Alleima® 13C26 is a martensitic stainless chromium steel supplied in strip form. The grade is mainly supplied in annealed or cold rolled condition, characterized by:

- Soft delivery condition

- Good formability

- Good blanking properties

After heat treatment, Alleima® 13C26 is characterized by:

- High hardness

- Good corrosion resistance

- High wear resistance

Standards

- DIN: X65Cr13

Product standards

ISO 7153-1

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr |

|---|---|---|---|---|---|

| 0.68 | 0.4 | 0.7 | ≤0.025 | ≤0.010 | 13 |

Applications

Alleima® 13C26 is mainly used for ophthalmologic and surgical surgical blades. It is also a standard grade for razor blades and used for different types of knives.

Forms of supply

The strip can be supplied either in coils or as straightened lengths of 0.5 - 4.0 meter (1.6 - 13.1 feet). The coil weight is max 5 kg/mm (280 lb/in.) of strip width.

Hardening and tempering of the strip steel is required to achieve the correct finish and to meet the properties necessary for the end user.

| Thickness | Width | ||

|---|---|---|---|

| mm (in.) | mm (in.) | ||

| min. | max. | min. | max. |

| 0.1 (0.0039) | 1.0 (0.039) | 5 (0.197) | 350 (13.78) |

Other sizes can be supplied to meet specific requirements.

Tolerances

The thickness and width tolerances are +/- tolerances to the nominal size. The normal tolerance classes for most of our strip products are T2 and B1. Tighter tolerances as well as other tolerance limits can be offered upon request.

Heat treatment

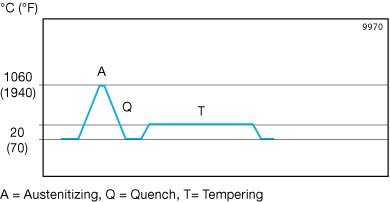

Hardening data and Tempering data: Piece hardening

Austenitizing

Belt furnace. Time in furnace according to table

| Thickness | Thickness | Time |

|---|---|---|

| mm | in. | minutes |

| 2.5 | 0.100 | 5 |

| 3.0 | 0.118 | 6 |

| 3.25 | 0.128 | 7 |

| 3.5 | 0.138 | 8 |

| 3.45 | 0.148 | 10 |

| 4 | 0.157 | 12 |

Quench

As rapid as possible, for optimal result 600°C (1110°F) should be reached within 2 minutes or less.

| Hardness | Temperature |

|---|---|

| HRC | °C (°F) |

| 59 | 175 (345) |

| 57 | 225 (435) |

| 55 | 350 (660) |

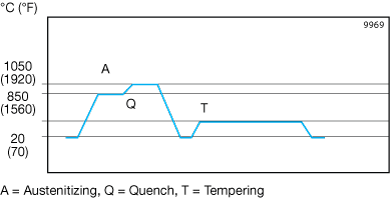

Hardening data and Tempering data : Batch hardening

Temperature should be equalized at 850°C (1560°F) for 30 minutes to avoid unnecessary temperature variations.

Austenitizing

Batch furnace. 30 minutes in furnace.

Quench

As rapid as possible, for optimal result 600°C (1110°F) should be reached within 2 minutes or less.

| Hardness | Temperature |

|---|---|

| HRC | °C (°F) |

| 59 | 175 (345) |

| 57 | 225 (435) |

| 55 | 350 (660) |

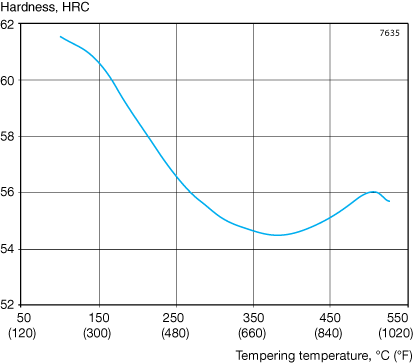

Hardness versus tempering temperature

Brittleness occurs with tempering above 450°C (840°F).

Mechanical properties

| As delivered | Tensile strength Rm | Hardness | |

|---|---|---|---|

| MPa (ksi) | HV | HRC | |

| Annealed | max. 800(116) | max. 250 | max. 22 |

| Cold rolled | 830-1050 (121-152) | 260-328 | 24-33 |

| Hardened and tempered | 1700-2000 (247-290) | 545-633 | 52-57 |

Mechanical properties can vary depending on the tempering parameters

Physical properties

The physical properties of a steel are related to a number of factors, including alloying elements, heat treatment and manufacturing route, but the data presented below can generally be used for rough calculations.

Density : 7.7 g/cm3 (0.28 lb/in.3)

Disclaimer: Alleima is not providing any products or services that are intended or may be construed to be recommending or otherwise advising on, in any manner, the design, suitability, appropriateness or effectiveness, from a medical/biological/safety perspective, of any medical material, instrument and/or medical device.