As the world sets its sights on a more sustainable future, circularity is the word on everybody’s lips. To make the circular economy a “win-win-win” for everyone involved, Alleima is working with Danish energy solutions provider Welltec and recycling company Rimeco.

“It’s Alleima’s ambition to have > 83% production system circularity. The buy-back process we have set up with Welltec and Rimeco is just a small part of that vision,” says Brian Jørgensen, Product Area Manager, Tubular Products Nordic, and the person responsible for the Welltec account at Alleima.

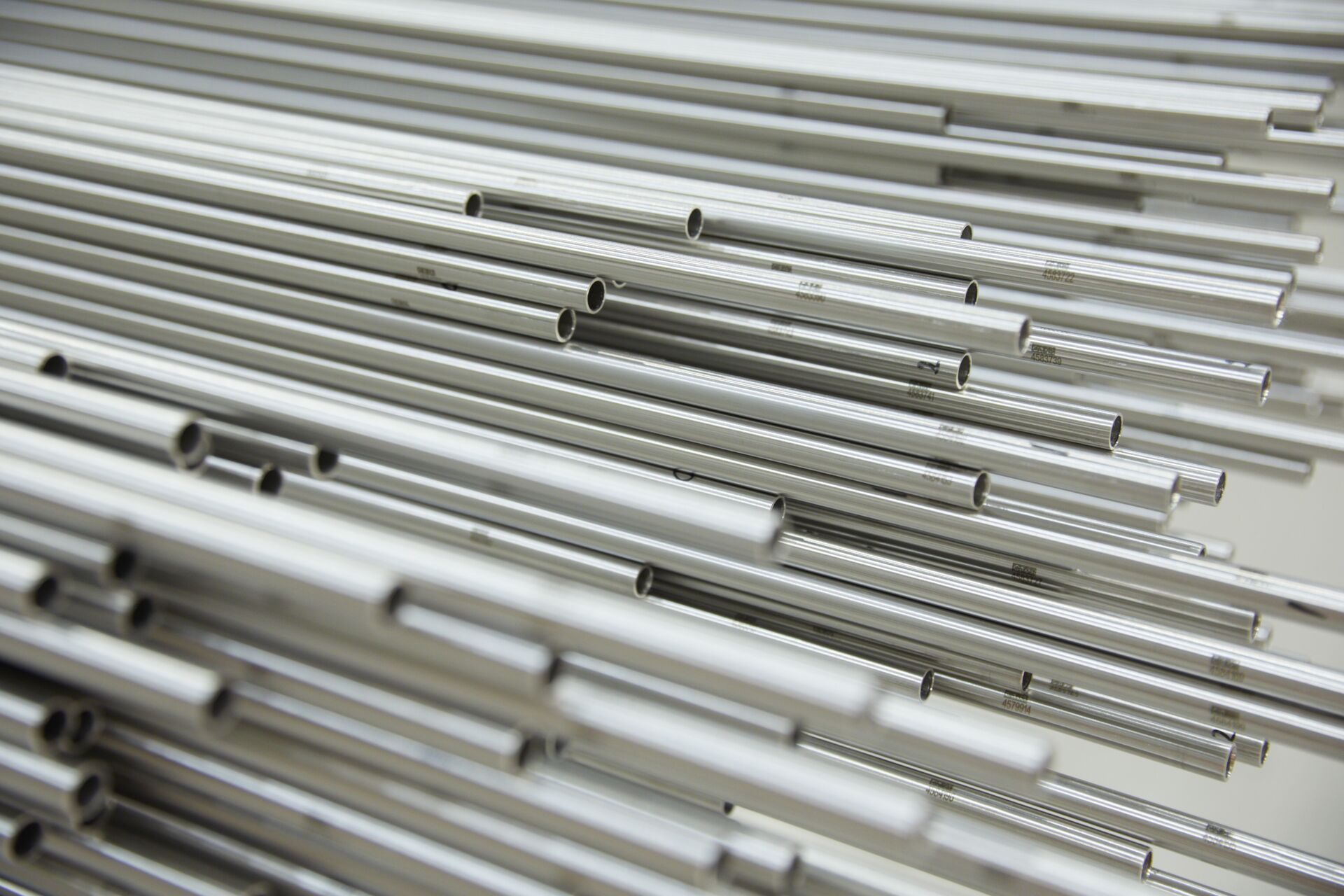

The relationship with Welltec dates back more than 35 years. The latter, a leading Danish provider of robotic well solutions for the energy industry, uses the Alleima high-alloy tubes in the production of its world-leading metal expandable packer technology.

High-alloy scrap

Welltec buys the tubes from Alleima and reworks them to fit the needs of the specific application. This typically results in some scrap being left over.

“Back in the early days of our collaboration, these valuable leftovers were sold as scrap just like any other stainless steel but now we have a better solution,” explains Brian Jørgensen.

Rimeco is a fifth-generation Danish recycling and waste management company that has been provided recycling services to Alleima since 1981. Its principal activity is the collection, recycling, and operational handling of non-ferrous and ferrous scrap and alloys in Scandinavia. As a partner to Welltec and Alleima, Rimeco has all the necessary agreements in place to allow both companies to trust it to take care of their state-of-the-art materials and proprietary designs.

Rimeco is a fifth-generation Danish recycling and waste management company that has been provided recycling services to Alleima since 1981. Its principal activity is the collection, recycling, and operational handling of non-ferrous and ferrous scrap and alloys in Scandinavia. As a partner to Welltec and Alleima, Rimeco has all the necessary agreements in place to allow both companies to trust it to take care of their state-of-the-art materials and proprietary designs.

Copyright protection during recycling

“Finding the right recycling partner is both about protecting the copyrights of our product designs and getting the right price for the scrap,” continues Hans Boldt Jensen, Head of Manufacturing, Welltec. “Rimeco delivers both, securing the value of the scrap by collecting it, sorting it into different grades, ensuring its traceability, and delivering it in such a way that it can be recycled back to its raw material form by Alleima.”

Rimeco’s Chief Executive Officer Klaus Peter Riggelsen explains that Rimeco is able to deliver the right volumes, on demand and when Alleima needs them.

“At Rimeco, our motto is ‘Reuse, Reduce, Recycle’, and we’re constantly seeking to reduce the CO2 impact across all our activities, including the collaboration with Alleima and Welltec,” he says.

When the material reaches Alleima, it will first be weighed. Next, several samples are cut from the material. They are then melted and analyzed. If the material contains welded details with different analytics, sampling becomes more complex. The results of the analysis and weight are sent back to Rimeco and, following approval, the material is stored by Alleima, ready to be loaded into a new charge that later becomes new tubes.

Klaus Peter Riggelsen says he places great value in satisfied customers and a job well done: “Rimeco operates a full chain service – where our priority is making sure our customers receive the right material on time, and every time.

Win-win-win

“You could call it a win-win-win for everyone involved,” says Brian Jørgensen. “Since the scrap that comes back to us from Welltec via Rimeco is our material, we already know its quality and, since we already have the certificates, we can reintroduce it back into our production,” he continues, adding that remelting the scrap results in minimal waste which is also better for the environment.

“What’s good for the environment is good for Welltec,” agrees Hans Boldt Jensen. “In terms of concrete wins for our company, this process enables us to secure both a higher price for our steel scrap and design protection for our products.”

![]()