Sanicro® 35 is a next‑generation alloy, developed and patented by Alleima, engineered to set a new benchmark in highly corrosive environments.

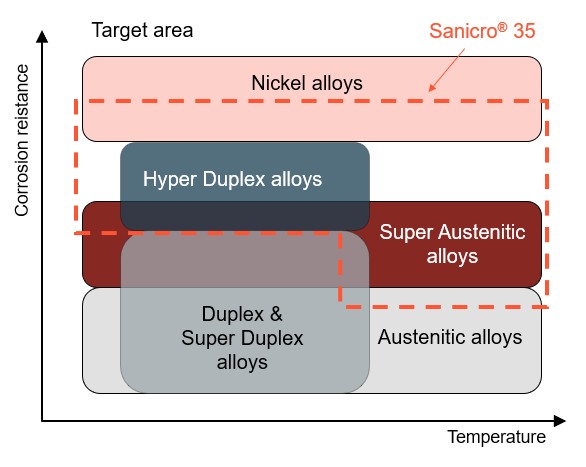

The development of Sanicro® 35 began with a clear industry challenge. Conventional duplex and austenitic stainless steels could not deliver the required performance, while nickel‑based alloys are often too costly. Alleima set out to close this critical materials gap with a solution that combines high performance with cost efficiency.

Target Area

Features

- Combines the best features of a super

austenitic stainless steel and a nickel alloy - Performance that can match

several nickel-based materials

Possibilities

- Cost effective solution to nickel alloys

- Upgrade possibilities vs. current super austenitic and duplex stainless steels

A Metallurgical Breakthrough

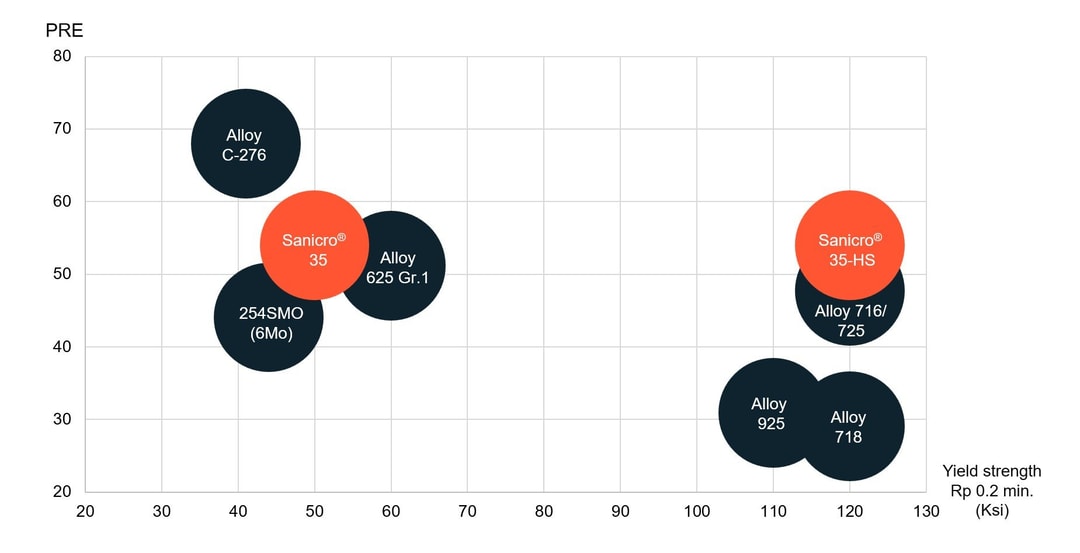

To achieve this performance the Alleima R&D team optimized the chemical composition, resulting in a PRE value of 52. This engineered chemistry delivers reliability in demanding applications where material failure is not an option.

The Result

Sanicro® 35 stands as a unique alloy that bridges the gap between stainless steels and nickel‑based alloys - offering the strength, corrosion resistance, and stability of premium materials at a competitive total cost of ownership.