Alleima® 2RE69 is a fully austenitic stainless steel with extra low carbon and impurity contents. The grade is characterized by:

- Excellent resistance to corrosion in ammonium carbamate and nitric acid

- Excellent resistance to intergranular corrosion

- High resistance to pitting and crevice corrosion

- Good weldability

Alleima® 2RE69 has been developed primarily to cope with the severe corrosive conditions existing in the urea industry. The longest service life is so far 35 years, which confirms the optimal properties for the grade Alleima® 2RE69 in urea strippers.

Standards

- UNS: S31050

- EN Number: 1.4466

- EN Name: X1CrNiMoN25-22-2

- W.Nr.: 1.4466* 1), 1.4465* 2)

- DIN: X 2 CrNiMo 25 22 2* 1), X 1/CrNiMoN 25 25 2* 2)

- AFNOR: Z 1 CND25.22AZ

* Obsolete. Replaced by EN.

1) Appearing in TÜV Wien-Werkstoffblatt 093

2) Appearing in SEW400

Urea specifications issued by:

- Stamicarbon

- Saipem

- Kellogg

- Urea Casale

Product standards

- ASTM A213, A312

- EN 10216-5

- SEW 400

Approvals

- Approved by the American Society of Mechanical Engineers (ASME) for use in accordance with ASME Boiler and Pressure Vessel Code, Section VIII, Divisions 1 and 2

- ASME Code Case 2038-5 for forgings

- TÜV Wien-Werkstoffblatt 093

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Mo | N |

|---|---|---|---|---|---|---|---|---|

| ≤0.020 | ≤0.4 | 1.7 | ≤0.015 | ≤0.010 | 25 | 22 | 2.1 | 0.12 |

Applications

Alleima® 2RE69 is used successfully in all critical high-pressure units of modern urea processes, such as:

| Stripper tubes | Stamicarbon, Montedison IDR |

| Outer layer of bimetallic ( stripper tubes) | Saipem |

| Ferrules | All processes |

| Carbamate condensers | All processes |

| Decomposers | Montedison |

| Reactor coils | UTI |

Alleima 2RE69 has also found extensive use in other corrosive environments in fertilizer plants, such as:

- Nitric acid cooler/condensers cooled with polluted cooling water

- Heating coils and pipe in NPK plants – Norsk Hydro process

Corrosion resistance

General corrosion

Alleima® 2RE69 was originally developed for stripper tubes used in the production of urea. Practical experience has confirmed its excellent corrosion resistance in urea/carbamate solutions at high pressures and temperatures.

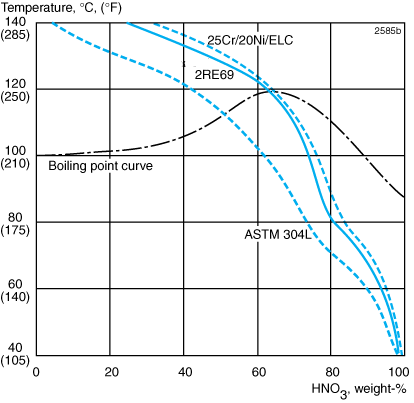

Alleima® 2RE69 is also highly resistant to inorganic acids, as illustrated by the iso-corrosion diagram for nitric acid, Figure 1.

Figure 1. Iso-corrosion diagram for Alleima® 2RE69, Alleima® 2RE10 (25 Cr/20Ni/ELC) and ASTM 304L in natural aerated nitric acid. The curves represent a corrosion rate of o.1 mm/year (4 mpy).

Figure 1. Iso-corrosion diagram for Alleima® 2RE69, Alleima® 2RE10 (25 Cr/20Ni/ELC) and ASTM 304L in natural aerated nitric acid. The curves represent a corrosion rate of o.1 mm/year (4 mpy).

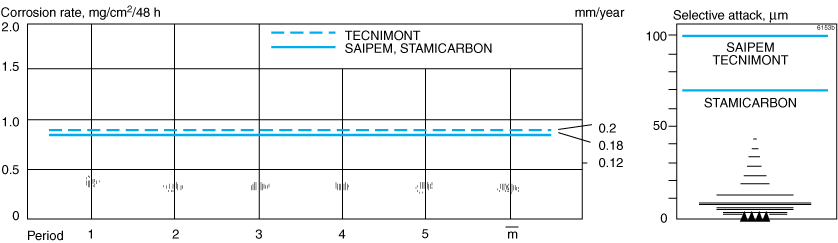

Figure 2. Statistical evaluation of Huey tests for Alleima® 2RE69. As can be seen from the figure to the right, the selective attack values for Alleima® 2RE69 are typically below 10 microns (μm), i.e. well below licensors' maximum values.

Figure 2. Statistical evaluation of Huey tests for Alleima® 2RE69. As can be seen from the figure to the right, the selective attack values for Alleima® 2RE69 are typically below 10 microns (μm), i.e. well below licensors' maximum values.

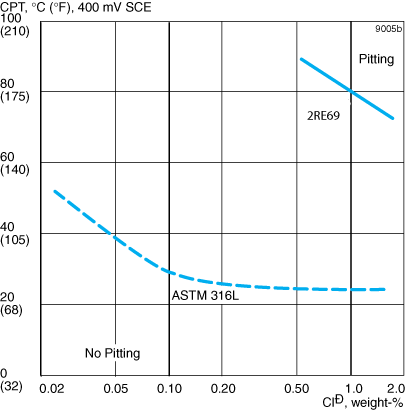

Figure 3. Critical pitting temperature (CPT) for Alleima® 2RE69 and ASTM 316L in neutral chloride solutions (potentiostatic determination at +400mV SCE).

Figure 3. Critical pitting temperature (CPT) for Alleima® 2RE69 and ASTM 316L in neutral chloride solutions (potentiostatic determination at +400mV SCE).

Intergranular corrosion

Alleima® 2RE69 is highly resistant to intergranular corrosion after welding. Huey test values for TIG welded specimens are typically below 0.12 mm/year for unsensitized material (4.8 mpy, 0.66 μm/48 h).

A statistical evaluation of Huey tests, as specified in the urea specifications, is shown in Figure 2. A maximum value of 0.12 mm/year (4.8 mpy,

0.66 μm/48 h) can be guaranteed for straight Alleima® 2RE69 tubes in the 'as delivered' condition. Max. 20 μm (8 mils) selective attack is similarly guaranteed.

Pitting and crevice corrosion

Alleima® 2RE69 has very good resistance to pitting, as illustrated in Figure 3, and is also far more resistant to crevice corrosion than ASTM 316L.

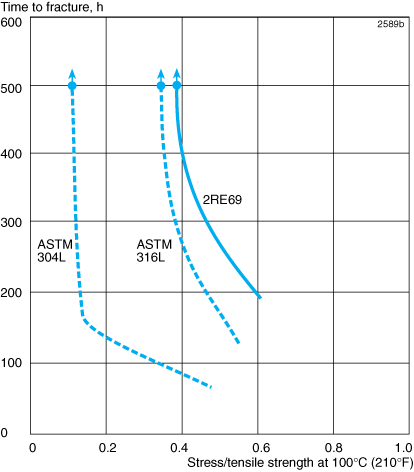

Stress corrosion cracking (SCC)

Conventional austenitic stainless steels of type ASTM 304 and 316 are susceptible to stress corrosion cracking (SCC) in chloride-bearing solutions at temperatures exceeding about 60°C (140°F). The higher nickel content makes Alleima® 2RE69 slightly more resistant, as assessed in laboratory tests, see Figure 4.

Figure 4. Results of SCC tests on Alleima® 2RE69, ASTM 316L and 304L in aerated 40% CaCl2 at 100C (210F).

Figure 4. Results of SCC tests on Alleima® 2RE69, ASTM 316L and 304L in aerated 40% CaCl2 at 100C (210F).

Erosion corrosion

The good mechanical strength of Alleima® 2RE69 makes it resistant to erosion-corrosion. Ferrules for urea strippers are one application where this property is utilized.

Fabrication

Bending

The excellent formability of Alleima® 2RE69 permits cold bending to small bending radii. Annealing is not normally necessary after cold bending. Heat treatment, if any, should take the form of solution annealing, see under 'Heat treatment'.

Hot bending is carried out at 1100–850°C (2010–1560°F), usually without subsequent heat treatment.

Expanding

Alleima® 2RE69 tubes can be expanded into tube sheets in the same way as tubes of austenitic stainless steel of type ASTM 316L.

Machining

The chip removing machining of stainless steels always requires an adjustment of cutting data and machining method to give satisfactory results. When turning is undertaken with carbide tipped tools, the cutting speed should be reduced by 30% for finish machining and 60% for rough machining compared with the cutting speeds applied for ASTM 316L. Much the same applies to other operations. If high speed steel tools are used, the cutting speed should be reduced by 20 % compared with the cutting speeds applied for ASTM 316L.

Alleima can provide detailed recommendations for the choice of tools and cutting data. Data to be selected as for grade Sanmac 316/316L, taking into account the above comments.

Forms of supply

Alleima® 2RE69 seamless tube and pipe is supplied in dimensions up to 355 mm (14.0 in.) outside diameter in the solution annealed and white pickled condition, or solution annealed by a bright annealing process. U-tubes can be supplied on request.

Other forms of supply

- Urea high-pressure pipe fittings and flanges

- Bar steel

- Plate and sheet

Heat treatment

If heat treatment is needed after further processing the following is recommended.

Solution annealing

1070–1120°C (1960–2050°F), 5–15 minutes, depending on size, followed by rapid cooling in water or air.

Mechanical properties

The strength values stated refer to tube and pipe. Lower values may apply to bar, plate, sheet and forgings.

| Proof strength | Tensile strength | Elong. | ||

|---|---|---|---|---|

| Rp0.2a) | Rp1.0a) | Rm | Ab) | A2" |

| MPa | MPa | MPa | % | % |

| ≥270 | ≥300 | 580–780c) | ≥30c) | ≥25 |

1 MPa = 1 N/mm2

| Proof strength | Tensile strength | Elong. | ||

|---|---|---|---|---|

| Rp0.2a) | Rp1.0a) | Rm | Ab) | A2" |

| MPa | MPa | MPa | % | % |

| ≥39 | ≥43 | 84–113c) | ≥30c) | ≥25 |

a) Rp0.2 and Rp1.0 correspond to 0.2% offset and 1.0% offset yield strength, respectively.

b) Based on L0 = 5.65 ÖS0 where L0 is the original gauge length and S0 the original cross-sectional area.

c) Requirements according to EN 1.4466, W.-Nr. 1.4465 and AFNOR can be fulfilled on request.

Impact strength

Due to its austenitic microstructure, Alleima® 2RE69 has very good impact strength both at room temperature and at cryogenic temperatures.

Tests have demonstrated that the steel fulfils the requirements of European standards EN 13445-2 (UFPV-2) ( (min. 60 J (44 ft-lb) at -270oC (-455oF) ) and

EN 10216-5 (min. 60 J (44 ft-lb) at -196oC (-320oF) ).

Hardness (HRB): max. 95

At high temperatures

| Temperature | Proof strength | Tensile strength | |

|---|---|---|---|

| °C | Rp0.2 | Rp1.0 | Rm |

| MPa | MPa | MPa | |

| min. | min. | min. | |

| 50 | 250 | 285 | 555 |

| 100 | 230 | 260 | 530 |

| 150 | 215 | 245 | 510 |

| 200 | 200 | 230 | 500 |

| 250 | 190 | 215 | 490 |

| 300 | 175 | 205 | 480 |

| 350 | 165 | 195 | 470 |

| 400 | 155 | 185 | 460 |

| 450 | 145 | 175 | 455 |

| 500 | 140 | 170 | 450 |

| Temperature | Proof strength | Tensile strength | |

|---|---|---|---|

| °F | Rp0.2 | Rp1.0 | Rm |

| ksi | ksi | ksi | |

| min. | min. | min. | |

| 200 | 33.5 | 38 | 77.5 |

| 400 | 29 | 33 | 72.5 |

| 600 | 25 | 39 | 69 |

| 800 | 21.5 | 26 | 66.5 |

| 900 | 20.5 | 25 | 65.5 |

Physical properties

Density: 7.9 g/cm3, 0.29 lb/in3

Relative magnetic permeability

at 6400–55700 A/m: 1.003

| Temperature, °C | W/m °C | Temperature, °F | Btu/ft h °F |

|---|---|---|---|

| 20 | 13 | 68 | 7.5 |

| 100 | 15 | 200 | 8.5 |

| 200 | 17 | 400 | 9.5 |

| 300 | 19 | 600 | 11 |

| 400 | 21 | 800 | 12.5 |

| 500 | 23 | 1000 | 13.5 |

| 600 | 25 | 1200 | 14.5 |

| 700 | 26 | 1300 | 15 |

| Temperature, °C | J/kg °C | Temperature, °F | Btu/lb °F |

|---|---|---|---|

| 20 | 485 | 68 | 0.12 |

| 100 | 505 | 200 | 0.12 |

| 200 | 540 | 400 | 0.13 |

| 300 | 565 | 600 | 0.14 |

| 400 | 585 | 800 | 0.14 |

| 500 | 605 | 1000 | 0.15 |

| 600 | 615 | 1200 | 0.15 |

| 700 | 625 | 1300 | 0.15 |

| Temperature, °C | Per °C | Temperature, °F | Per °F |

|---|---|---|---|

| 30–100 | 15.5 | 86–200 | 8.5 |

| 30–200 | 16 | 86–400 | 9 |

| 30–300 | 16.5 | 86–600 | 9 |

| 30–400 | 17 | 86–800 | 9.5 |

| 30–500 | 17 | 86–1000 | 9.5 |

| 30–600 | 17 | 86–1200 | 9.5 |

| 30–700 | 17.5 | 86–1400 | 10 |

| Temperature, °C | MPa | Temperature, °F | ksi |

|---|---|---|---|

| 20 | 195 | 68 | 28.3 |

| 100 | 190 | 200 | 27.6 |

| 200 | 182 | 400 | 26.3 |

| 300 | 174 | 600 | 25.1 |

| 400 | 166 | 800 | 23.8 |

| 500 | 158 | 1000 | 22.5 |

Welding

The weldability of Alleima® 2RE69 is good. Welding must be carried out without preheating, and normally there is no need for any subsequent heat treatment. Suitable methods of fusion welding are manual metal-arc welding (MMA/SMAW) and gas-shielded arc welding, with the TIG/GTAW method as first choice.

In common with all fully austenitic stainless steels, Alleima® 2RE69 has low thermal conductivity and high thermal expansion. Welding plans should therefore be carefully selected in advance, so that distortions of the welded joint are minimized. If residual stresses are a concern, solution annealing can be performed after welding.

For Alleima® 2RE69, heat-input of <1.0 kJ/mm and interpass temperature of <100°C (210°F) are recommended. A string bead welding technique should be used.

Recommended filler metals

TIG/GTAW or MIG/GMAW welding

ISO 14343 S 25 22 2 N L (e.g. Exaton 25.22.2.LMn)

MMA/SMAW welding

ISO 3581 E 25 22 2 N L B (e.g. Exaton 25.22.2.LMnB)

ISO 14343 S 25 22 2 N L wire or strip electrodes are recommended for overlay welding of tube sheets and high-pressure vessels in cases where corrosion resistance, equal to that of Alleima® 2RE69, is required.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.