Alleima® SX is a high silicon containing austenitic stainless steel developed for use in concentrated sulfuric acid. The grade is characterized by:

- Excellent corrosion resistance in concentrated sulfuric acid

- Excellent corrosion resistance in high concentrated nitric acid

- Good mechanical properties and ductility

- Good weldability

- Product standards

- ASTM A213, A312, and A479

Approvals

- Approved by the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code, Section VIII, div. 1 construction

Standards

- UNS: S32615

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

|---|---|---|---|---|---|---|---|---|

| ≤0.025 | 5.0 | 0.5 | ≤0.045 | ≤0.030 | 17.5 | 19.5 | 0.4 | 2.0 |

Applications

Alleima® SX is particularly suitable for use in the following applications:

- Acid coolers

- Acid piping systems

- Acid distributors

- Acid towers and tanks

- Pumps, nozzles, internals, strainers, mesh pads etc.

Corrosion resistance

General corrosion

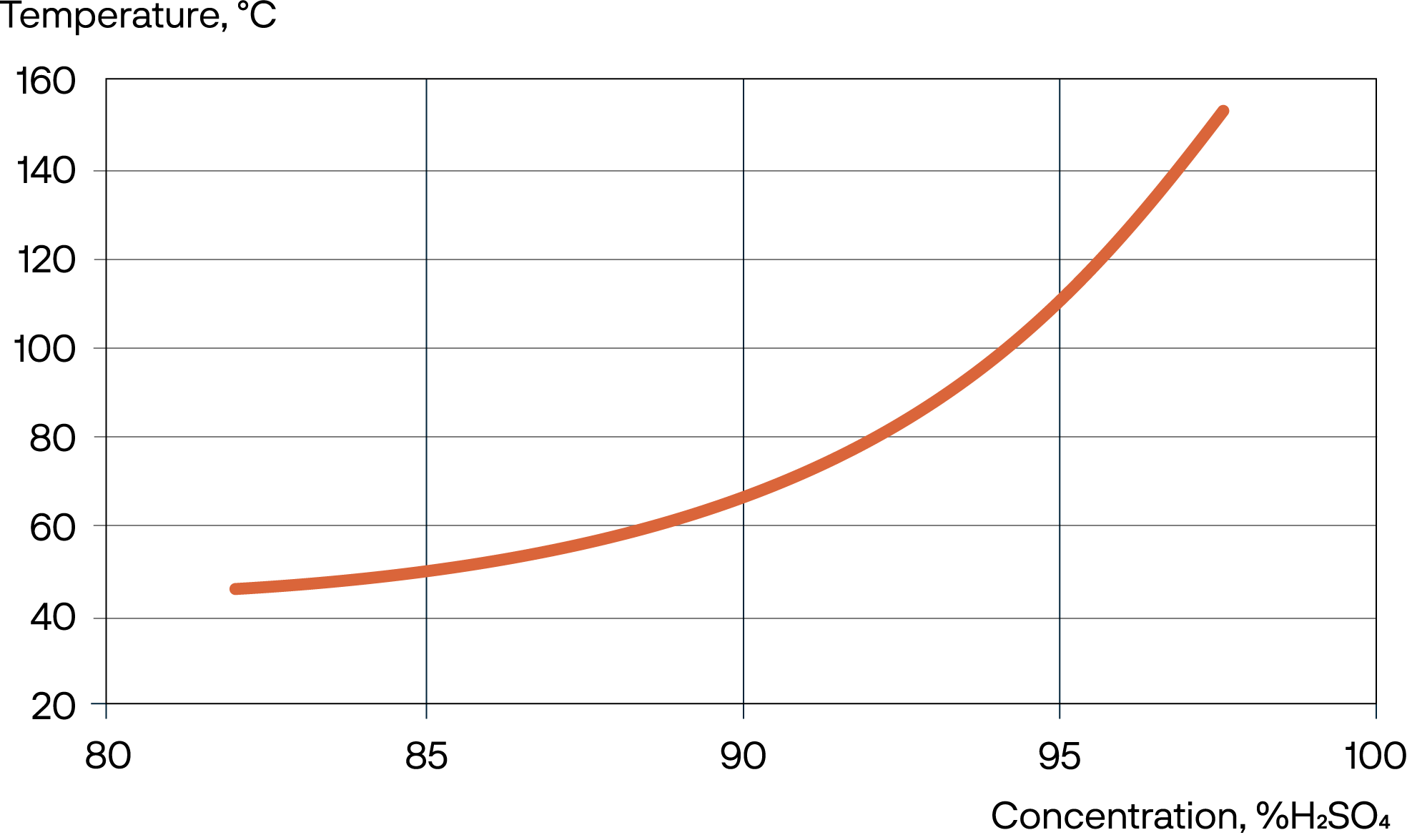

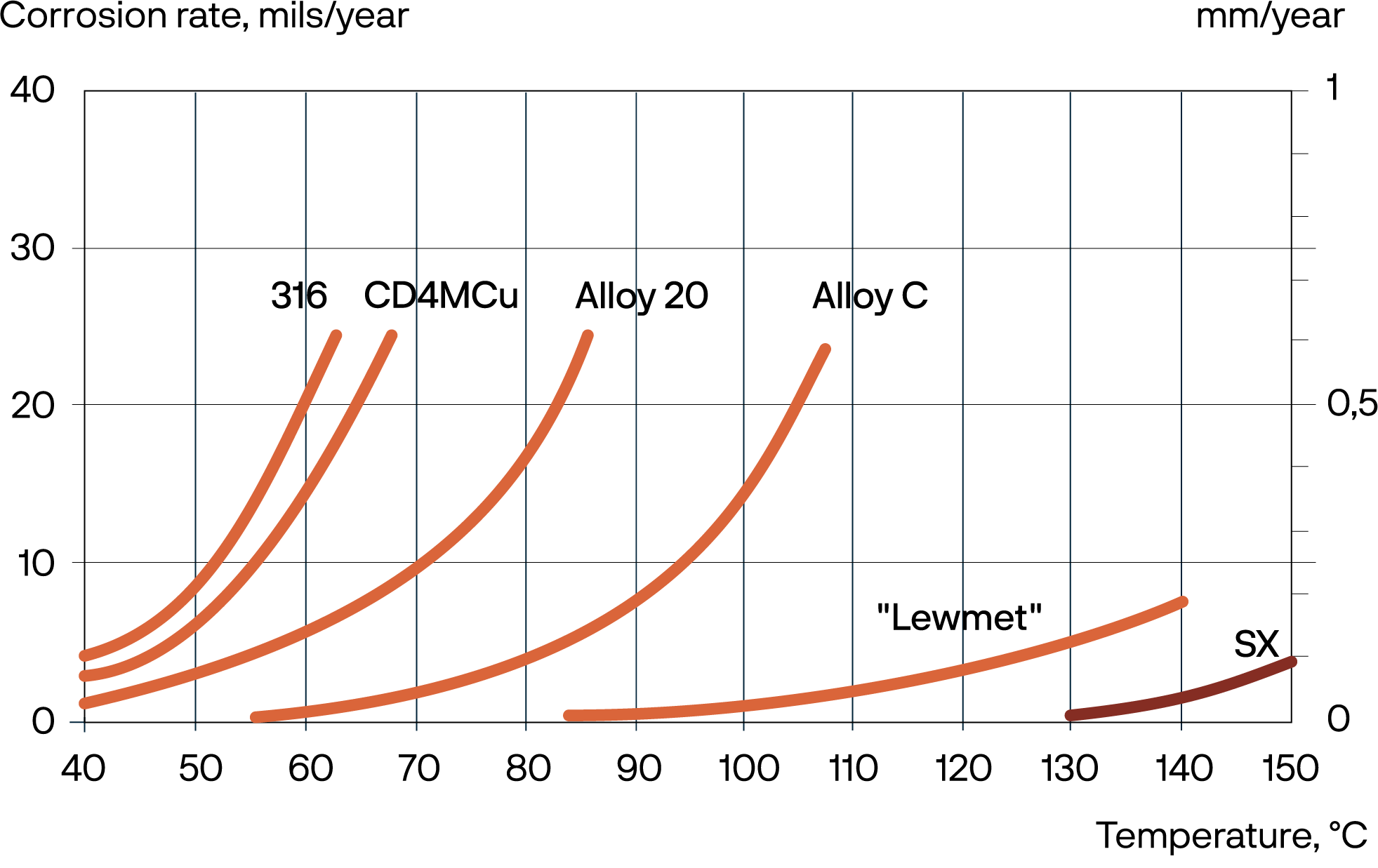

Alleima® SX has excellent corrosion resistance in concentrated sulfuric acid, both in static and dynamic conditions. This is illustrated by the isocorrosion diagram, Figure 1, and by the comparative test data for different alloys, Figure 2.

Figure 1. Isocorrosion diagram, 0.1 mm/year, for Alleima® SX in concentrated sulfuric acid at static conditions.

Figure 2. Approximate corrosion rate curves for various alloys in 98% H2SO4 at static conditions.

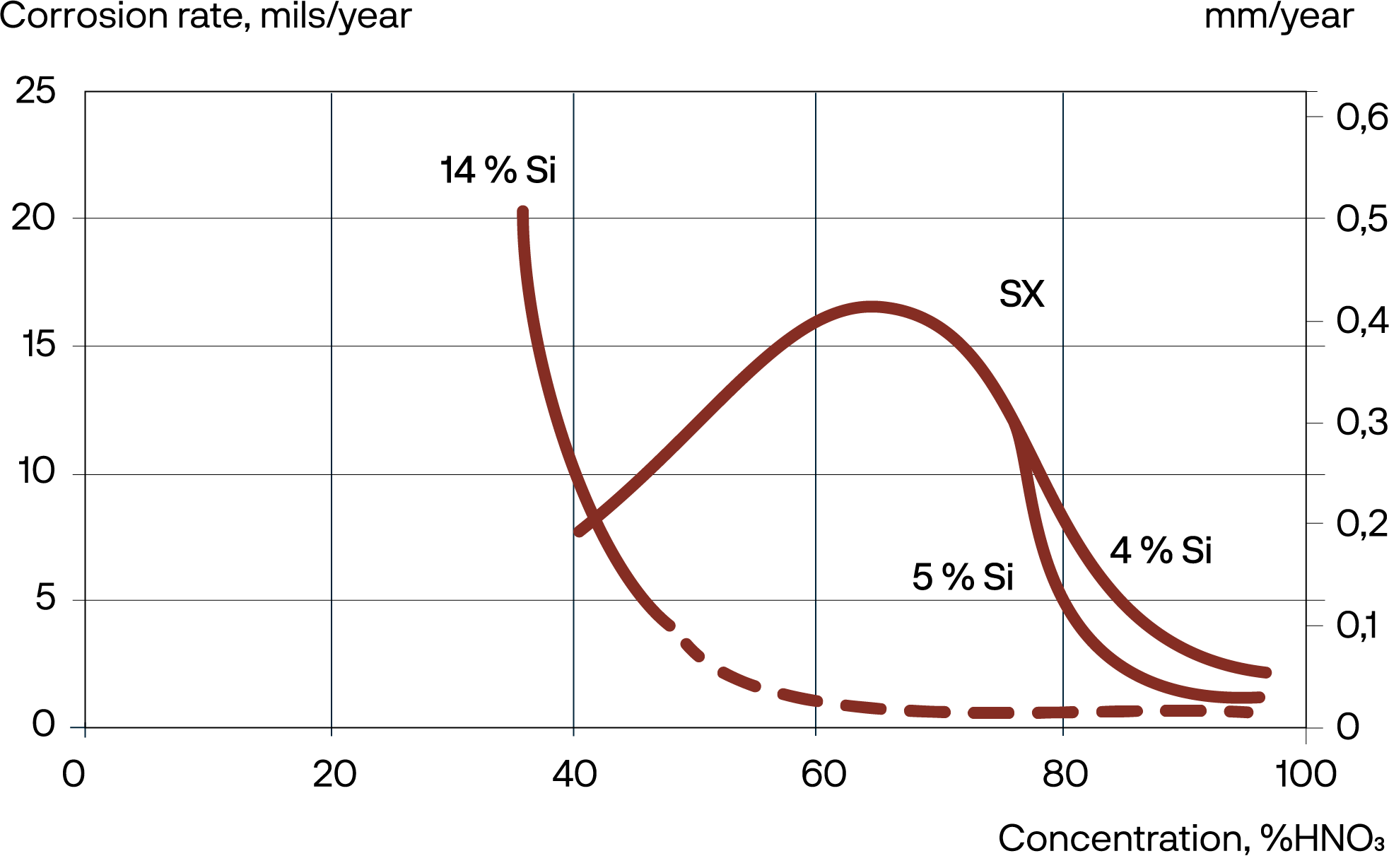

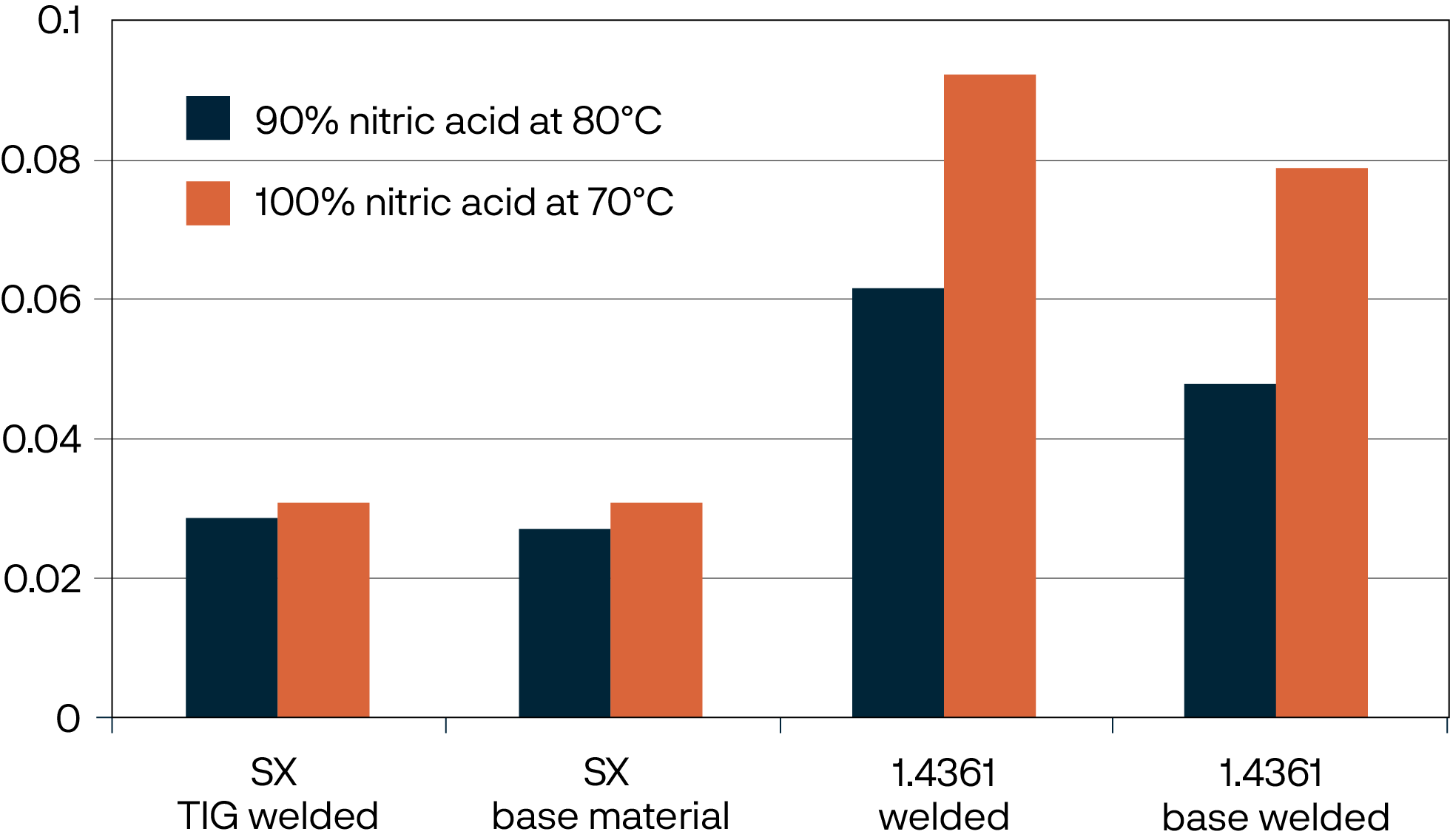

Alleima® SX has excellent corrosion resistance in high concentrated nitric acid. The material has been tested with good results in both 90 and 100% nitric acid. The corrosion properties in nitric acid can be seen in the isocorrosion diagram in Figure 3, and in the corrosion rate diagram in Figure 4.

Figure 3. Effect of silicon content in Fe-Cr-Ni alloys on corrosion resistance in HNO3.

Figure 4. Results from tests in 90% and 100% HNO3 at 80°C and 70°C respectively.

Pitting and crevice corrosion

The steel may be sensitive to pitting and crevice corrosion even in solutions of relatively low chloride content. Alleima® SX is used in acid coolers with demi-water or chloride containing cooling water. The corrosivity of the cooling water needs to be evaluated in every particular case taking different factors, such as metal temperature, pH, and chlorination practice into account.

Stress corrosion and cracking

Austenitic steels are susceptible to stress corrosion cracking (SCC). This may occur at temperatures above 60°C (140°F) if the steel is subjected to tensile stresses and at the same time comes into contact with certain solutions, particularly those containing chlorides. Such service conditions should therefore be avoided. Conditions when plants are shut down must also be considered, as the condensates which are then formed can develop conditions that lead to both SCC and pitting.

Forms of supply

Seamless tube and pipe in Alleima® SX is available in the solution-annealed and white-pickled condition or as solution annealed by a bright-annealing process. Solution annealed bar is also available.

Mechanical properties

| Proof strength | Tensile strength | Elong. | Hardness | |

|---|---|---|---|---|

| Rp0.2a | Rp1.0a | Rm | A2" | HRB |

| MPa | MPa | MPa | % | |

| ≥220 | ≥250 | ≥550 | ≥25 | ≤90 |

| Proof strength | Tensile strength | Elong. | Hardness | |

|---|---|---|---|---|

| Rp0.2a | Rp1.0a | Rm | A2" | HRB |

| ksi | ksi | ksi | % | |

| ≥32 | ≥36 | ≥80 | ≥25 | ≤90 |

1 MPa = 1 N/mm2

a) Rp0.2 and Rp1.0 correspond to 0.2% offset and 1.0% offset yield strength, respectively.

b) Based on L0 = 5.65 √S0 where L0 is the original gauge length and S0 the original cross-sectional area.

At high temperatures

| Temperature | Proof strength |

|---|---|

| °C | Rp0.2 |

| MPa | |

| 50 | ≥205 |

| 100 | ≥180 |

| 150 | ≥170 |

| 200 | ≥160 |

| Temperature | Proof strength |

|---|---|

| °F | Rp0.2 |

| ksi | |

| 100 | ≥32 |

| 200 | ≥26.4 |

| 300 | ≥24.8 |

| 400 | ≥23.1 |

Impact strength

Due to its austenitic microstructure, Alleima® SX has very good impact strength, both at room temperature and at cryogenic temperatures.

Physical properties

Density: 7.9 g/cm3, 0.28 lb/in3

| Temperature, °C | J/kg °C | Temperature, °F | Btu/lb °F |

|---|---|---|---|

| 50-100 | 500 | 122-212 | 0.12 |

| Temperature, °C | 20 | 100 | 200 |

|---|---|---|---|

| W/m °C | |||

| Alleima® SX | 11 | 13 | 14 |

| ASTM 304L | 15 | 16 | 18 |

| Temperature, °F | 68 | 200 | 400 |

|---|---|---|---|

| Btu/(ft h °F) | |||

| Alleima® SX | 6.5 | 7.5 | 8.0 |

| ASTM 304L | 8.5 | 9.5 | 10.5 |

| Temperature, °C | 30-100 | 30-200 | 30-300 |

|---|---|---|---|

| Per °C | |||

| Alleima® SX | 15.0 | 15.5 | 16.0 |

| Carbon steel | 12.5 | 13.0 | 13.5 |

| ASTM 304L | 16.5 | 17.0 | 17.5 |

| Temperature, °F | 86-200 | 86-400 | 86-600 |

|---|---|---|---|

| Per °F | |||

| Alleima® SX | 8.5 | 8.5 | 9.0 |

| Carbon steel | 7.0 | 7.0 | 7.5 |

| ASTM 304L | 9.5 | 9.5 | 10.0 |

1) Mean values in temperature ranges (x10-6)

| Temperature, °C | MPa | Temperature, °F | ksi |

|---|---|---|---|

| 20 | 200 | 68 | 29.0 |

| 400 | 170 | 752 | 24.7 |

1) (x103)

Welding

The weldability of Alleima® SX is good. Welding must be carried out without preheating, and normally there is no need for any subsequent heat treatment. Suitable method of fusion welding is gas tungsten arc welding GTAW/TIG.

For Alleima® SX, heat-input of <1.0 kJ/mm and interpass temperature of <50°C (120°F) are recommended. A string bead welding technique should be used.

Recommended filler metals

GTAW/TIG

EN ISO 14343-A: W Z 18 13 Si Cu L (e.g. Exaton SX)

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.