SAF™ 32760 is a high alloy super-duplex (austenitic-ferritic) stainless steel for service in highly corrosive conditions.

The grade is characterized by:

- Excellent resistance to stress corrosion cracking in chloride-bearing environments

- Excellent resistance to pitting and crevice corrosion

- High resistance to general corrosion

- Very high mechanical strength

- Physical properties that offer design advantages

- High resistance to erosion corrosion and corrosion fatigue

- Good weldability

- Excellent mechanical properties that allow for lighter constructions, more compact design and less welding

Standards

- UNS: S32760

- EN Number: 1.4501

- EN Name: X2CrNiMoCuWN25-7-4

Product standards

- EN 10088-3, (dimensions up to 160 mm)

- EN 10272

- ISO 17781

- ASTM A479, ASTM A276

- NORSOK MDS D57 Rev 5

- Suitable for manufacturing of components in accordance with ASTM A182

Approvals

- Pressure Equipment Directive (2014/68/EU)

- NORSOK M650 Ed. 4, NORSOK M630 Ed. 6

- DNV, dimensions up to 250 mm

Certificate

- Status according to EN 10 204/3.1

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Mo | N | W | Cu |

|---|---|---|---|---|---|---|---|---|---|---|

| ≤0.030 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.010 | 25.5 | 7 | 3.8 | 0.26 | 0.7 | 0.8 |

Applications

SAF™ 32760 is a super-duplex stainless steel especially designed for service in aggressive chloride-containing environments. Some typical applicational areas are:

- Oil and gas industry

- Seawater cooling

- Salt evaporation industry

- Desalination plants

- Geothermal wells

- Refineries and petrochemical plants

- Mechanical components requiring high strength

- Pulp and paper industry

- Chemical processing

Corrosion resistance

General corrosion

SAF™ 32760 is highly resistant to corrosion by organic acids, e.g. formic and acetic acid. It is suitable for use at high concentrations and temperatures, where austenitic stainless steels corrode at a high rate.

Resistance to inorganic acids is comparable to that of high alloy austenitic stainless steels in certain concentration ranges.

Pitting and crevice corrosion

The pitting and crevice corrosion resistance of a stainless steel is primarily determined by the content of chromium, molybdenum and nitrogen. An index for comparing the resistance to pitting and crevice corrosion is the PRE number (Pitting Resistance Equivalent).

The PRE is defined as, in weight-% PRE = %Cr + 3.3x%Mo +16x%N

For duplex stainless steels the pitting corrosion resistance is dependent on the PRE-value in both the ferrite phase and the austenite phase, so that the phase with the lowest PRE-value will be limiting for the actual pitting corrosion resistance.

The minimum PRE-value for SAF™ 32760 is 40. This is significantly higher than e.g. the PRE-values for other duplex stainless steels of the 25Cr type which are not "super-duplex". As an example UNS S31260 (25Cr3Mo0.2N) has a PRE-value of typically 38.

Stress corrosion cracking

SAF™ 32760 has excellent resistance to chloride-induced stress corrosion cracking.

Erosion corrosion and corrosion fatigue

The superior mechanical properties combined with the improved corrosion resistance of SAF™ 32760 result in excellent resistance to both erosion corrosion and corrosion fatigue compared to standard austenitic stainless steels.

Forms of supply

Finishes and dimensions

SAF™ 32760 bar steel is stocked in a large number of sizes. Round bar is supplied in solution annealed and water quenched condition. The surface is peel turned and burnished.

Lengths

Bars are delivered in random lengths of 3-7 m, depending on diameter.

Straightness

| Diameter mm |

Height of arch, mm/m Typical value |

|---|---|

| > 70 | 2 |

Tolerances, mm-sizes

| Diameter, mm | Tolerances, mm |

|---|---|

| 80-95 | -0/+1.00 |

| 100-250 | -0/+1.50 |

Surface conditions

| Surface conditions |

Ra, µm Typical value |

Size, mm dia |

|---|---|---|

| Peeled and burnished | 1 | 80-250 |

Mechanical properties

Bar steel is tested in delivery condition.

The following figures apply to material in the solution annealed and quenched condition.

More detailed information can be supplied on request.

At 20°C (68°F)

Metric units

| Proof strength | Tensile strength | Elong. | HB |

|---|---|---|---|

| Rp0.2a) | Rm | Ab) | |

| MPa | MPa | % | |

| ≥550 | 750-930 |

≥25 | ≤290 |

Imperial units

| Proof strength | Tensile strength | Elong. | Hardness |

|---|---|---|---|

| Rp0.2a) | Rm | Ab) | HB |

| ksi | ksi | % | |

| ≥80 | 109-135 | ≥25 | ≤290 |

1 MPa = 1 N/mm2

a) Rp0.2 corresponds to 0.2% offset yield strength.

b) Based on L0 = 5.65√S0 , where L0 is the original gauge length and S0 the original cross-section area.

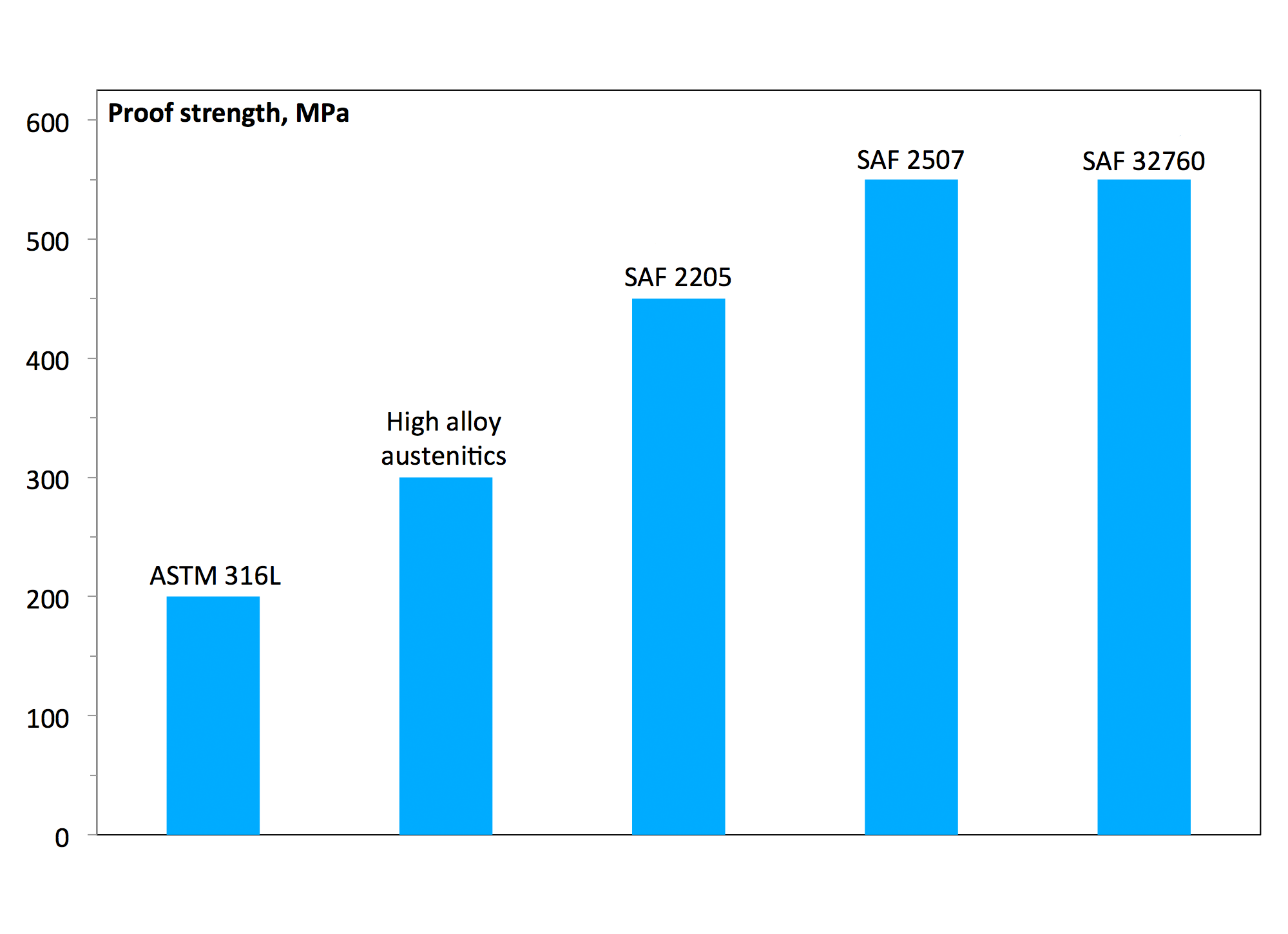

Figure 1. Comparison of proof strength.

At high temperatures

If SAF™ 32760 is exposed for prolonged periods to temperatures exceeding 250°C (480°F), the microstructure changes which results in a reduction in impact strength. This effect does not necessarily affect the behavior of the material at the operating temperature.

| Temperature, °C | Proof strength Rp0.2, MPa |

|---|---|

| min. | |

| 100 | 450 |

| 150 | 420 |

| 200 | 400 |

| 250 | 380 |

| Temperature, °F | Proof strength Rp0.2, ksi |

|---|---|

| min. | |

| 200 | 67 |

| 300 | 61 |

| 400 | 58 |

| 480 | 55 |

Impact strength

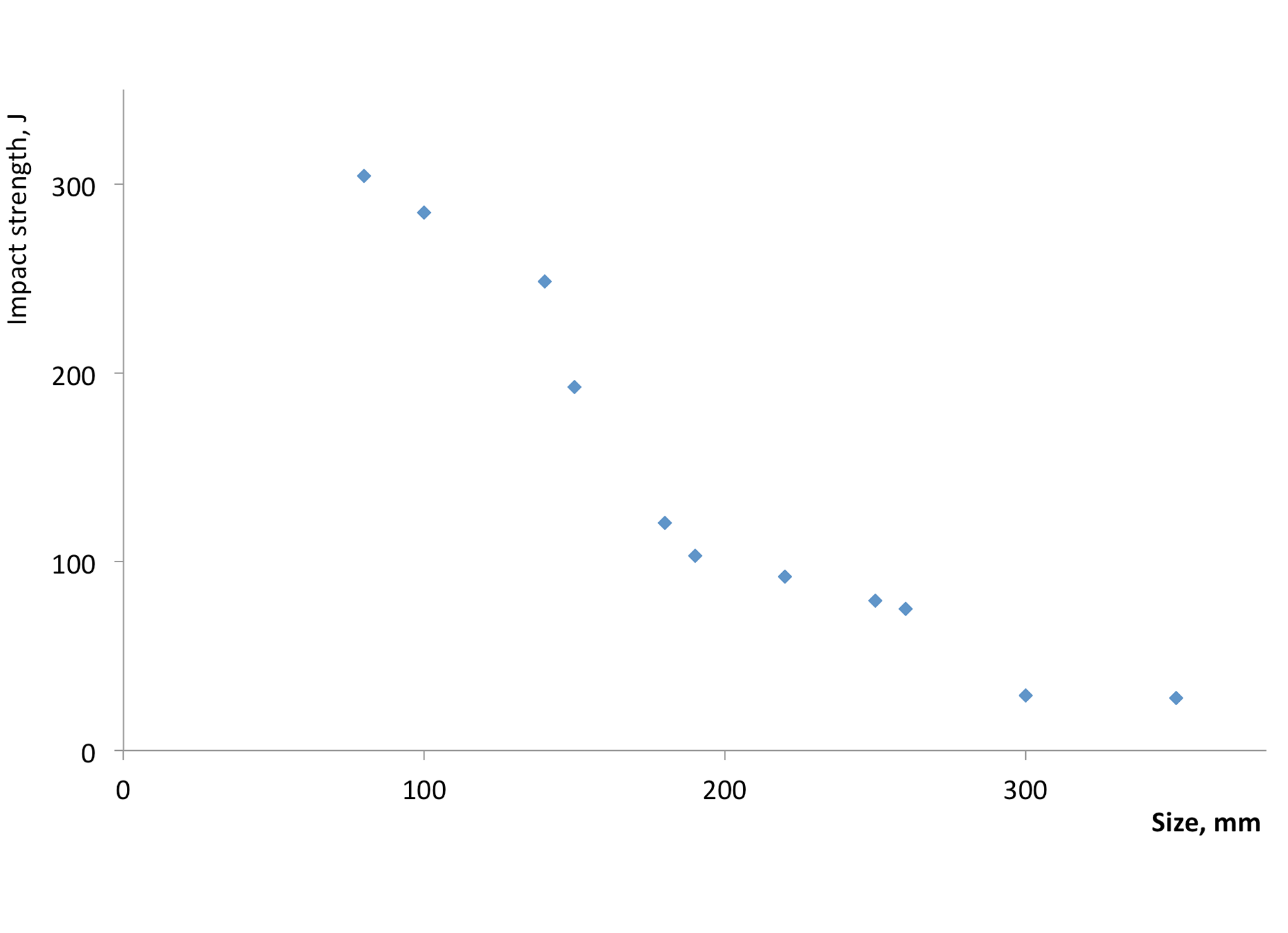

SAF™ 32760 possesses good impact strength. Figure 2 shows typical impact energy values for SAF™ 32760 in different sizes at -46°C (-50°F), using standard Charpy V specimens. Samples are taken in the longitudinal direction and the impact strength (Charpy V) at -46°C (-50°F) is min 45 J (74 ft-lb).

Figure 2. Typical impact energy values for SAF™ 32760 in different sizes at -46°C (-50°F), using standard Charpy V specimens.

Physical properties

Density

7.8 g/cm3, 0.28 lb/in3

Specific heat capacity

500 J/(kg °C) at 20°C, 0.12 Btu/(lb °F) at 68°F

Thermal conductivity

| Temperature | 20°C | 68°F |

|---|---|---|

| SAF 32760 | 15 W/(m °C) | 9 Btu/(ft h °F) |

| ASTM 316L | 14 W/(m °C) | 9 Btu/(ft h °F) |

Thermal expansion

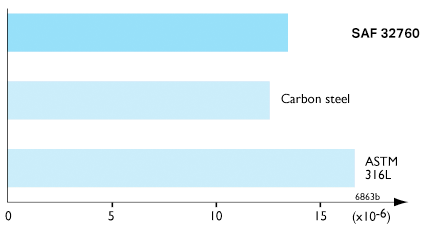

SAF™ 32760 has a coefficient of thermal expansion close to that of carbon steel. This gives SAF™ 32760 definite design advantages over austenitic stainless steels in equipment comprising both carbon steel and stainless steel. The values given below are average values in the temperature ranges.

Metric units, x10-6/°C

| Temperature, °C | 30-100 | 30-200 | 30-300 |

|---|---|---|---|

| SAF™ 32760 | 13.0 | 13.5 | 14.0 |

| Carbon Steel | 12.5 | 13.0 | 13.5 |

| ASTM 316L | 16.5 | 17.0 | 17.5 |

Imperial units, x10-6/°F

| Temperature, °F | 86-200 | 86-400 | 86-600 |

|---|---|---|---|

| SAF™ 32760 | 7.0 | 7.5 | 7.5 |

| Carbon Steel | 6.8 | 7.0 | 7.5 |

| ASTM 316L | 9.0 | 9.5 | 10.0 |

Resistivity

0.8 μΩm at 20°C, 31.5 μΩin. at 68°F

Modulus of elasticity, (x103)

Metric units; Imperial units

| Temperature, °C | MPa | Temperature, °F | ksi |

|---|---|---|---|

| 20 | 200 | 68 | 29.0 |

| 100 | 194 | 200 | 28.2 |

| 200 | 186 | 400 | 27.0 |

| 300 | 180 | 600 | 26.2 |

Machining

Being a two-phase material (austenitic-ferritic) SAF™ 32760 will present a different wear picture from that of single-phase steels of type ASTM 304L. The cutting speed must therefore be lower than that recommended for ASTM 304L. It is recommended that a tougher insert grade is used than when machining austenitic stainless steels, e.g. ASTM 304L. Also in comparison with Sanmac® 2205 lower speed and tougher insert grade is recommended. Machining recommendations available on request.

Welding

The weldability of SAF™ 32760 is good. Suitable methods of fusion welding are manual metal-arc welding (MMA/SMAW) and gas-shielded arc welding, with the TIG/GTAW method as first choice.

For SAF™ 32760, heat input of 0.2-1.5 kJ/mm and interpass temperature of <150°C (300°F) are recommended. Preheating and post-weld heat treatment is normally not necessary.

Recommended filler metals

GTAW/TIG welding

ISO 14343 S 25 9 4 N L / AWS A5.9 ER2594 (e.g. Exaton 25.10.4.L)

MMA/SMAW welding

ISO 3581 E 25 9 4 N L R / AWS A5.4 E2594-16 (e.g. Exaton 25.10.4.LR)

ISO 3581 E 25 9 4 N L B / AWS A5.4 E2594-15 (e.g. Exaton 25.10.4.LB)

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.