Alleima has been working on carbon footprint analyses, also known as Life Cycle Assessment (LCA), for selected products for an extended period. Alleima is now able to share carbon footprint data on its Rock Drill Steel (RDS) products as part of our commitment to the green transition within the mining industry.

LCA is a method for quantifying the environmental impact of products and identifying hotspots throughout the life cycle.

Committed to a sustainable future

Greenhouse gas (GHG) emissions are one of the main causes of rising climate change. The metals and mining industry accounts for approximately 4% to 7% of worldwide GHG emissions.

In 2015, the United Nations established The Paris Agreement, a legally binding climate change accord designed to mitigate climate change by capping global warming at 1.5°C above pre-industrial levels. Committing to a climate-neutral society by 2050, the EU aims to reduce GHG emissions by 50% by 2030, compared to 1990 levels, as outlined in legally binding climate goals established in 2021.

In December 2022, Alleima committed to setting science-based net zero targets in alignment with the Paris Agreement, further strengthening the already ambitious long-term net-zero targets.

Supporting the green transition in the mining industry

In response to the global shift towards sustainability and carbon footprint reduction, large companies in the mining industry are actively seeking environmentally responsible solutions. Alleima serves many clients in the drilling and mining industries, with key customers including Epiroc Drilling Tools, manufacturing rock drilling rods using rock drill steel from Alleima.

Epiroc Drilling Tools are also committed to the SBTi and have pledged to reduce their GHG emissions. By providing product specific carbon footprints, Epiroc can assess the environmental impact of their Rock Drilling Tools more accurately.

The Rock Drill Steel business for Alleima is not just about supplying steel; it's also about contributing to a more sustainable and environmentally conscious approach.

Ensuring trust by delivering reviewed carbon footprint data

To provide reliable and solid LCA data, the Alleima LCA model has been reviewed by IVL – Swedish Environmental Research Institute (IVL), which has long experience and a high level of competence within this field. IVL has also supported in the development of the data management and the development of the model as such.

IVL is an independent research institute working with applied research and consultancy to promote ecologically, economically, and socially sustainable growth in business and society at large. IVL is funded partly by the Swedish government and the Swedish business sector, and partly through appropriations granted by national and international research bodies.

This independence is essential for upholding credibility and trust, which is a key reason for Alleima selecting IVL to review their work with LCA and carbon footprint calculations.

Importance of the third-party review

In November 2023, Alleima held discussions with Michael Jansson, General Manager at Epiroc Drilling Tools, emphasizing the importance of third-party involvement.

We need to have accurate and reliable data from our suppliers to present ourselves as reliable.

For Michael Jansson, it is considered extremely valuable to have a non-profit external partner such as IVL involved.

Michael Jansson, General Manager at Epiroc Drilling Tools“We need to have accurate and reliable data from our suppliers to present ourselves as reliable. I´m afraid that there will be inflation in this matter without third-party review from an independent institute. Like Alleima, Epiroc Drilling Tools also have support from IVL in our calculations”, says Michael Jansson.

Michael Jansson, General Manager at Epiroc Drilling Tools“We need to have accurate and reliable data from our suppliers to present ourselves as reliable. I´m afraid that there will be inflation in this matter without third-party review from an independent institute. Like Alleima, Epiroc Drilling Tools also have support from IVL in our calculations”, says Michael Jansson.

Aligning to industry standards

The LCA data for RDS products has been developed in line with ISO14067 (ISO14040/ISO14044 family) which is the most common, globally accepted LCA standard. When receiving the carbon footprint, customers also receive a LCA report, describing the product, the system boundaries, the functional unit, information about the data applied, and the climate change results in different levels of aggregation for easy interpretation of the results.

Comparing carbon footprint of different manufacturers

Comparing the carbon footprint of steel from different suppliers can be challenging due to variations in calculations and reporting methods. Methods for reporting carbon footprint can vary amongst different countries and suppliers. Buyers should request the appropriate and reliable data to ensure a fair comparison.

At present, the industry lacks a standardized approach for reporting carbon footprint, but there are several ongoing initiatives to align and standardize carbon footprint methodology and the classification of green steel. The intention is to enable a comparison of suppliers. Given this situation, the current optimal choice now is to carefully select a credible third-party verifier.

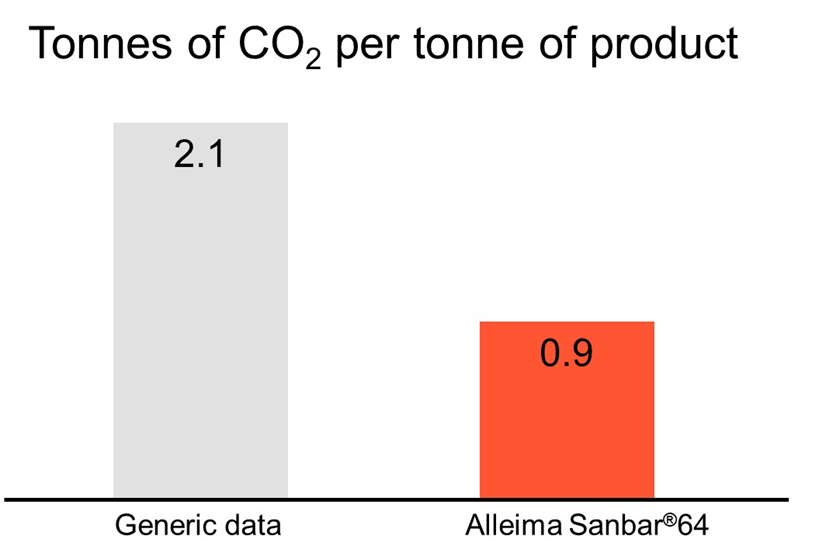

Lower emissions than generic data

RDS products of Alleima have a low carbon footprint. Alleima has reduced carbon emissions significantly through efficient processes, the use of fossil-free electricity, and dedicated investments such as conversion to fossil-free fuels for heat treatment.

In addition, by selecting suppliers with environmental awareness, and by actively choosing low-carbon alternatives, the carbon footprint of Alleima products has been significantly reduced.

A comparison was made for one of the Alleima RDS products Sanbar®64. By comparing the carbon footprint calculated with supplier specific data as well as generic database data for alloys and energy, a reduction of 57% was found.

It should be noted that the impact is expected to continue to decrease as supplier data is continuously collected and applies in the LCAs of Alleima.

Calculations tailored to the production process

The LCA calculation is tailored to the specific production process of rock drill steel at Alleima, which results in a more precise assessment of the carbon footprint and reveals significantly lower impact compared to when generic data is applied. Since the calculation of the carbon footprint includes the manufacturing processes, Alleima can provide customers with more representative impact values. Epiroc Drilling Tools, emphasize the importance of stepping away from using generic data since these impacts tend to be higher, less representative, and less reliable. By using carbon footprints from Alleima instead of generic averages in their analyses, Epiroc Drilling Tools will have more representative results.

Extracting the data

Nicole Holmgren, LCA Specialist at AlleimaA detailed model has been built to extract the data. It has been under development for some years, but it was recently decided to accelerate the LCA work by appointing a LCA specialist, Nicole Holmgren. Since then, the LCA model has been optimized and updated with production data based on the year 2022, and built on the production processes and steel recipes of Alleima, currently covering the production site in Sandviken. This enables the extraction of a product-specific cradle-to-gate carbon footprints for all Rock Drill Steel products.

Nicole Holmgren, LCA Specialist at AlleimaA detailed model has been built to extract the data. It has been under development for some years, but it was recently decided to accelerate the LCA work by appointing a LCA specialist, Nicole Holmgren. Since then, the LCA model has been optimized and updated with production data based on the year 2022, and built on the production processes and steel recipes of Alleima, currently covering the production site in Sandviken. This enables the extraction of a product-specific cradle-to-gate carbon footprints for all Rock Drill Steel products.

Providing LCA data will be a necessity to make business in the future

With LCA data on Rock Drill Steel (RDS) products, Alleima enables a green transition for the mining industry.

Epiroc Drilling Tools seek to buy steel with a minimal environmental impact as part of their commitment to sustainable practices. By incorporating third-party reviewed carbon footprint data from Alleima into their calculations they can identify areas of significant impact in their processes and make environmentally conscious choices, meeting their sustainability objectives.

In addition, communicating their own transparent and representative data on environmental impact can support differentiation in the market, providing a clear competitive advantage.

Michael Jansson believes it will be beneficial to be a step ahead in carbon footprint matters and that the LCA data from Alleima gives Epiroc Drilling Tools an advantage in the industry.

“Having a lower carbon footprint will be a competitive advantage if we can closely match prices with others and at some point, it needs to become a cost advantage to have lower emissions”, says Michael Jansson.

Michael believes that the world needs to mature a bit in this regard but maybe in the future, it will become more widespread. “For example, CBAM is now being introduced, meaning there will be a price on the carbon footprint”, he says. Michael continues his statement by emphasizing that suppliers and customers go hand in hand on this journey. "If we use greener steel, we get a greener operation at Epiroc Drilling Tools, and we can make a joint statement, contributing to a greener future together", continues Michael Jansson.

Mattias Eriksson, the Global Product Manager for Rock Drill Steel products at Alleima, also believes that the sustainability aspect of rock drill steel manufacturing will be a crucial factor in the future, hoping that it will benefit companies opting for greener steel. However, he senses that the question of climate transition hasn't resonated with all countries, emphasizing the importance of the entire rock drill steel industry recognizing the need to invest in a greener future.

The LCA data for RDS products demonstrate a positive progress in CO2 emissions and by choosing Alleima, you become a part of the sustainable transformation.

Mattias Eriksson, Global Product Manager for Rock Drill Steel products at Alleima“The LCA data for RDS products demonstrate a positive progress in CO2 emissions and by choosing Alleima, you become a part of the sustainable transformation. We always want to improve, and by doing LCA, Alleima can identify areas of high impact on its RDS products and regularly implement necessary changes”, says Mattias Eriksson.

Mattias Eriksson, Global Product Manager for Rock Drill Steel products at Alleima“The LCA data for RDS products demonstrate a positive progress in CO2 emissions and by choosing Alleima, you become a part of the sustainable transformation. We always want to improve, and by doing LCA, Alleima can identify areas of high impact on its RDS products and regularly implement necessary changes”, says Mattias Eriksson.

With its product carbon footprint data on RDS products, Alleima is an early adopter, and proud to be an industry role model, setting high standards to be followed by others.