Specialized ultra-fine wire forms engineered for every application

At Alleima, we recognize that every customer requires a wire solution as unique as its purpose. That is why we offer an extensive range of wire forms—each precisely engineered to meet your specific design, material, and performance requirements.

From ultra-fine single strand wire and complex multi-filar cables to cored wire for enhanced conductivity or radiopacity, and ribbon wire for space-limited designs, our solutions are tailored to your exact needs.

With access to over 200 standard alloys and a wide array of customization options, we provide one of the most comprehensive and flexible fine wire portfolios available.

From initial concept to full-scale production, we collaborate closely with your team to achieve the optimal combination of properties, dimensions, and performance. Backed by decades of materials expertise and deep industry insight, Alleima is your trusted partner in advancing next-generation medical innovations.

Ultra-fine wire options

Explore our comprehensive range of materials and wire forms to discover the ideal fit for your application.

Alleima produces fine wire in a variety of product forms, each available with a range of surface finishes to suit your needs.

Single strand

Our single strand wire delivers outstanding dimensional accuracy, surface quality, and material versatility for advanced medical, electronic, and industrial applications. Offered in a broad selection of alloys and geometries, these wires can be customized with specific coatings, finishes, and mechanical properties to match your exact requirements.

Whether used independently or within assemblies, Alleima single strand wire provides the strength, conductivity, and reliability essential for your most demanding designs

| Parameter | Specification |  |

|---|---|---|

| Diameter range | 0.010 – 1 mm (0.00039 – 0.0394 in.) | |

| Wire profiles | Round, square, rectangular | |

| Surface finishes | Gold, nickel, silver plating; oxidized | |

| Coating options | Polymer coatings available | |

| Mechanical properties | Customizable via heat and cold work |

Ribbon wire

Alleima ribbon wire delivers precise dimensional control and exceptional design flexibility for advanced medical, electronic, and industrial applications. With customizable aspect ratios and a variety of surface finishes, our ribbon wire is engineered to meet the exacting requirements of miniaturized, flexible, and space-constrained devices.

Available in a wide range of alloys and with tailored coatings or finishes, ribbon wire is ideal for applications that demand low-profile geometry, optimized winding, and enhanced flexibility.

| Parameter | Specification |  |

|---|---|---|

| Thickness range | 0.013 – 0.75 mm (0.0005 – 0.03 in.) | |

| Aspect ratio | Up to 10:1 standard; higher available upon request | |

| Wire profiles | Flat / Ribbon (rectangular cross-section) | |

| Surface finishes | Gold, nickel, silver plating; oxidized | |

| Coating options | Polymer coatings available | |

| Mechanical properties | Customizable via heat and cold work |

Multi-filar configurations

Alleima offers multi-filar configurations engineered for advanced applications requiring multichannel signal, sensing, or power delivery in compact, flexible designs. Individual single strand wires are precisely combined into multi-filar or micro-ribbon arrangements, enabling streamlined assembly, optimized space utilization, and robust mechanical performance.

Our multi-filar constructions provide extensive customization options, including the integration of dissimilar alloys, tailored coatings, and optimized bonding characteristics to meet your specific device requirements.

| Parameter | Specification |  |

|---|---|---|

| Strand count | Custom, based on application requirements | |

| Strand profiles | Round, square, rectangular | |

| Alloy combinations | Mixed alloys supported within a single cable | |

| Coating options | Polyimide, polyester-imide, polyurethane, PTFE | |

| Bond strength | Adjustable to meet assembly and handling needs | |

| Length options | Continuous or selectively bonded lengths available | |

| Color coding | Industry standard or custom color coding available |

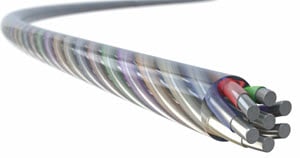

Cables

Alleima cable ables offer a highly flexible and customizable solution for advanced medical, electronic, and industrial applications. Formed by twisting or wrapping together multiple single strand or multi-filar wires, these cables deliver superior flexibility, mechanical durability, and design versatility.

Stranded cables provide a dynamic alternative to single-ended wires, allowing for deformation, independent strand movement, and incorporation of multiple alloy types within a single cable. They can be further enhanced with overall polymer or PTFE coatings to meet specific application requirements.

| Parameter | Specification |  |

|---|---|---|

| Cable diameter range | 0.018 mm – 0.25 mm (0.0007 – 0.010 in.) | |

| Cable construction | Twisted/wrapped single strand or multi-filar wires | |

| Strand coating options | Bare or individually coated strands | |

| Overall cable coating | Polymer or PTFE overcoating optional | |

| Alloy combinations | Mixed alloys supported within a single cable | |

| Cable flexibility | Highly flexible; suitable for dynamic assemblies |

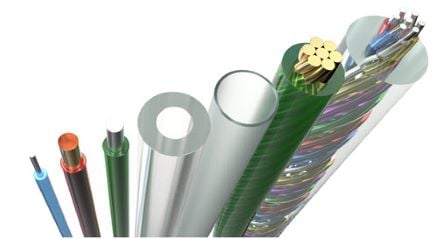

Cored wire

Alleima cored wire combines the strengths of multiple materials within a single, compact design. Featuring a shell-and-core structure, cored wire delivers enhanced electrical, mechanical, and radiographic performance—engineered specifically for advanced medical applications.

A typical configuration pairs an Alleima® F562 (MP35N) shell with a conductive or radiopaque core such as silver (Ag), platinum (Pt), gold (Au), or tantalum (Ta). This versatile structure enables optimized electrical conductivity, radiopacity, fatigue resistance, and biocompatibility—meeting the demanding requirements of next-generation medical devices.

| Parameter | Specification |  |

|---|---|---|

| Diameter range | 0.020 mm – 3 mm (0.0008 – 0.118 in.) | |

| Shell materials | Alleima® F562 (MP35N), stainless steels (12R10, 316LVM) | |

| Core materials | Silver (Ag), platinum (Pt), gold (Au), tantalum (Ta), others | |

| Standard ccore dimension | 25% by area (custom core sizes available on request) | |

| OD tolerances | Size dependent but ranging from (± 0.0025 to ± 0.025 mm) | |

| Profile | Round |

Our wire offering includes an extensive range of stainless steels, precious metals and biocompatible alloys, such as cobalt-chromium (CoCr) alloys.

| Alleima grade | UNS | ASTM |

|---|---|---|

| Alleima® 12R10 medical wire | S30200 | F899 |

| Alleima® 11R51/11R51 HV/SH medical wire | - | 302 Mod. |

| Alleima® 12R10 HV medical wire | S30400 | '304V'* |

| Alleima® 5R10/2R25 medical wire | S30400/S30403 | 304/304L |

| Alleima® 5R62/3R65 medical wire | S31600/S31603 | 316/316L |

| Alleima® 316LVM medical wire | S31673 | F138 |

| Alleima® High-N medical wire | S31675 | F1586 |

| Alleima® SAF 2205™ SH medical wire | S32205/S31803 | - |

| Alleima® SAF 2205™ medical wire | S32205/S31803 | - |

| Alleima® 4C27A medical wire | S42000 | 420F* |

| Alleima® 7C27 medical wire | S42000 | 420* |

| Alleima® 1RK91 medical wire | S46910 | - * |

* The grade meets ASTM F899.

| Alleima grade | UNS | ASTM |

|---|---|---|

| Alleima® 20AP medical wire | - | - |

| Alleima® Finemac | - | - |

| Type of alloy | UNS | ASTM |

|---|---|---|

| Platinum | P04001 | B561 |

| Platinum Iridium | P04010 | B684 |

| Platinum Tungsten | - | - |

| Platinum Clad Tantalum | - | - |

| Pure Gold | P00001 | F72 |

| Gold-plated Copper | - | B488 |

| Silver | P07001 | B413 |

| Alleima grade | UNS | ASTM |

|---|---|---|

| Alleima® F562 medical wire | R30035 | F562 |

| Alleima® F562 LTi medical wire* | R30035 | F562 |

* Low titanium version of Sandvik F562

| Constantan |

| Copper |

Kanthal Resistance Alloys

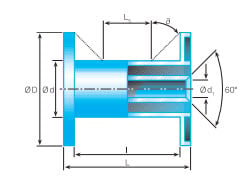

Alleima offers a variety of spool types. Contact your sales representatives for more information if some particular spool type is required.

American standard |

|

| Spool type | D in. | d in. | d1 in. | L in. | I in. | Wire type |

|---|---|---|---|---|---|---|

| 2.125" Flange | 2.125 | 1.375 | 5/8 | 1.375 | 1 | 0.0005 - 0.002 |

| 2.5" Flange | 2.5 | 1.76 | 5/8 | 3,376 | 3 | 0.007 - 0.0031 |

| 3.15" Flange | 3.15 | 1.97 | 5/8 | 3.15 | 2.52 | 0.002 - 0.0063 |

| 3.5" Flange | 3.5 | 2.125 | 2.125 | 2.438 | 2.125 | |

| 5" Flange | 5 | 3 | 5/8 | 4.11 | 3.5 | 0.0035 - 0.113 |

| 6" Flange | 6 | 3.5 | 5/8 | 4.11 | 3.5 | 0.005 - 0.0253 |

| PT 4 Tapered | 5.5 & 4.875 | 4.375 & 3.875 | 1 | 7.875 | 6.688 | 0.003 - 0.008 |

| PT 10 Tapered | 7.087 x 6.300 | 4.331 x 3.780 | 1 | 9 | 7.875 | 0.004 - 0.010 |

| 12" Reel | 11.75 | 8 | 2 | 3.938 | 3.62 | |

| Anodized Band Spool | 2.24 | 1.98 | 1.93 | 1.1 | 1 | Bonding wire |

Metric

| Spool type | D mm | d mm | d1 mm | L mm | I mm | Wire size mm Ø | Normal net weight, kg |

|---|---|---|---|---|---|---|---|

| C 1/4 | 64 | 44 | 16 | 61 | 51 | <0.030 | 0.05 - 0.25 |

| C 1/2 | 64 | 44 | 16 | 86 | 76 | 0.030 - 0.099 | 0.5 |

| B 1 | 75 | 40 | 16 | 120 | 100 | 0.1 - 0.199 | 1.0 |

| B 2 | 90 | 40 | 16 | 120 | 100 | 0.20 - 0.25 | 2.0 |

| B 4 | 120 | 50 | 16 | 120 | 100 | 0.26 - 0.50 | 4.0 |

Standard DIN spools

| Spool type | D mm | d mm | d1 mm | L mm | I mm | Wire size mm Ø | Normal net weight, kg |

|---|---|---|---|---|---|---|---|

| DIN 50 | 50 | 32 | 11 | 50 | 38 | 0.015 - 0.04 | 0.10 |

| DIN 63 | 63 | 40 | 11 | 63 | 49 | 0.015 - 0.04 | 0.20 |

| DIN 80 | 80 | 50 | 16 | 80 | 64 | 0.05 - 0.099 | 0.75 |

| DIN 100 | 100 | 63 | 16 | 100 | 80 | 0.10 - 0.50 | 1.5 |

| DIN 125 | 125 | 80 | 16 | 125 | 100 | 0.15 - 0.80 | 3.0 |

| DIN 160 | 160 | 100 | 22 | 160 | 128 | 0.25 - 0.71 | 5.0 |

| DIN 200 | 200 | 125 | 36 | 200 | 160 | 0.4 - 0.81 | 10.0 |

| DIN 250 | 250 | 160 | 36 | 200 | 160 | 0.4 - 1.5 | 20 |

| DIN 355 | 355 | 225 | 36 | 200 | 162 | 1.0 - 3.0 | 40 |

| SK 460 | 460 | 318 | 305 | 105 | 91 | 0.25 - 1.8 | 45 |

Steeger bobbins

| Sizes D / d x I |

|---|

| 40 / 30 x 26 mm |

| 40 / 16 x 26 mm |

| 40 / 25 x 26 mm |

Wire also in larger dimensions

Fine wire plays a critical role in high-precision applications where properties like conductivity, resistance, mechanical strength, or sensitivity to temperature and pressure are essential. Alleima offers a broad selection of stainless steel and nickel-based alloys in fine wire sizes, engineered for performance in heating, sensing, and other demanding environments.

Alleima also offers larger-diameter wire commonly used in industrial applications. Click here to learn more.