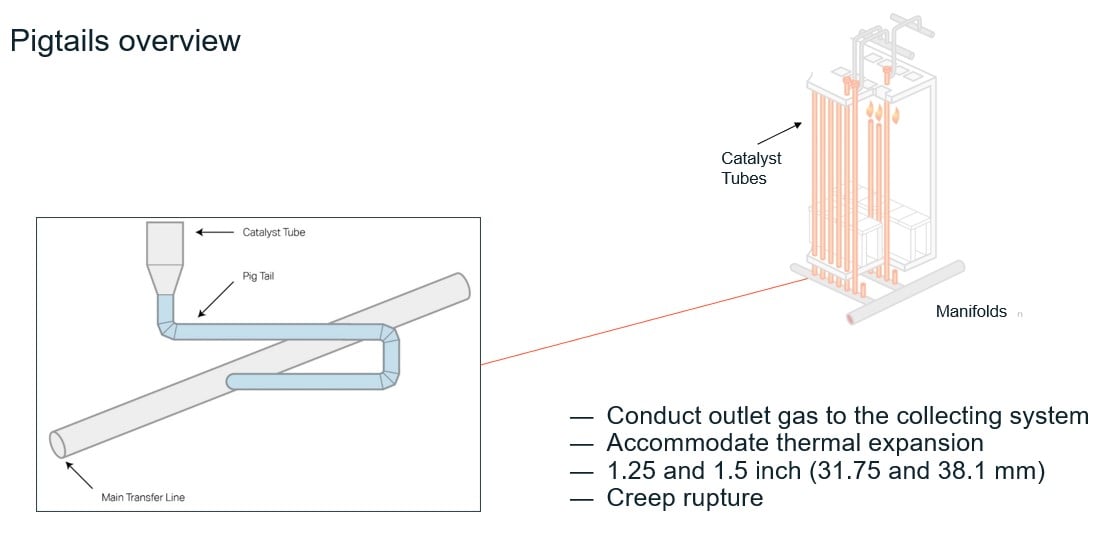

As the world combats climate change, hydrogen is rapidly becoming key to creating sustainable energy alternatives to fossil fuels. The tremendous performance of Alleima Sanicro® 31 HT in hydrogen production equipment makes it the right alloy for the right energy at the right time.

Menu

- Home

-

Products

-

Wire

- Ultra-fine medical wire

- Fine wire

- Electroplating and electropolishing of wire and parts

-

Tube, pipe, fittings and flanges

- Articles

- E-Track

- Tradeshows

- Technical services

- Approvals and standards

- Stock program

-

Tubular products

- Zirconium tubes

- Umbilical tubes

- Titanium tubes

- Thermocouple tubes

- Superheater tubes

- Subsea tubes

- Stripper tubes

- Steam generator tubes

- Scrubber tubes

- Riser tubes

- Reheater tubes

- Recuperator tubes

- Production tubing (OCTG)

- Precision tubes

- Nuclear steam generator tubing

- Nuclear fuel tubes

- Nitric acid tubes

- Muffle tubes

- Medical tubes

- Mechanical tubing

- Laying head pipe

- Lance tubes

- ISO/EN tubes

- Hydraulic and instrumentation tubing

- Hollow bar

- High-temperature tubes

- High-pressure tubes

- Heat exchanger tubes

- GDI and CNG fuel system tubes

- Furnace tubes

- Flowline piping

- Flanges

- Fittings

- Finned tubes

- Evaporator tubes

- Ethylene furnace tubes

- Downhole casing

- Control lines

- Condenser tubes

- Composite tubes

- Coiled tubing

- Chemical injection lines

- Capillary tubes

- Boiler tubes

- Bimetallic tubes

- ASME/ASTM welded pipe

- ANSI/ASME pipe

- Aerospace tubes

- High-performance materials

- List of alloys

-

Strip steel

-

Strip products

- Compressor valve steel

- Razor blade steel

- Doctor blade steel

- Precision strip steel

-

Knife steel

- Damax™ damascus steel

- Knife steel knowledge

- Size range

- Mechanical properties

- Material selection table

- Our knife steels

-

Hardening guide

- Purpose of hardening and tempering

- The hardening procedure

-

Hardening programs

- Alleima® 7C27Mo2 piece hardening

- Alleima® 7C27Mo2 batch hardening

- Alleima® 19C27 piece hardening deep freezing -70°C/95°F

- Alleima® 19C27 piece hardening

- Alleima® 19C27 batch hardening deep freezing -70°C/-95°F

- Alleima® 19C27 batch hardening

- Alleima® 14C28N piece hardening deep freezing -70°C/-95°F

- Alleima® 14C28N piece hardening deep freezing -20°C/-5°F

- Alleima® 14C28N piece hardening

- Alleima® 14C28N batch hardening deep freezing -70°C/-95°F

- Alleima® 14C28N batch hardening deep freezing -20°C/-5°F

- Alleima® 14C28N batch hardening

- Alleima® 13C26 piece hardening deep freezing -70°C/-95°F

- Alleima® 13C26 piece hardening

- Alleima® 13C26 batch hardening deep freezing -70°C/-95°F

- Alleima® 13C26 batch hardening

- Alleima® 12C27M piece hardening -20°C/-5°F

- Alleima® 12C27M piece hardening

- Alleima® 12C27M batch hardening deep freezing -20°C/-5°F

- Alleima® 12C27M batch hardening

- Alleima® 12C27 piece hardening deep freezing -70°C/-95°F

- Alleima® 12C27 piece hardening deep freezing -20°C/-5°F

- Alleima® 12C27 piece hardening

- Alleima® 12C27 batch hardening deep freezing -70°C/-95°F

- Alleima® 12C27 batch hardening deep freezing -20°C/-5°F

- Alleima® 12C27 batch hardening

- Spring steel

- Shock absorber strip steel

- Coated steel strip

- Thermocouple strip

- Resistance heating strip

- Applications

- Medical strip steel

- Size tolerances

- Shape

- Edges

- Surfaces

- List of alloys

- Alloy surcharges

-

Strip products

- Plate and sheet

- Furnace products and heating systems

- Coated Strip Steel

- Billets and blooms

- Solid bar and hollow bar

-

Wire

-

Technical center

- Corrosion tables

- Corrosion knowledge

- Safety information sheets (SIS)

- Welding guide

- Shielding the weld

- Material datasheets

- Pressure calculations

- Whitepapers

-

Webinars

- The Duplex Stainless Steel Webinar Series: Get the best of both worlds

- Carbon Capture, Utilization, and Storage: Introduction to Material Selection Webinar

- Carbon Capture, Utilization, and Storage: Introduction to Material Selection Webinar

- Captura, Utilização e Armazenamento de Carbono : Uma Introdução a Seleção de Materiais

- Fertilizer Applications: Corrosion Resistant Material Selection

- Corrosion Resistant Alloys for Heat Exchanger in the Chemical Process Industry

- Sanicro 35: Bridging the Gap Between Stainless and Nickel Alloys for Refinery Applications

- Investors

- News & media

- About us

Eduardo Perea, Senior Product Manager

Eduardo Perea, Senior Product Manager