When making metallurgical upgrades in the petroleum refining and chemical process industries, there are many alloy options to choose from. Striking a good balance between corrosion performance and project economics is vital in material selection.

Traditionally, when 300 series austenitic grades are no longer an option, users then have the option to use duplex stainless steel (DSS) grades, provided the operating temperature of the process is within the acceptable limits for this family of alloys, or to use super austenitic grades. However, in severely corrosive environments, the available alloy options become limited, and the solution is typically found in traditional and costly nickel alloys like Alloy 625 and Alloy C-276.

Sanicro® 35 is a 27% Cr, 35% Ni, 6.5% Mo recently developed high-performance austenitic stainless steel with a pitting resistance equivalent number (PRE) of 52 that approaches nickel-based alloy performance in certain environments. This article explores the alloy’s performance in comparison to austenitic and nickel-based alloys in various process environments by using standardized testing methods such as ASTM G48, modified ASTM G150, ammonium chloride (NH4Cl), ammonium bisulfide (NH4HS), as well as its pitting and stress corrosion cracking resistance in renewables lipids feedstock pre-treatment conditions.

Introduction

Sanicro® 35 is structurally stable, offers localized corrosion resistance, and outperforms conventional 6Mo grades. It also has the desirable corrosion resistance of high nickel grades in chloride-bearing environments. The PREN is used to rank the pitting corrosion resistance based on the chemical compositions, and a commonly used formula is PREN= %Cr+3.3%Mo+16%N. Sanicro® 35 is classified as super austenitic stainless steel due to its high PREN value of approximately 52 [1]. This material was designed to bridge the gaps between duplex stainless steel or austenitic grades and nickel alloys. Sanicro® 35 is an alternative material for applications in demanding environments, such as seawater coolers [2], high chloride, and high-temperature processes. Sanicro® 35 produced in sheet, plate, bar, seamless tube, and pipe is approved by the ASME Boiler and Pressure Vessel Code, Section VIII, Division I and II, under Code Case 2982-2 up to 450°C (842 °F).

It provides easy fabrication when it comes to welding. Sanicro® 35 requires no pre-heating or post-weld heat treatment due to its high structural stability and is not prone to form intermetallic phases. It also offers formability, comparable to other 300 stainless steels and super-austenitic grades, which allows cold bending to a tight bending ratio.

Corrosion Properties

The combination of high contents of nickel, chromium, and molybdenum in Sanicro® 35 offers resistance to general corrosion in many common acids, such as hydrochloric acid, sulfuric acid, nitric acid, phosphoric acid, caustic solutions, and organic acids [3].

Pitting and Crevice Corrosion

Table 1 compares the chemical composition of different austenitic and nickel alloys.

Table 1 – Chemical composition of the grades

| Grade | C | Cr | Ni | Mo | N | Fe | Others | |

| Type | UNS | |||||||

| 316L | S31603 | 0.04 | 17.2 | 10.1 | 2.1 | - | Bal. | - |

| 904L | N08904 | 0.01 | 19.8 | 24.2 | 4.3 | - | Bal. | 1.4Cu |

| 254 SMO | S31254 | 0.01 | 20 | 18 | 6.1 | 0.2 | Bal. | Cu |

| Sanicro®35 | N08935 | 0.02 | 27.0 | 35.0 | 6.5 | 0.30 | Bal. | Cu |

| 6XN |

N08926/ N08367 |

0.01 | 20.5 | 24.8 | 6.5 | 0.2 | Bal. | Cu |

| Alloy 825 | N08825 | 0.01 | 23 | 39 | 3.2 | - | Bal. | Cu, Ti |

| 2507 | S32750 | 0.02 | 25.0 | 7.0 | 4.0 | 0.27 | Bal. | - |

| Alloy 31 | N08031 | 0.015 | 27.0 | 31.0 | 6.5 | 0.2 | Bal. | 2Mn, Cu |

| Alloy 625 | N06625 | 0.03 | 22.0 | Bal. | 9.0 | - | <5.0 | 3.5 Nb+Ta |

| Alloy C276 | N10276 | 0.01 | 16.0 | Bal. | 16.0 | - | 5.0 | 3.5W, 2.5Co |

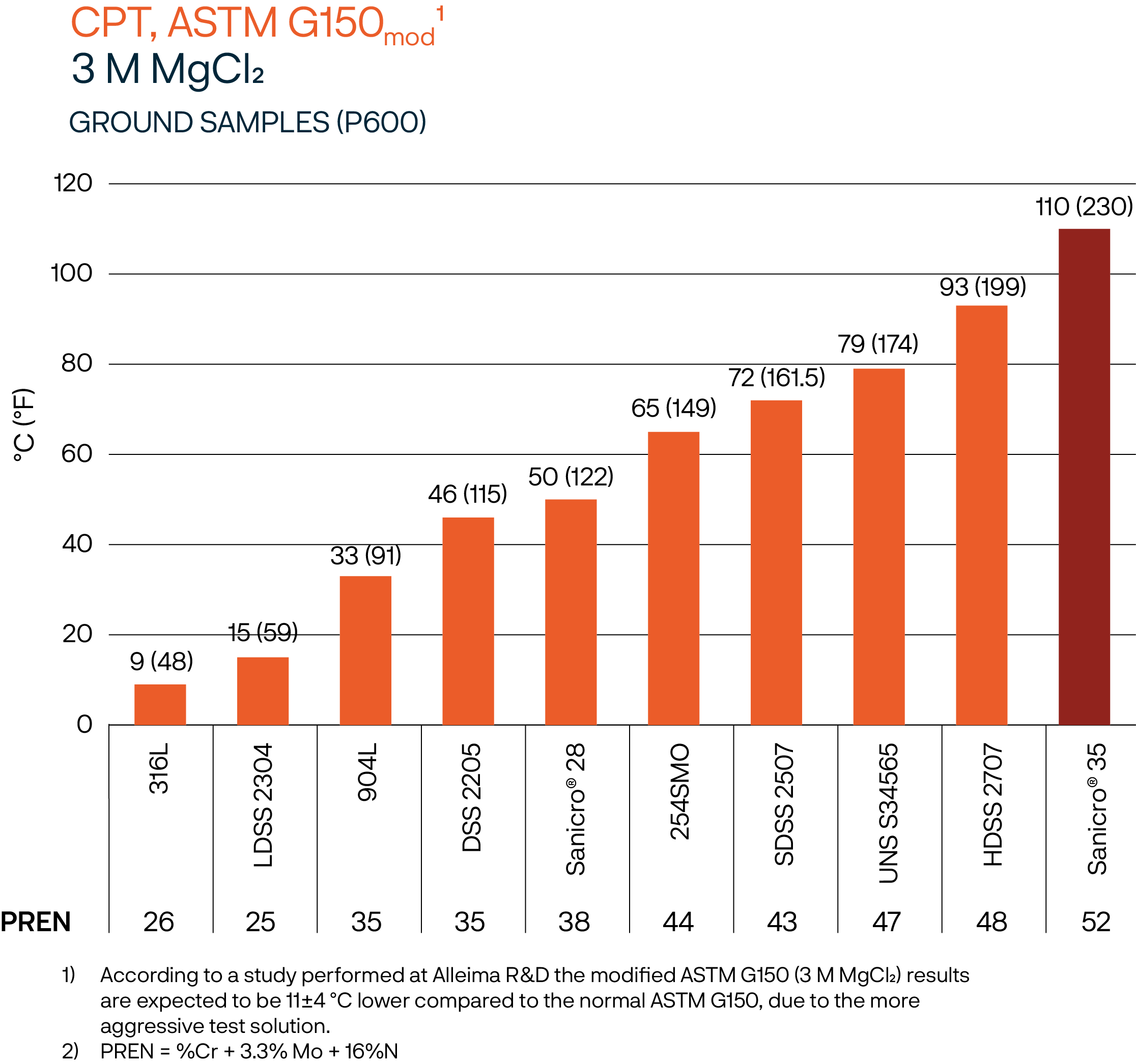

When performing accelerated corrosion tests in ASTM G150 with a modified and more aggressive solution of 3M MgCl2, it is demonstrated that, given its highly alloyed composition and PRE number, Sanicro®35 has superior resistance to pitting corrosion and crevice corrosion in comparison to 6 Mo grades, duplexes, other types of stainless steel, or even nickel-based alloys, as shown in Figures 1, 2, and 3.

Figure 1: CPT- values for Sanicro® 35 and other alloys performed by modified ASTM G150.

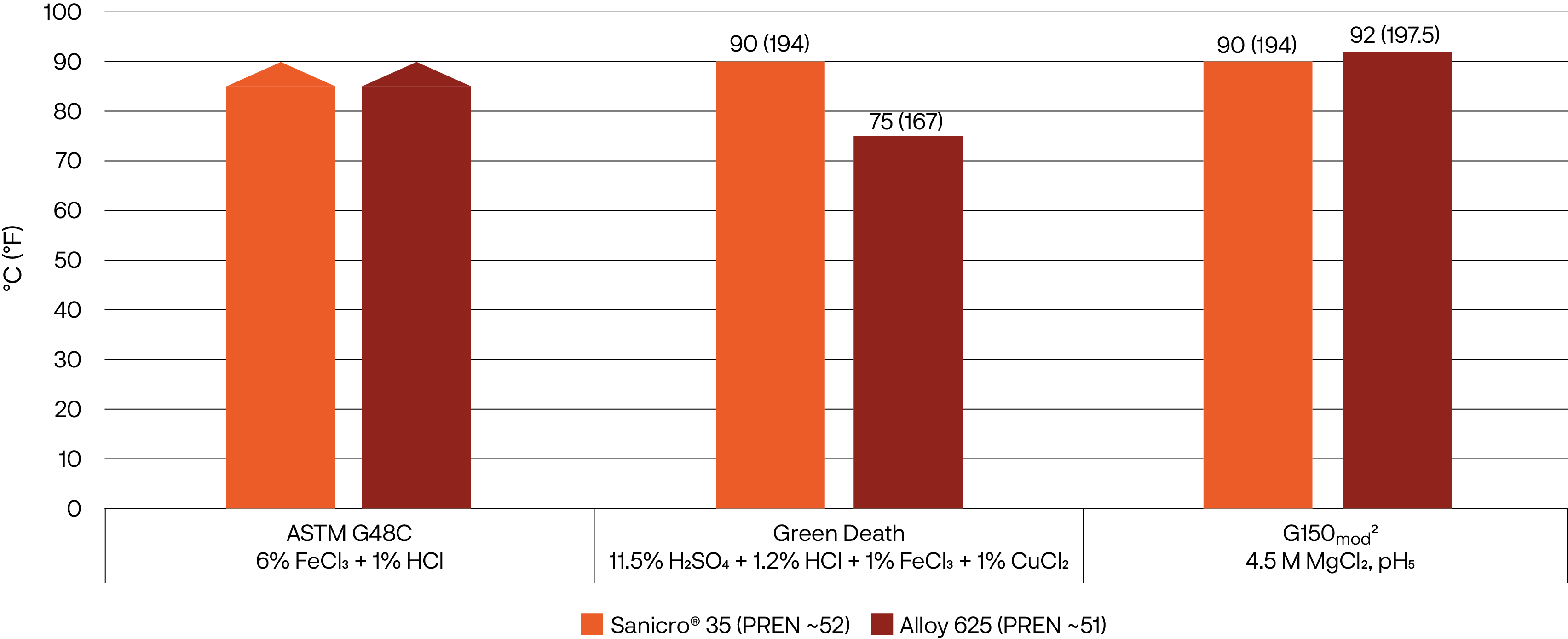

Figure 2 compares the critical pitting temperature (CPT) of Sanicro® 35 and Alloy 625. This chart shows the results from testing according to ASTM G48 Method C, which has a testing temperature limit of 85 °C, green death, and modified and more aggressive 4.5M MgCl2 ASTM G150 solution.

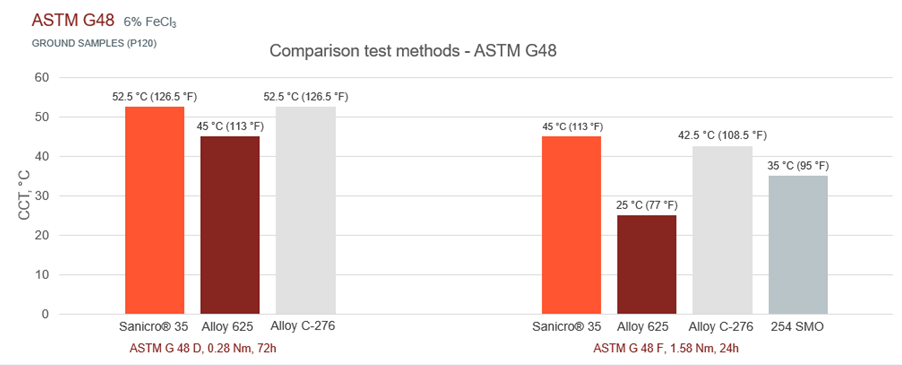

Figure 3 shows the crevice critical temperature (CCT) for Sanicro® 35 and other alloys. Sanicro® 35 can be an alternative in applications where seawater or chloride environments are present. Sanicro® 35 exhibited superior localized corrosion resistance compared to austenitic . It also provided comparable corrosion resistance to Alloy 625 and Alloy C-276 while being a more cost-effective solution.

Figure 2: CPT-values of Sanicro® 35 compared to alloy 625 using ASTM G48 method C, green Death solution, and modified ASTM G150.

Figure 3: CCT-values for Sanicro® 35 compared to other alloys using ASTM G 48 Method D and F.

Figures 1, 2, and 3 prove that Sanicro® 35 is more resistant to localized corrosion than austenitic stainless steels. The data in these figures also confirms that the localized corrosion resistance of Sanicro® 35 is comparable or superior to two of the most widely used nickel alloys (Alloy 625 and Alloy C-276) in several standardized laboratory corrosion tests.

Stress Corrosion Cracking (SCC)

Standard austenitic steels of the ASTM 316 type are susceptible to chloride-induced stress corrosion cracking (SCC) in chloride-bearing solutions at temperatures above 60°C (140°F). However, SCC susceptibility declines with increasing nickel content of the alloy. Additionally, a Chromium content of over 20% can also be beneficial. Sanicro® 35 has excellent resistance to SCC, as seen in Table 2.

Table 2 – Results of SCC resistance. 24h U-bend test in boiling 45% MgCl2 at 155°C. Number of cracked specimens out of three tested.

| Grade | Cracked Samples |

| 254 SMO | 3/3 |

| 6XN | 3/3 |

| Sanicro® 35 | 1/3 |

| Alloy 825 | 2/3 |

| Alloy 31 | 3/3 |

Renewable diesel feedstock contains contaminants, such as phosphorus, metals, and chlorides, that call for a feedstock pre-treatment process that involves high temperatures, pressures, and an acidic environment. In addition, these feedstocks are rich in such free fatty acids that lead to a highly corrosive environment with a high total acid number (TAN). All of these represent a challenge for the material of construction of renewable pretreatment units that require improved metallurgical solutions. Corrosion concerns include the potential for chloride stress cracking at high temperatures and high acid concentrations. Sanicro® 35 has been tested in water with pH=2 using citric acid, 500 ppm chlorides, and T=275 °C (527 °F), proving to be resistant to corrosion and cracking under these conditions.

Corrosion in Refineries

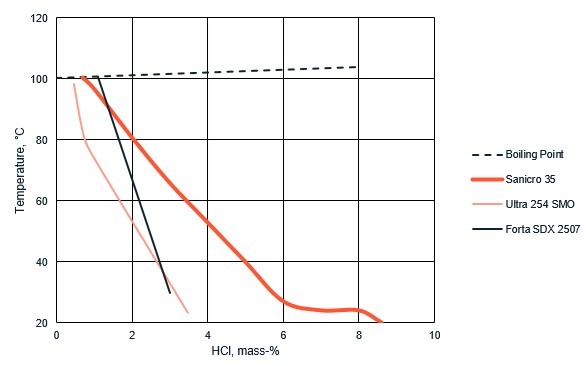

In refineries, the distillation tower overhead systems of the crude distillation unit can be susceptible to corrosion due to hydrochloric acid when the equipment operates at or below the water dewpoint temperatures. Sanicro® 35 performs well in hydrochloric acid and can be used in heat exchangers that may encounter dew point corrosion from condensing hydrochloric acid [4,5]. The pH level of the starting condensate is around 1 or 2, which varies based on the quantity of HCl present in the distillation tower’s overheating stream [6,7]. The iso-corrosion diagram shown in Figure 4 demonstrates that Sanicro 35 is a suitable alloy for situations where such conditions may occur.

Figure 4: Iso-corrosion in hydrochloric acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy) [3].

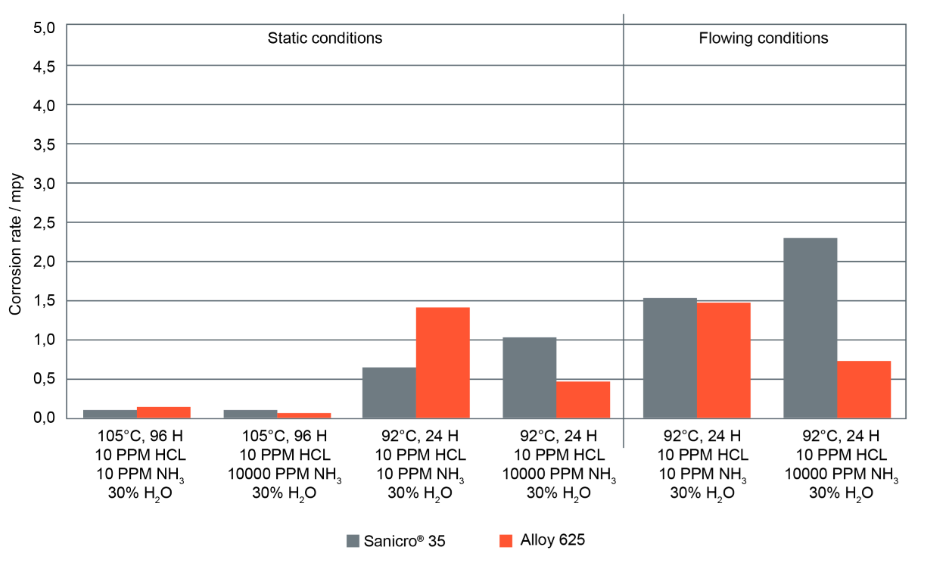

A common cause of corrosion in refinery applications such as overhead condensers, hydrotreater shell and tube heat exchangers, and air coolers is fouling from ammonium chloride (NH4Cl). Ammonium chloride can cause under-deposit corrosion, pitting corrosion, and stress corrosion cracking. Sanicro® 35 has been shown in advanced laboratory testing to have the same resistance to this kind of corrosion as Alloy 625 (see Figures 5 and 6).

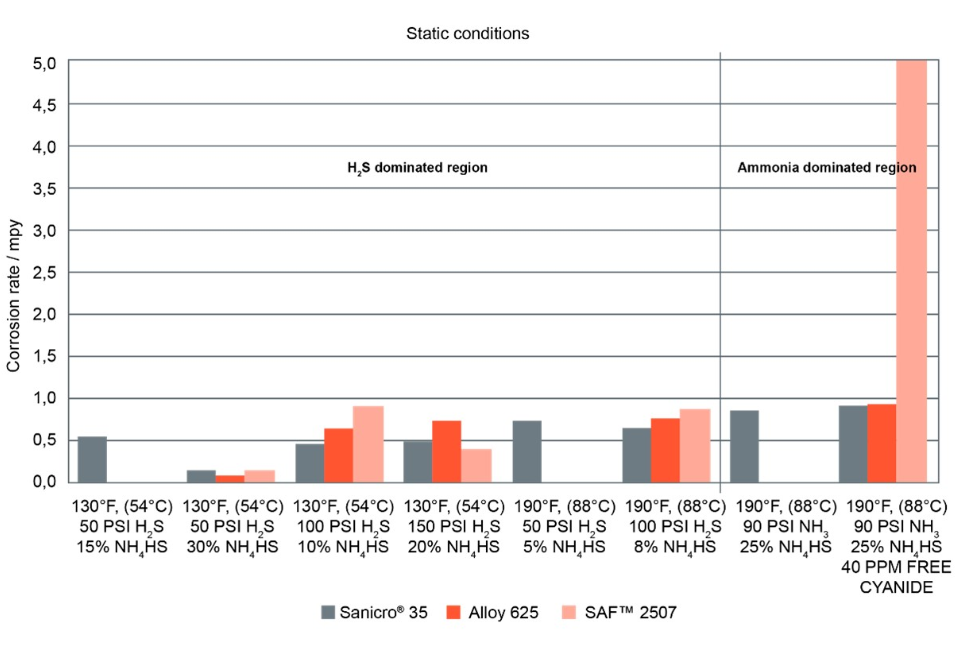

Figure 5 shows a simulation of the ammonium chloride under deposit corrosion in crude distillation overhead condensers, where Sanicro® 35 was shown to be a cost-efficient alternative to alloy 625 for overhead condensers in refinery applications [6]. Other challenges particularly predominant in the effluent from the hydrotreater reactor are chloride and sulfide stress corrosion cracking and pitting corrosion of lower alloyed stainless steels due to the presence of water, hydrogen sulfide, ammonia, carbon dioxide, and chlorides. Upon cooling, an acidic water phase with chlorides is formed, which can cause cracks and leaks that potentially lead to fires or explosions if hydrocarbons are released into the atmosphere. Typical heat exchangers where corrosion is a concern are Feed/effluent heat exchangers, Reactor effluent air coolers (REACs), Water-cooled heat exchangers, and Pre-heat trains. Traditional refinery heat exchangers use carbon steel tubes, TP321/347, or Alloy 825, but these may not be suitable, particularly when processing renewable feedstock. Figure 6 shows corrosion tests similar to the ammonium bisulfide (NH4HS) in reactor effluent air coolers (REAC) service [8]. Sanicro® 35 has excellent corrosion resistance to ammonium bisulfide corrosion. In the case of chlorides, it has much better resistance toward pitting and crevice corrosion than Alloy 825. Sanicro® 35 has proven excellent corrosion resistance to both ammonium chloride and ammonium bisulfide corrosion.

Figure 5: Corrosion rates for under-deposit and acidic aqueous corrosion performed at Honeywell, Houston, TX, USA.

Figure 6: Corrosion rate for static flow-through coupons in refinery sour services.

Conclusions

Sanicro® 35 is an alternative material for applications in demanding environments, such as seawater coolers, high chloride, and acidic conditions. With its high yield strength, excellent pitting, crevice, and stress corrosion cracking resistance combined with good structure stability and weldability, Sanicro® 35 is suitable for the refinery and chemical industry.

References

[1] S. Li, Precipitation behavior of the super austenitic stainless steel SANICRO® 35 and the effect on impact toughness and pitting corrosion resistance, M.Sc. Thesis, School of Industrial Engineering and Management, 2022.

[2] J. Eidhagen, R.M. Öhnfeldt, U. Kivisäkk, UNS N08935-a new alloy for seawater applications, in: Corrosion 2021, Paper No. 16573, 2021.

[3] B. Helmersson, M. Almén, Uniform Corrosion Characterization of UNS N08935, in: AMPP 2023, Paper No. 19294, 2023.

[4] D. Gullberg, R.M. Öhnfeldt, A.R. Yhr, Corrosion properties of Alloy 35Mo, new PREN 52 alloy for refinery and chemical industry, in: Corrosion 2020, 2020: pp. 1–9.

[5] D. Gullberg, R. Mattsson Öhnfeldt, A.R. Yhr, Corrosion properties of Alloy 35Mo, new PREN 52 alloy for refinery and chemical industry, in: Corrosion 2020, Paper No. C2020-14769, 2020.

[6] J. Höwing, K. Picker, Corrosion Properties of UNS N08935 In Crude Distillation Unit Overhead Service Conditions, Corrosion 2021 (2021).

[7] N. International, Crude Distillation Unit — Distillation Tower Overhead System Corrosion, NACE International Publication 34109 (2009) 1–85.

[8] K. Picker, J. Höwing, Corrosion Behavior of UNS N08935 In Refinery Sour Water Services, Corrosion 2021 (2021).