Sanicro® 23 is a super austenitic stainless steel with excellent corrosion resistance, for service in sea-water applications and in highly corrosive environments.

The grade is characterized by:

- Excellent resistance to pitting and crevice corrosion

- Excellent resistance to stress corrosion cracking (SCC)

- High resistance to general corrosion in acid environments

- High resistance to general corrosion in caustic environments

- High resistance to erosion corrosion

- Very high mechanical strength

- Good weldability using nickel alloy consumables

Standards

- UNS: S31266

- EN Number: 1.4659

- EN Name: X1 CrNiMoCuNW 24-22-6

Product standards

- Seamless tube and pipe: ASTM A213, A312

- Forgings and fittings: ASTM A182, A403

- Plate, sheet and strip: ASTM A240, A480

Approvals

Approved by the American Society of Mechanical Engineers (ASME) for use in accordance with ASME Boiler and Pressure Vessel Code, section VIII, division I and II.

Approved by NACE MR0175/ISO 15156 (Petroleum and natural gas industries - Materials for use in H2S-containing Environments in oil and gas production - Part 3: Cracking-resistant CRAs (corrosion resistant alloys and other alloys) (Published:2015), in solution-annealed condition.

Chemical composition (nominal) %

| C | Si | Mn | P | S | Cr | Ni | Mo | W | Cu | N |

|---|---|---|---|---|---|---|---|---|---|---|

| ≤0.020 | ≤0.5 | 3.0 | ≤0.030 | ≤0.010 | 24 | 23 | 5.5 | 2 | 1.5 | 0.45 |

Applications

Due to its extremely good pitting and crevice corrosion properties, Sanicro® 23 is particularly suitable for heat exchangers where seawater is used for cooling or heating. The grade also has high resistance to general corrosion in acid and caustic environments.

Corrosion resistance

General corrosion

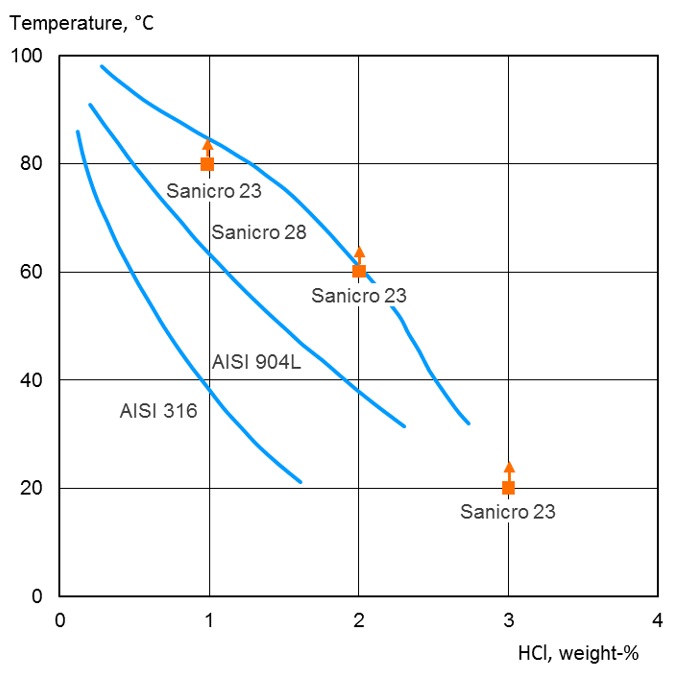

Sanicro® 23 has a good resistance to hydrochloric acid compared to stainless steels with a lower chromium and molybdenum content and can, therefore, be useful in environments containing small amounts of hydrochloric acid, see Figure 1.

Figure 1. Isocorrosion in hydrochloric acid. The curves represent a corrosion rate of 0.1 mm/year. Sanicro® 23 shows a corrosion rate far less than 0.1 mm/year at the points that are indicated.

Figure 1. Isocorrosion in hydrochloric acid. The curves represent a corrosion rate of 0.1 mm/year. Sanicro® 23 shows a corrosion rate far less than 0.1 mm/year at the points that are indicated.

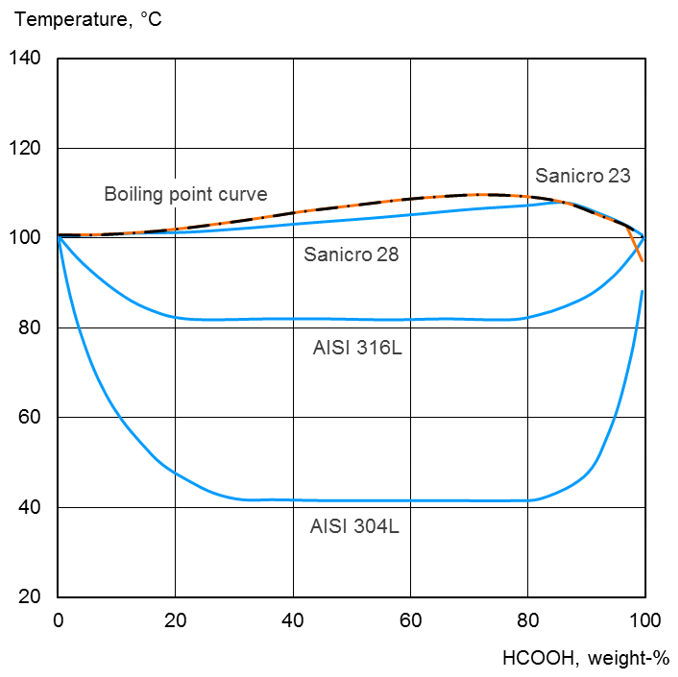

Sanicro® 23 has high resistance to formic acid and can resist boiling solutions in the concentration interval 0-90%. Isocorrosion diagram for formic acid can be seen in Figure 2.

Figure 2. Isocorrosion in formic acid. The curves represent a corrosion rate of 0.1 mm/year.

Figure 2. Isocorrosion in formic acid. The curves represent a corrosion rate of 0.1 mm/year.

Sanicro® 23 also performs well in mixtures of formic acid and acetic acid, see Table 1.

Table 1. Corrosion rate of Sanicro 23 in mixtures of acetic acid (CH3COOH) and formic acid (HCOOH) at boiling conditions.

| Concentration CH3COOH, % | 50 | 50 | 50 | 50 |

| Concentration HCOOH, % | 10 | 15 | 20 | 25 |

| Corrosion rate, mm/year | 0 | 0 | 0.06 | 0.06 |

Sanicro® 23 has high general corrosion resistance in acidic environments and shows high general corrosion resistance in caustic environments, see Table 2.

Table 2. Corrosion rate of Sanicro® 23 in sodium hydroxide.

| Concentration NaOH, % | 40 | 50 | 60 | 70 |

| Temperature, °C | 120 | 120 | 120 | 120 |

| Corrosion rate, mm/year | 0.01 | 0.07 | 0.08 | 0.08 |

Pitting corrosion

One of the main advantages with Sanicro® 23 is that it has excellent resistance to pitting corrosion. The excellent pitting resistance comes from the high contents of chromium, molybdenum, tungsten, and nitrogen. The PRENW-number can be used to compare and rank alloys with respect to the chemical composition and possibility to resist pitting. The PRENW is defined as, in weight-%;

PRENW = %Cr + 3.3 (%Mo + 0.5 x %W) +16 x %N

The nominal PRENW value for Sanicro® 23 is ~52, comparable to nickel alloy Sanicro® 60 (Alloy 625). This is significantly higher than e.g. the PRENW values for super duplex and 6 Mo austenitic grades which are commonly used in seawater applications. As an example, Sandvik SAF 2507® and Sandvik 254 SMO have a minimum PRENW -value of 42.5.

The critical pitting temperature (CPT) has been determined in 6% FeCl3 according to ASTM practice E. The CPT has also been determined in a potentiostatic test in a 3M MgCl2 solution. The test was performed in a modified ASTM G150 test where the solution was changed from 1M NaCl to allow the measurement of high CPT-values. The measured CPT-values can be seen in Table 3.

Table 3. CPT-values for Sanicro® 23. The CPT was measured on Sanicro® 23 heat exchanger tubes.

| Alloy | CPT per ASTM G48 E | CPT per mod. G150 in 3M MgCl2 |

| Sanicro® 23 | >85°C (95°C*) | 95°C |

*According to the standard ASTM G48, the method was developed to be used up to 85°C.

Crevice corrosion

High crevice corrosion resistance is just as important as good pitting resistance since crevices can rarely be totally avoided. Sanicro® 23 has high crevice corrosion resistance in chloride environments. The critical crevice temperature (CCT) has been determined by potentiostatic tests in 1M NaCl and 3M MgCl2 solution, see Table 4.

Table 4. CCT-values for Sanicro® 23. The CCT was measured on Sanicro® 23 heat exchanger tubes. The crevice formers used were in accordance with ISO 18070 and the applied momentum was 1.58 Nm. The applied potential was 700 mV vs. SCE as per ASTM G150.

| Method | CCT |

| ASTM G150 | 85°C* |

| Mod. G150, 3M MgCl2 | 75°C |

*The same CCT was measured in neutral solution and in acidified solution at pH 3.

The crevice corrosion resistance is a property where Sanicro® 23 has an advantage compared to many nickel alloys. In Table 5 the CCT per ASTM G48 D is compared for Sanicro® 23 and Sanicro® 60.

Table 5. CCT in acidified ferric chloride per ASTM G48 D. The CCT was measured on heat exchanger tubes. The crevice formers used were in accordance with ISO 18070.

| Alloy | ASTM G48 D, at 0.28 Nm | ASTM G48 D, at 1.58 Nm |

| Sanicro® 23 | 45°C | 45°C |

| Sanicro® 60 (UNS N06625) | 30°C | 20°C |

Fabrication

Bending

The force needed for bending Sanicro® 23 is higher than that for standard austenitic stainless steels which is a natural consequence of the higher yield strength. The excellent formability of Sanicro® 23 permits cold bending to tight bending radii.

Expanding

Sanicro® 23 is expanded into tube sheets in the same way as standard austenitic stainless steels. Higher forces may be required since Sanicro® 23 has a high yield and tensile strength.

Forms of supply

Sanicro® 23 can be supplied as seamless tube and pipe.

Heat treatment

Tubes are delivered in the annealed condition. If additional heat treatment is needed after further processing, the following is recommended.

Solution annealing

1150-1200°C (2100-2190°F), rapid cooling preferably in water.

Mechanical properties

At 20oC, metric units

| Proof strength | Tensile strength | Elongation | Hardness | |

|---|---|---|---|---|

| Rp0.2a | Rp1.0a | Rm | A2" | HRB |

| MPa | MPa | MPa | % | |

| ≥420 | ≥440 | ≥750 | ≥35 | ≤100 |

At 68oF, imperial units

| Proof strength | Tensile strength | Elongation | Hardness | |

|---|---|---|---|---|

| Rp0.2a | Rp1.0a | Rm | A2" | HRB |

| ksi | ksi | ksi | % | |

| ≥61 | ≥64 | ≥109 | ≥35 | ≤100 |

1 MPa = 1 N/mm2

a) Rp0.2 and Rp1.0 corresponds to 0.2% and 1.0% offset yield strength.

At high temperatures

Intermetallic phases are precipitated within the temperature range of 600–1100°C (1110–2010°F). Therefore, the steel should not be exposed to these temperatures for prolonged periods.

Metric units

| Temperature | Proof strength | Tensile strength | Elong. |

| Rp0.2 | Rm | A | |

| °C | MPa | MPa | % |

| min. | min. | min. | |

| 100 | 350 | 730 | 35 |

| 200 | 300 | 660 | 35 |

| 300 | 280 | 630 | 35 |

| 400 | 270 | 610 | 35 |

Imperial units

| Temperature | Proof strength | Tensile strength | Elong. |

| Rp0.2 | Rm | A | |

| °F | ksi | ksi | % |

| min. | min. | min. | |

| 200 | 51 | 107 | 35 |

| 400 | 43 | 95 | 35 |

| 600 | 40 | 91 | 35 |

| 800 | 39 | 88 | 35 |

Physical properties

Density: 8.2 g/cm3, 0.29 lb/in3

Thermal conductivity

| Temperature, °C | W/m °C | Temperature, °F | Btu/ft h°F |

| 20 | 11 | 68 | 6.5 |

| 100 | 12.5 | 200 | 7.0 |

| 200 | 14 | 400 | 8.0 |

| 300 | 16 | 600 | 9.5 |

| 400 | 17.5 | 800 | 10.5 |

Specific heat capacity

| Temperature, °C | J/kg °C | Temperature, °F | Btu/ft h°F |

| 20 | 460 | 68 | 0.19 |

| 100 | 490 | 200 | 0.20 |

| 200 | 510 | 400 | 0.21 |

| 300 | 530 | 600 | 0.22 |

| 400 | 540 | 800 | 0.23 |

Thermal expansion

Metric units, x10-6/°C

| Temperature, °C | 30-100 | 30-200 | 30-300 | 30-400 |

| Sanicro® 23 | 15.5 | 16.0 | 16.5 | 17.0 |

| Carbon steel | 12.5 | 13.0 | 13.5 | 14.0 |

| ASTM 316L | 16.5 | 17.0 | 17.5 | 18.0 |

Imperial units, x10-6/°F

| Temperature, °F | 86-200 | 86-400 | 86-600 | 86-800 |

| Sanicro® 23 | 8.5 | 9.0 | 9.0 | 9.5 |

| Carbon steel | 7.0 | 7.0 | 7.5 | 8.0 |

| ASTM 316L | 9.5 | 9.5 | 10.0 | 10.0 |

Resistivity

| Temperature, °C | μΩm | Temperature, °F | μΩinch |

| 20 | 1.0 | 68 | 39 |

Modulus of elasticity, x103

| Temperature, °C | MPa | Temperature, °F | ksi |

| 20 | 195 | 68 | 29.5 |

| 100 | 190 | 200 | 28.0 |

| 200 | 185 | 400 | 26.5 |

| 300 | 175 | 600 | 25.5 |

| 400 | 170 | 800 | 24.0 |

Welding

The weldability of Sanicro® 23 is good. Suitable methods of fusion welding are manual metal-arc welding (MMA/SMAW) and gas-shielded arc welding, with the TIG/GTAW method as first choice. For TIG/GTAW welding, it is recommended to use Ar+2%N2 as shielding and backing gas.

In common with all fully austenitic stainless steels, Sanicro® 23 has low thermal conductivity and high thermal expansion. Welding plans should therefore be carefully selected in advance, so that distortions of the welded joint are minimized. If residual stresses are a concern, solution annealing can be performed after welding.

For Sanicro® 23, heat-input of <1.2 kJ/mm and interpass temperature of <100°C (210°F) are recommended. A string bead welding technique should be used.

Nickel alloys with high molybdenum and chromium must be used as filler metals to have good corrosion resistance in as welded condition.

Recommended filler metals

TIG/GTAW or MIG/GMAW welding

ISO 18274 S Ni 6059/AWS A5.14 ERNiCrMo-13 (e.g. Exaton Ni59)

MMA/SMAW welding

ISO 14172 E Ni 6059/AWS A5.11 ENiCrMo-13 (e.g. Exaton Ni59)

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.