Alleima® 3R64 is an austenitic stainless steel with a high molybdenum content. The grade is characterized by improved resistance to general and pitting corrosion in comparison with ASTM 316L.

Standards

- ASTM: TP317L

- UNS: S31703

- SS: 2367

Product standards

Seamless tube and pipe

ASTM A213, A312

SS 142367

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|

| ≤0.030 | 0.4 | 1.7 | ≤0.030 | ≤0.015 | 18.5 | 14.5 | 3.1 |

Applications

Alleima® 3R64 can be used for a wide range of industrial applications where steels of type ASTM 304 and 304L or even ASTM 316L have insufficient corrosion resistance. Typical examples are heat exchangers, condensers, pipelines, cooling and heating coils in the chemical, petrochemical, pulp and paper and food industries.

Corrosion resistance

Owing to its high molybdenum content Alleima® 3R64 possesses improved resistance compared to ASTM 316/316L in a majority of chloride and acidic environments.

General corrosion

Alleima® 3R64 has good resistance in:

- Organic acids at high concentrations and moderate temperatures

- Inorganic acids, e.g. phosphoric and sulphuric acids at moderate concentrations and temperatures. The steel can also be used in sulphuric acid of concentrations above 90% at low temperature

- Salt solutions, e.g. sulphates, sulphides and sulphites caustic environments

The following data illustrate the improved resistance of Alleima® 3R64 vs ASTM 316, although the corrosion rates at the majority of temperatures are unacceptably high for both grades.

Table 1. General corrosion resistance of Alleima® 3R64 and ASTM 316 in boiling formic acid.

|

Formic acid, wt-%

|

Corrosion rate, mm/year

|

|

|---|---|---|

| Alleima 3R64 | ASTM 316 | |

| 5 | 0.12 | 0.18 |

| 10 | 0.20 | 0.3 |

| 25 | 0.35 | 0.6 |

| 50 | 0.45 | 0.6 |

| 80 | 1.0 | 1.5 |

| 90 | 0.8 | 1.8 |

| 100 | 0.4 | 0.6 |

Intergranular corrosion

Owing to its low carbon content Alleima® 3R64 possesses a low risk for intergranular corrosion after e.g. welding operations.

Pitting and crevice corrosion

The pitting corrosion resistance of stainless steels is primarily determined by the contents chromium, molybdenum and nitrogen. The Pitting Resistance Equivalent can be used for ranking different stainless steels with regard to their pitting resistance. The PRE number is defined as:

PRE = % Cr + 3.3 x % Mo + 16 x % N

Table 2. PRE values for Alleima® 3R64 and some other alloys. Typical values unless otherwise stated

| Alloy | 3R64 | ASTM 316L1) | Alloy 825 | 904L | SAF 2205 |

|---|---|---|---|---|---|

| PRE | 29 | 24 | 31 | 34 | >35 |

1) 2.1 % Mo

Thus Alleima® 3R64 is resistant against pitting corrosion at higher temperatures and/or higher chloride concentrations than is the case for ASTM 316L.

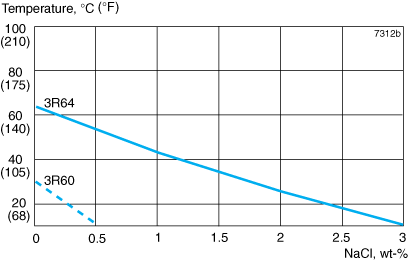

Figure 1. Crevice corrosion resistance of Alleima® 3R64 and 3R60.

The same ranking of alloys can be applied for the crevice corrosion resistance. However, crevice corrosion is to be expected at significantly lower temperatures, than is the case for pitting corrosion. Figure 1 demonstrates the better crevice corrosion resistance of Alleima® 3R64 vs. 3R60 (ASTM 316L with 2.6% Mo, EN 1.4435) after 2 months exposure in chloride solutions.

Stress corrosion cracking

Austenitic steels are susceptible to stress corrosion cracking. This may occur at temperatures above about 60°C (140°F) if the steel is subjected to tensile stresses and at the same time comes into contact with certain solutions, particularly those containing chlorides. Such service conditions should therefore be avoided. Conditions when plants are shut down must also be considered, as the condensates which are then formed can develop a chloride content that leads to both stress corrosion cracking and pitting.

In applications demanding high resistance to stress corrosion cracking, austenitic-ferritic steels, such as SAF 2304 or SAF 2205 are recommended. See data sheets S-1871-ENG or S-1874-ENG.

Forms of supply

Seamless tube and pipe

Seamless tube and pipe in Alleima® 3R64 is supplied in dimensions up to 260 mm outside diameter in the solution annealed and white-pickled condition or solution annealed in a bright-annealing process.

Other forms of supply

Alleima® 3R64 is also supplied in forms of:

- Welded tube and pipe

- Fittings and flanges

Further details concerning sizes and finishes are available on request.

Heat treatment

The tubes are delivered in heat treated condition. If additional heat treatment is needed after further processing the following is recommended.

Stress relieving

850–950°C (1560–1740°F), 10-15 min, cooling in air.

Solution annealing

1000–1100°C (1830–2010°F), 10-30 min, cooling in air or water.

Mechanical properties

For tube and pipe with a wall thickness greater than 10 mm (0.4 in.) the proof strength may fall short of the stated values by about 10 MPa (1.4 ksi).

At 20°C (68°F)

| Proof strength | Tensile strength | Elong. | Hardness | |

|---|---|---|---|---|

| Rp0.2a | Rp1.0a | Rm | Ab | Vickers |

| MPa | MPa | MPa | % | |

| approx. | ||||

| ≥220 | ≥250 | 515-690 | ≥35 | 155 |

| Proof strength | Tensile strength | Elong. | Hardness | |

|---|---|---|---|---|

| Rp0.2a | Rp1.0a | Rm | Ab | Vickers |

| ksi | ksi | ksi | % | |

| approx. | ||||

| ≥32 | ≥36 | 75-100 | ≥35 | 155 |

1 MPa = 1 N/mm2

a) Rp0.2 and Rp1.0 correspond to 0.2% offset and 1.0% offset yield strength, respectively.

b) Based on L0 = 5.65 ÖS0 where L0 is the original gauge length and S0 the original cross-section area.

Impact strength

Due to its austenitic microstructure, Alleima® 3R64 has very good impact strength both at room temperature and at cryogenic temperatures.

Tests have demonstrated that the steel fulfils the requirements according to the European standards EN 13445-2 (UFPV-2) ( (min. 60 J (44 ft-lb) at -270 oC (-455 oF)) and EN 10216-5 (min. 60 J (44 ft-lb) at -196 oC (-320oF).

At high temperatures

| Temperature | Proof strength | |

|---|---|---|

| °C | Rp0.2a | Rp1.0a |

| MPa | MPa | |

| min. | min. | |

| 50 | 196 | 221 |

| 100 | 172 | 197 |

| 150 | 155 | 180 |

| 200 | 144 | 169 |

| 250 | 136 | 161 |

| 300 | 129 | 154 |

| 350 | 123 | 148 |

| 400 | 119 | 144 |

| 450 | 115 | 140 |

| 500 | 110 | 135 |

| Temperature | Proof strength | |

|---|---|---|

| °F | Rp0.2a | Rp1.0a |

| MPa | ksi | |

| min. | min. | |

| 200 | 25.4 | 29.0 |

| 400 | 20.8 | 24.4 |

| 600 | 18.4 | 22.1 |

| 800 | 17.0 | 20.6 |

| 1000 | 15.4 | 19.0 |

Physical properties

Density: 8.0 g/cm3, 0.29 lb/in3

| Temperature, °C | W/m °C | Temperature, °F | Btu/ft h °F |

|---|---|---|---|

| 20 | 14 | 68 | 8 |

| 100 | 15 | 200 | 8.5 |

| 200 | 17 | 400 | 10 |

| 300 | 18 | 600 | 10.5 |

| 400 | 20 | 800 | 11.5 |

| 500 | 21 | 1000 | 12.5 |

| 600 | 23 | 1100 | 13 |

| Temperature, °C | J/kg °C | Temperature, °F | Btu/lb °F |

|---|---|---|---|

| 20 | 485 | 68 | 0.11 |

| 100 | 500 | 200 | 0.12 |

| 200 | 515 | 400 | 0.12 |

| 300 | 525 | 600 | 0.13 |

| 400 | 540 | 800 | 0.13 |

| 500 | 555 | 1000 | 0.13 |

| 600 | 575 | 1100 | 0.14 |

| Temperature, °C | Per °C | Temperature, °F | Per °F |

|---|---|---|---|

| 30-100 | 16.5 | 86-200 | 9.5 |

| 30-200 | 17 | 86-400 | 9.5 |

| 30-300 | 17.5 | 86-600 | 10 |

| 30-400 | 18 | 86-800 | 10 |

| 30-500 | 18 | 86-1000 | 10 |

| 30-600 | 18 | 86-1200 | 10.5 |

| 30-700 | 18.5 | 86-1400 | 10.5 |

1) Mean values in temperature ranges (x10-6)

| Temperature, °C | MPa | Temperature, °F | ksi |

|---|---|---|---|

| 20 | 200 | 68 | 29.0 |

| 100 | 194 | 200 | 28.2 |

| 200 | 186 | 400 | 26.9 |

| 300 | 179 | 600 | 25.8 |

| 400 | 172 | 800 | 24.7 |

| 500 | 165 | 1000 | 23.5 |

1) (X103)

Welding

The weldability of Alleima® 3R64 is good. Welding must be carried out without preheating and subsequent heat treatment is normally not required. Suitable methods of fusion welding are manual metal-arc welding (MMA/SMAW) and gas-shielded arc welding, with the TIG/GTAW method as first choice.

For Alleima® 3R64, heat input of <1.5 kJ/mm and interpass temperature of <100°C (210°F) are recommended.

Recommended filler metals

TIG/GTAW or MIG/GMAW welding

ISO 14343 S 19 13 4 L / AWS A5.9 ER317L (e.g. Exaton 19.13.4.L)

MMA/SMAW welding

ISO 3581 E 19 13 4 L R / AWS A5.4 E317L-16 (e.g. Exaton 19.13.4.LR)

ISO 14343 S 19 13 4 L / AWS A5.9 ER317L (e.g. Exaton 19.13.4.L) wire or strip electrodes are recommended for overlay welding of tube sheets and high-pressure vessels in cases where corrosion resistance, equal to that of Sandvik 3R64, is required.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.