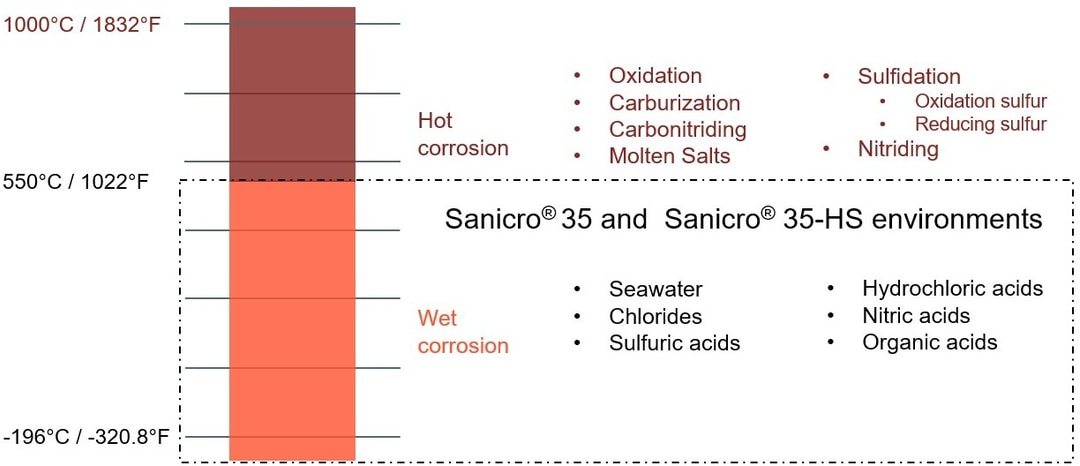

Corrosive environments

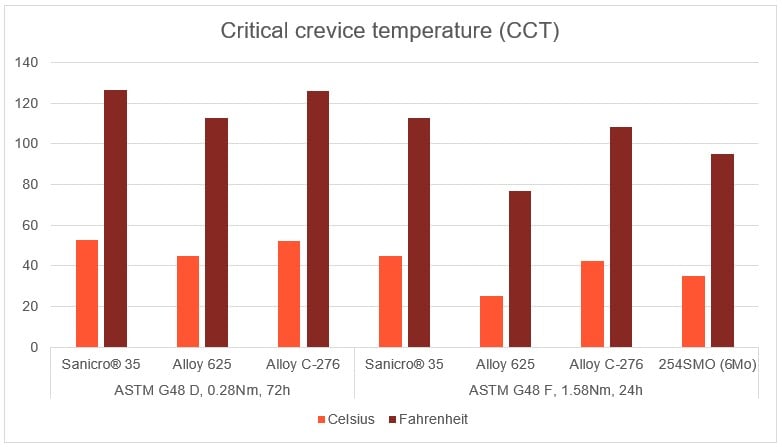

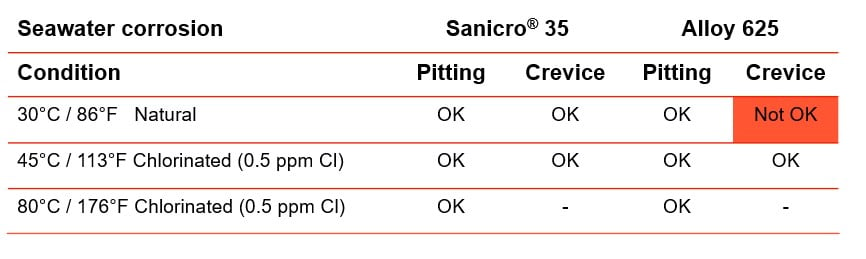

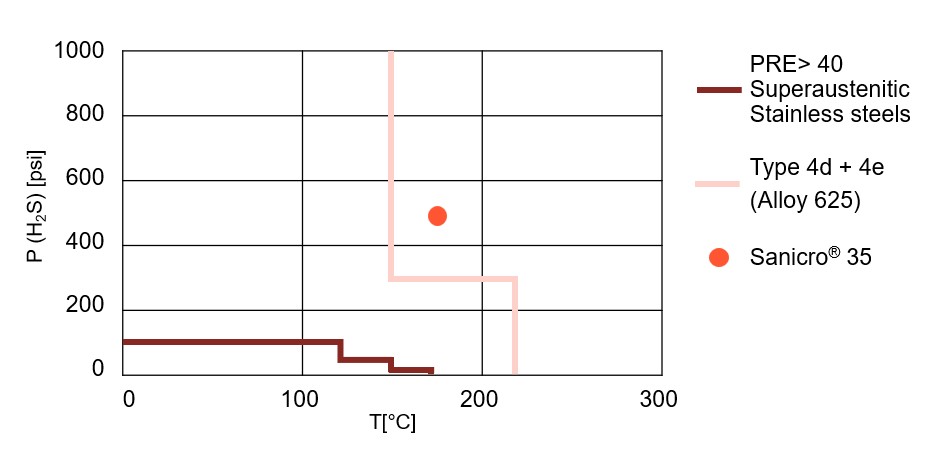

Sanicro® 35 is most suitable in wet corrosion environments. The advanced alloy composition not only enhances resistance to a wide range of corrosive agents - including chlorides, sulfuric, hydrochloric, and nitric acids - but also ensures stability in challenging applications exposed to wet environments.