Alleima® 316LVM is a vacuum remelted, molybdenum alloyed, austenitic stainless steel.

The grade is characterized by:

- High strength

- High fatigue strength

- Excellent microcleanliness

- Excellent structural homogeneity

- High surface finish

Standards

- UNS: S31673

- DIN: X 2 CrNiMo 18 15 3

Product standards

- Bar and wire: ASTM F138

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N |

|---|---|---|---|---|---|---|---|---|---|

| ≤0.025 | 0.6 | 1.7 | ≤0.025 | ≤0.003 | 17.5 | 14 | 2.8 | ≤0.10 | ≤0.10 |

Applications

Alleima® 316LVM is used for implant applications; hip stems, femoral heads, spinal systems, acetabular cups, intramedullary nails, bone screws, knee joints, and pins, bone and nail plates, internal fixation devices, dental implants, staples.

This grade is also used for cardiovascular applications: guide wires, cardiac stents and for surgical instruments and tools; blood lancets, stylets, trocars.

Corrosion resistance

Alleima® 316LVM has very good resistance in physiological environments to:

- General and intergranular corrosion due to high purity and low ferrite content

- Pitting and crevice corrosion due to the high molybdenum content

Alleima® 316LVM is capable of passing the Moneypenny Strauss intergranular corrosion test, in accordance with ISO / ASTM requirements.

Forms of supply

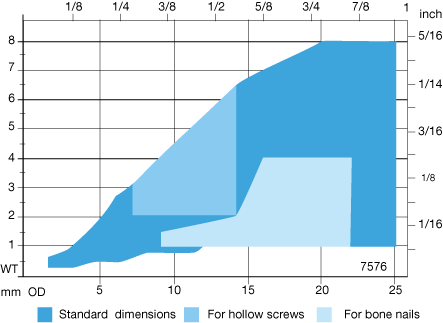

Tubes, thick wall

Bright annealed or cold drawn

OD 6.0-25.4 mm (0.236-1 in.)

Wall thickness 2.6-8 mm (0.102-0.315 in.)

Dimension range for thick wall tubes (larger sizes can be offered on request)

Tubes, thin wall

Extremely polished or bright surface

OD 0.50-20 mm (0.019-0.787 in.)

Wall thickness 0.1-2 mm (0.0039- 0.078 in.)

Tolerances

Thickness tolerance: +/- 10%

OD tolerance: +/- 0.75% with a minimum of +/-0.02 mm

Roughness

OD > 5mm Ra (outside) < 0.4 (by polishing)

ID > 3.2mm Ra (inside) < 0.4 - depending on thickness/diameter ratio

Specific roughness can be supplied on request, internal cleaning cannot be carried out on inside diameters below 4 mm.

All products are supplied either in the annealed or cold worked condition to provide mechanical properties as required.

Other product forms

Alleima 316LVM can also be supplied as bar (round or flat), wire and profiles (shaped wire).

Mechanical properties

| Product form | Condition | Tensile strength | Proof strength | Elongation, A | Hardness, Brinell | ||

|---|---|---|---|---|---|---|---|

| Rm | Rp0.2 | ||||||

| MPa | ksi | MPa | ksi | % |

|||

| min | min | min | min | typical | typical | ||

| Bar, Wire | Annealed | 490 | 71 | 190 | 28 | 45 | 160 |

| Bar, Wire | Medium tensile | 900 | 131 | 700 | 101 | 15 | 285 |

| Bar, Wire | High tensile | 1100 | 160 | 800 | 116 | 12 | 300 |

| Bar, Wire | Extra high tensile | 1400 | 203 | ||||

| Tube, thick wall | Bright annealed | 515-690 | 75-100 | 220 | 32 | min 45 | 155-210 |

| Tube, thick wall | Cold finished | 860-1100 | 125-160 | 690 | 100 | min 12 | 260-330 |

| Profile | Cold rolled | 860-1100 | 125-160 | 690 | 100 | 12 | 260-330 |

| Tube , thin wall Tube, thin wall |

Annealed Cold worked |

490-690 860-1100 |

71-100 125-160 |

190 690 |

28 100 |

40 12 |

|

Note that extra high tensile strength can be achieved for diameter ≤ 5 mm

Physical properties

| Property | ||

|---|---|---|

| Density ( 20 °C) | 8.0 g/cm3 | 0.29 lb/in3 |

| Modulus of elasticity, x103 (20°C) | 200 MPa | 29.0ksi |

| Specific heat capacity (20°C) | 485 J/(kg °C) | 0.11Btu/(lb °F) |

| Thermal conductivity (20°C) | 14W /(m °C) | 8 Btu/(ft h °F) |

| Thermal expansion, x10-6 (30-100°C) | 16.5 per °C | 9.5 per °F |

Machining

| Hardness | Cutting speed range | Feed range | |||

|---|---|---|---|---|---|

| SFM | m/min | IPR | mm/rev | ||

| Turning | 160-300 | 900-145 | 275-45 | 0.002-0.024 | 0.05-0.6 |

| Milling | 160-300 | 870-165 | 265-50 | 0.002-0.016 | 0.05-0.4 |

| Drilling | 160-300 | 115-195 | 35-60 | 0.002-0.012 | 0.05-0.3 |

Disclaimer: Alleima is not providing any products or services that are intended or may be construed to be recommending or otherwise advising on, in any manner, the design, suitability, appropriateness or effectiveness, from a medical/biological/safety perspective, of any medical material, instrument and/or medical device.