SAF™ 3007 is a super-duplex (austenitic-ferritic) stainless steel optimized for service in highly corrosive chloride environments where a high strength material is required.

The grade is characterized by:

- Excellent resistance to stress corrosion cracking (SCC) in chloride-bearing environments

- Excellent resistance to pitting and crevice corrosion

- Excellent mechanical strength

- Physical properties that offer design advantages

- Good weldability

Standards

- ASTM: A789, A790

- UNS: S83072

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | W | Mo | Cu | N |

|---|---|---|---|---|---|---|---|---|---|---|

| ≤0.030 | 0.2 | 1.0 | ≤0.030 | ≤0.030 | 30 | 7 | 3.4 | 1.0 | ≤0.30 | 0.40 |

Applications

SAF™ 3007, with its excellent strength, pitting and crevice corrosion resistance, and good weldability, is an optimal choice for umbilical tubing in subsea applications. Its unique properties make it highly effective in handling seawater and operating in high-pressure environments.

Corrosion resistance

Pitting and crevice corrosion

SAF™ 3007 is designed for demanding environments where a high mechanical strength in combination with high corrosion resistance is desired and where, additionally, welding is not tolerable to impair the well-adjusted properties.

A parameter for comparing the resistance to pitting in chloride environments is the PRE number (Pitting Resistance Equivalent).

A modified PRE formula for stainless steel containing tungsten is defined as (in weight %):

PRE = %Cr + 3.3 x (%Mo + ½ x %W) + 16 x %N

The minimum PRE value for SAF™ 3007 is 43.

SAF™ 3007 has excellent resistance to both pitting and crevice corrosion. The tables below specify the resistance to localized corrosion induced by chlorides by the critical pitting temperature (CPT) and the critical crevice temperature (CCT).

The CPT and CCT have been determined according to ASTM G48 method E and method F respectively, in acidified 6 % ferric solution (FeCl3) and according to ASTM G150 in 1 M sodium chloride (NaCl).

In the measurements of CPT, test coupons with surface wet ground with P120 grit paper were tested by the ASTM G48 method E. For ASTM G150, test coupons with surface wet ground with P600 were tested, applied potential was 700 mV vs. SCE.

| Alloy | CPT | CPT | |

| °C | °C | ||

| PRE | ASTM G48 E | ASTM G150 | |

| SAF™ 3007 | ≥ 43.0 | 70 | 81 |

In the measurements of CCT, test coupons wet ground with P120 were tested in ASTM G48 method F. For ASTM G150, test coupons wet ground with P600 were tested, applied potential was 700 mV vs. SCE.

| Alloy | CCT | CCT | |

| °C | °C | ||

| PRE | ASTM G48 F a) | ASTM G150 b) | |

| SAF™ 3007 | ≥ 43.0 | 30 | 79 |

| a) Applied momentum of 1.58 Nm b) Crevice formers according to ISO 18070 with applied momentum of 3 Nm |

|||

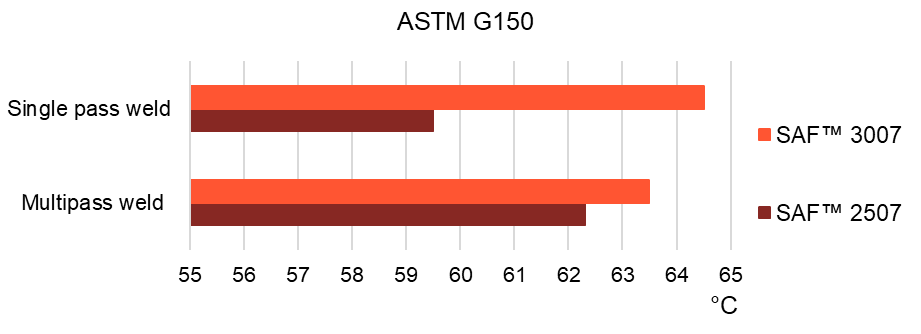

Orbitally welded tubes of SAF™ 3007 pass the ASTM G48 method A requirements with a CPT greater than 40 °C. SAF™ 3007, part of Alleima's duplex stainless steel family, is alloyed with tungsten (W) instead of molybdenum (Mo) to maintain corrosion resistance after welding, crucial for the umbilical application. The CPT of SAF™ 3007 orbitally welded tubes is compared to SAF™ 2507 in a sodium chloride (NaCl) environment.

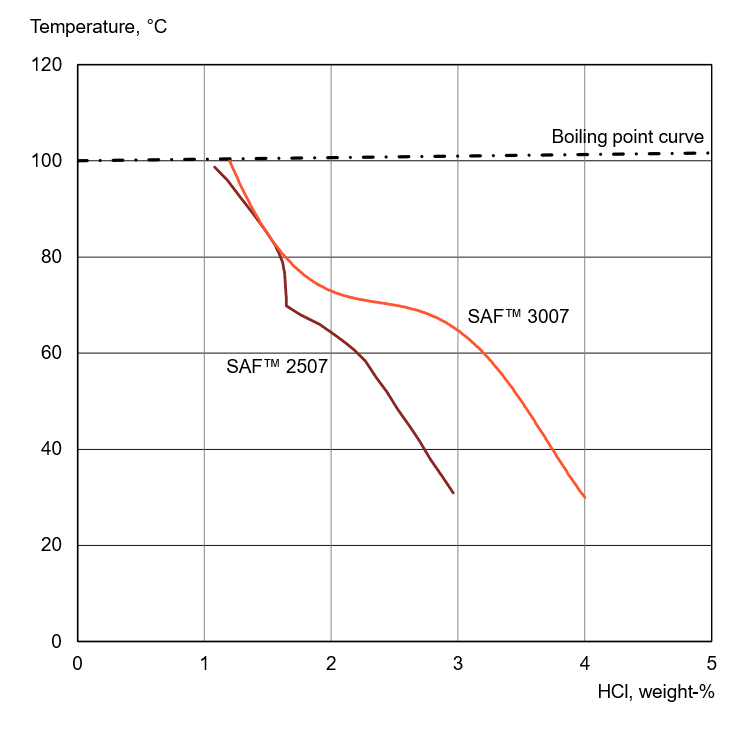

General corrosion

SAF™ 3007 has high resistance to hydrochloric acid (HCl), exceeding the resistance of SAF™ 2507. The graph below shows the iso-corrosion rate in hydrochloric acid, the curves represent a corrosion rate of 0.1 mm/year (4 mpy) in stagnant test solution.

Forms of supply

SAF™ 3007 can be supplied as seamless straight tubes or tubes coiled on reels, in bright annealed condition. SAF™ 3007 is supplied in dimensions from inner diameter 9.53 mm (⅜ ”) up to 63.5 mm (2½ “), outer diameter 13 mm (½ ”) to 73 mm (2 ⅞ ”) . Please contact Alleima for more information regarding other product forms.

Heat treatment

Tubes are delivered in solution annealed condition. If additional heat treatment is needed after further processing, please contact Alleima.

Mechanical properties

The following tables apply to material in cold pilgered and solution annealed condition. The listed values are guaranteed for tubes.

At 20 °C (68 °F)

Metric units

| Inner diameter | Wall thickness | Proof strength | |

| from | to | Rp0.2 a) | |

| mm | mm | mm | MPa |

| min. | |||

| ≥ 9.53 | ≤ 15.88 | ≤ 3 | 800 |

| > 3 | 780 | ||

| > 15.88 | ≤ 25.40 | ≤ 5 | 780 |

| > 5 | 760 | ||

| > 25.40 | ≤ 63.50 | ≤ 5 | 760 |

| > 5 | 740 | ||

| 1 MPa = 1 N/mm2 a) Rp0.2 corresponds to 0.2% offset yield strength |

|||

| Tensile strength | Yield / Tensile strength ration |

Elong. | Hardness |

| Rm | Rp0.2 a) / Rm | A2” | HRC |

| MPa | % | ||

| min. | max. | min. | max. |

| 950 | 0.9 | 25 | 35 |

| 1 MPa = 1 N/mm2 a) Rp0.2 corresponds to 0.2% offset yield strength |

|||

Imperial units

| Inner diameter | Wall thickness | Proof strength | |

| from | to | Rp0.2 a) | |

| inch | inch | inch | ksi |

| min. | |||

| ≥ 3/8 | ≤ 5/8 | ≤ 0.12 | 116 |

| > 0.12 | 113 | ||

| > 5/8 | ≤ 1 | ≤ 0.20 | 113 |

| > 0.20 | 110 | ||

| > 1 | ≤ 2½ | ≤ 0.20 | 110 |

| > 0.20 | 107 | ||

| a) Rp0.2 corresponds to 0.2% offset yield strength | |||

| Tensile strength | Yield / Tensile strength ratio, max |

Elong. | Hardness |

| Rm | Rp0.2 a) / Rm | A2” | HRC |

| ksi | % | ||

| min. | min. | min. | max. |

| 138 | 0.9 | 25 | 35 |

| a) Rp0.2 corresponds to 0.2% offset yield strength | |||

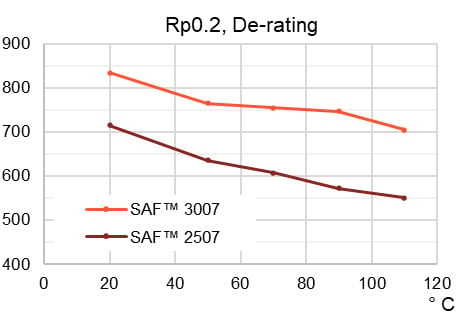

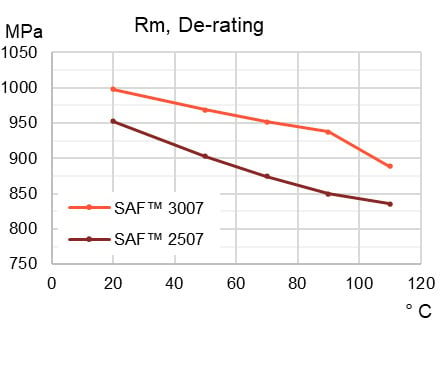

At high temperatures

De-rating curves comparing SAF™ 3007 with SAF™ 2507. The curves are based on measured values, not representing guaranteed minimum values, on seamless tubes in final condition.

Physical properties

Density

7.9 g/cm3, 0.28 lb/in3

Permeability

| µr (max) | Hc | Br | |

| A/m | T | ||

| SAF™ 3007 | 35 | 700 | 0.04 |

Thermal conductivity

Metric units

| Temperature,°C | 20 | 100 | 200 | 300 | 400 |

| W/(m °C) | |||||

| SAF™ 3007 | 12 | 13 | 15 | 16 | 18 |

Imperial units

| Temperature,°F | 68 | 200 | 400 | 600 | 700 |

| Btu/(ft h °F) | |||||

| SAF™ 3007 | 7 | 7 | 8 | 10 | 10 |

Specific heat capacity

Metric units

| Temperature, °C | 20 | 100 | 200 | 300 | 400 |

| J/(kg °C) | |||||

| SAF™ 3007 | 460 | 490 | 520 | 560 | 600 |

Imperial units

| Temperature, °F | 68 | 200 | 400 | 600 | 700 |

| Btu/(lb °F) | |||||

| SAF™ 3007 | 0.11 | 0.12 | 0.13 | 0.13 | 0.14 |

Thermal expansion

Metric units, x10-6/°C

| Temperature, °C | 30-100 | 30-200 | 30-300 | 30-400 |

| SAF™ 3007 | 12.5 | 13.0 | 13.0 | 13.5 |

Imperial units, x10-6/°F

| Temperature, °F | 86-200 | 86-400 | 86-600 | 86-700 |

| SAF™ 3007 | 7.0 | 7.0 | 7.5 | 7.5 |

Resistivity

Metric units

| Temperature, °C | 0 | 20 | 100 | 200 | 300 |

| µΩm | |||||

| SAF™ 3007 | 0.85 | 0.86 | 0.89 | 0.89 | 0.92 |

Imperial units

| Temperature, °F | 32 | 68 | 200 | 400 | 600 |

| µΩin | |||||

| SAF™ 3007 | 33.3 | 33.8 | 34.8 | 35.2 | 36.4 |

Modulus of elasticity

Metric units x103

| Temperature, °C | 20 | 100 | 200 | 300 |

| MPa | ||||

| SAF™ 3007 | 195 | 190 | 182 | 173 |

Imperial units, x103

| Temperature, °F | 68 | 200 | 400 | 500 |

| ksi | ||||

| SAF™ 3007 | 28 | 28 | 26 | 26 |

Poisson Ratio

0.35-0.37

Welding

The weldability of SAF™ 3007 is good. Welding is preferably performed with the TIG/GTAW method and a shielding gas mixture of argon with 2% nitrogen. Preheating and subsequent heat treatment is normally not necessary.

For SAF™ 3007 heat input of 0.2-1.5 kJ/mm and inter-pass temperature of <150 °C (300 °F) are recommended.

Matching filler metals are recommended to obtain a weld metal with optimum corrosion resistance and mechanical properties. For TIG/GTAW welding the use of Alleima 30.8.1.LW (UNS S83072) is recommended.

All-weld metal of Alleima 30.8.1.LW give tensile properties of Rp0.2 >800 MPa, Rm > 950 MPa and A 20% Impact toughness at -46 °C (-51 °F) > 55 J.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.