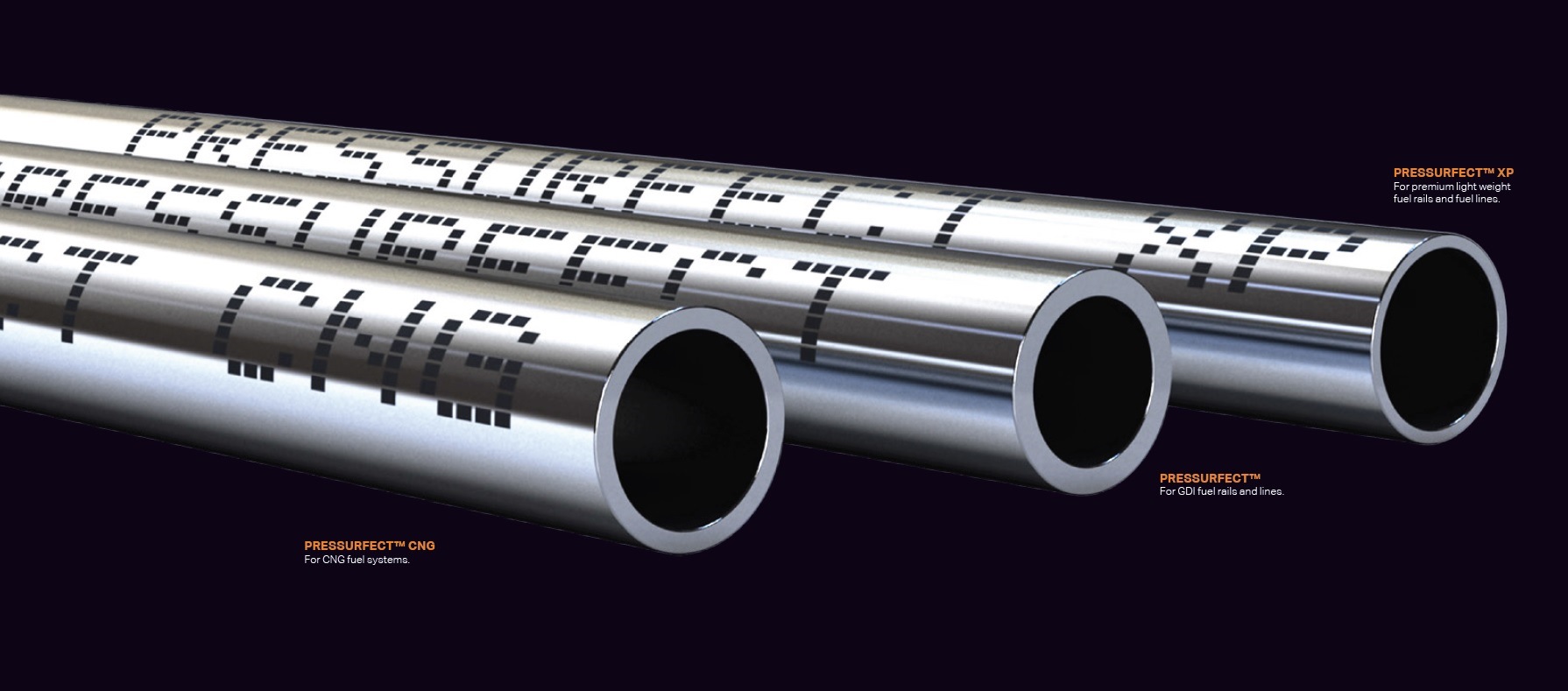

As the market leader for CNG tubing in India for several decades now, Alleima knows what it takes to meet customers’ needs. Our range of Pressurfect® tubing for the automotive industry enables safer injection pressure in CNG fuel management systems, allowing the engines to maintain high performance with lower fuel consumption and lower emissions. Pressurfect® CNG, our premium, dual-standard (ASTM 316/316L) seamless tube, is strong, easy to bend and fabricate, and allows for leak-free CNG fuel lines.

What should you consider when selecting tubing for your CNG vehicles? Here are some key points that you should know about.

Raw material source

This is most important as the raw material largely determines the quality of the final product. Integrating steel plant operations so the manufacturer has control over every step of production ensures a high-quality product finish every time.

Chemical properties

Pitting corrosion is the most common type of corrosion on stainless steel tubes. A suitable pitting resistance equivalent (PRE) number of 26 or higher is required for the material.

The material composition that has become the benchmark for CNG high-pressure tubing is:

- Less than 0.025% carbon for improved corrosion resistance

- More than 2.5% molybdenum for better pitting corrosion resistance and extra strength when increased in proportion to the amount of nickel

- More than 13% nickel for increased toughness and strength. Nickel helps form a passive layer on the steel, which makes it stainless

- 02 to 0.04 % nitrogen increases corrosion resistance and tube strength

Manufacturing process

This also plays a vital role in determining the quality of the end product. The latest process for tube manufacturing is extrusion followed by cold pilgering or drawing to deliver better quality, cleaner steel.

Heat treatment

The mechanical properties of the end product depend on this process, so experience is essential. Bright annealing, or heat treatment under controlled conditions (specifically without oxygen), to avoid acid bath, and a smooth surface is a standard process.

Non-destructive Tests

Eddy Current Testing (ECT) is a form of non-destructive test used for steel tubing. ECT verifies the most minute defects that might occur during production and is done to ensure that there are no surface defects on the inner or outer surfaces of the tubing. This test is normally done as part of the standard ASTM A450 and should be mandatory for all of the tubing.

Tolerances

Tighter tolerances of +/- 0.08 mm for the outer diameter (OD) support improve swaging, easier installation, and reduce any possibility of leaks.

Surface roughness

Better surface roughness on the OD helps achieve a leak-free joint. This supports safer working conditions and improves productivity. Maximum surface roughness of Ra 1µm enables a better swaging action.

Quality

What do you look for in a producer of seamless tubes? One that produces a comprehensive range of premium grades that meet ASTM and EN standards, ensures stock availability to meet on-time deliveries, and consistently deliver quality standards like corrosion resistance, dimensional tolerance, and hardness control.

At Alleima, we give you the Alleima Peace of Mind Standard, one that takes a six-star approach to meet your needs, however specific they are. All of our tubes also go through the “9 step cleaning process” to give you the peace of mind of receiving clean tubing to safeguard your trouble-free operations.

Experience

Experience is crucial for a critical application like high-pressure CNG. The vendor should have a solid track record in supplying tubing to the Industry. Alleima has been serving the global automotive industry for over 70 years and has supplied over 5 million meters of material for high-pressure tubing application to the natural gas vehicle/city gas distribution (CGD) industry. We have the experience, and the expertise to work with you to meet your challenges and identify opportunities for improvements and enhancements.