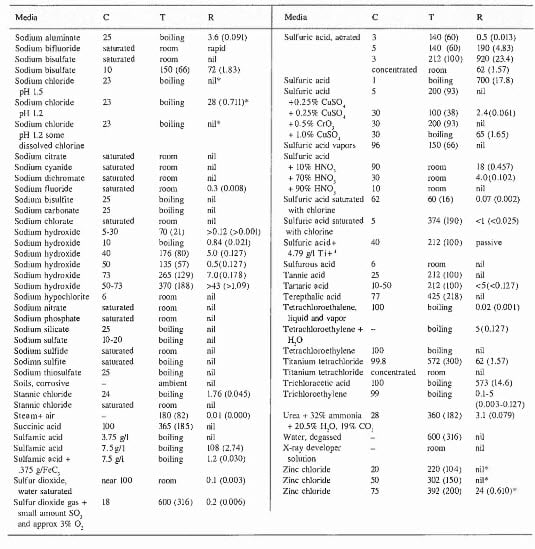

General corrosion

The general corrosion rates for Grade 2 titanium in a variety of media are shown in Table 1. CP titanium exhibits good corrosion resistance to a wide variety of environments including:

- Seawater and brines

- Inorganic salts

- Moist chlorine gas

- Alkaline solutions

- Oxidizing acids

- Organics and organic acids

- Sulfur compounds

Crevice corrosion

CP titanium exhibits good resistance to crevice corrosion in salt solutions compared to stainless steels. CP titanium will not exhibit crevice corrosion at temperatures under 80 °C ( 176°F) regardless of pH, even under super chlorinated conditions.

Stress corrosion cracking

Grade 2 titanium shows excellent resistance to stress corrosion (SCC) cracking in hot chloride solutions and is immune to sec in seawater.

Erosion corrosion

Titanium shows excellent resistance to erosion in flowing

seawater with velocities up to 130 ft/sec ( 40 m/sec) showing negligible effect on the material. The presence of abrasive particles, such as sand, has only a small effect on corrosion.

Hydrogen embrittlement

There is no significant absorption of hydrogen into titanium exposed to seawater, even at higher temperatures. Normally hydrogen absorption occurs only when the three following conditions are met:

- pH is < 3 or > 12

- Temperature is above l 76F (80C)

- A mechanism exists for hydrogen generation such as a galvanic couple or impressed current.

Bio-corrosion

Titanium alloys have demonstrated a unique immunity to all forms of microbiologically influenced corrosion. Since titanium alloys do not display any toxicity toward marine organisms, biofouling can occur in seawater. This can be minimized by chlorination or by increasing the water velocity through the heat exchanger.

Corrosion fatigue

Titanium, unlike many other materials, does not show a decrease in fatigue performance in the presence of seawater. Both fatigue endurance limits and fatigue crack growth rates are the same whether tested in air or seawater.

Galvanic corrosion

In the galvanic series, titanium is towards the noble end near stainless steels, and will normally act as the cathode when coupled with other metals. The titanium will therefore not be affected by galvanic corrosion but can accelerate corrosion of the other metal. Coupling of titanium with more noble metals, such as graphite, only enhances titanium's passivity.

Fabrication

Bending

Titanium tubing can be bent at room temperature using standard bend tooling and techniques. When bending thin walled tubing or if a tight bend radius is needed, a mandrel should be used for adequate support of the ID. The mandrel should be well lubricated in order to prevent galling of the ID surface. Due to the moderate strength and low modulus of this alloy, springback is about twice that of stainless steel and must be taken into account.

Roller expansion

Titanium tubing can be roller expanded into tube sheets similar to other tubing materials. The suggested wall reduction for titanium is 10% to provide optimum pull out strength.

Machining and cutting

Machining and cutting titanium tubing is routine when the following procedures are used:

- Use low cutting speeds and high feed rates

- Use large volumes of coolant

- Use sharp tools and replace as soon as worn

- Never stop feeding while tool is in contact with workpiece

Tubing and pipe specifications

ASTM B337: Seamless and welded pipe

ASTM B338: Seamless and welded tubing

ASME SB338: Seamless and welded tubing

AMS 4943: Aerospace hydraulic tubing, annealed

AMS 4944/4945: Aerospace hydraulic tubing, cold worked and stress relieved

DIN/VD/TUV 230/2: Seamless tube and pipe

Approved by the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code, Section VIII, Div. 1, Case 2081

Sizes and surface conditions

Tube and pipe are supplied in the cold reduced or cold reduced and annealed condition. Tubing can be delivered in the following surface conditions: as cold pilgered, acid etched, or belt polished. The principal size range for seamless products is shown as the white area in figure 1.

Figure 1 Principal size range for seamless tube and pipe.

| OD | WT | L |

| 9.50 - 24.4 mm | .07 - 4 mm | up to 17 m |

Other dimensions can be quoted for special projects.

Mechanical properties

Tensile properties for Grade 2 titanium, as specified by ASTM B338, shown below:

| Ultimate Strength | Yield strength | Elongation 2" | |||

| ksi | MPa | ksi | MPa | % | |

| Min | 50 | 345 | 40 | 275 | 20 |

| Max | 65 | 450 | 10 | ||

| Typical data | 530 | 380 | 39 | ||

A comparison of the yield strength of CP Titanium Grade 2 with other corrosion resistant tubing alloys is shown in figure 3. *Min. 400 MPa for Titanium 2H

Hardness

92 HRB max.

Physical properties

Density 0.162 lbs/in3, 4.51 g/cm3

CP titanium tubing is lighter than comparable steel products, as its density is 45% less than ferrous alloys. Light weight and moderate strength give this product advantages where a strength-to-weight ratio better than stainless steel or CuNi alloys is required.

Melting point

3020°F ( l 660°C)

Beta transus

1675F (913C)

Thermal Conductivity

22 W/m'C (12.7 BTU) för RT

(Timet: 12,6 resp. 21,8. BPVC: 22-19.9 RT-200'C.)

Elastic modulus

The elastic modulus of Cp titanium, as shown below, is roughly one-half that of steel alloys.

| psi | GPa | |

| Tension (E) | 15.0 x 106 | 103 |

Fatigue performance

Titanium, unlike many other materials, does not show a decrease in fatigue performance in the presence of seawater. Both fatigue endurance limits and fatigue crack growth rates are the same whether tested in air or seawater.

Weldability

The weldability of CP titanium tubing is very good as long as the necessary precautions are taken. Due to the reactive nature of titanium inert gas shielding must be in place on both the OD and ID of the tubes. The material must be also

free from any grease or oil contamination.

Manual or automatic TIG welding is regularly used to weld titanium tubing either with or without filler wire. A low heat input should be used to minimize the size of the heat-affected zone. No post-weld heat treatment is normally performed on

titanium tubing.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.