Alleima® 20AP is a hardenable, free-cutting carbon steel medical wire characterized by excellent machinability. The grade has high hardness, high wear resistance and exceptional dimensional stability after hardening.

Applications

Alleima® 20AP is used for dental applications such as dental burrs and drills.

Chemical composition (nominal) %

| C | Si | Mn | P | S | Pb |

|---|---|---|---|---|---|

| 1.0 | 0.2 | 0.4 | ≤0.030 | 0.05 | 0.2 |

Forms of supply

| Forms of supply/ finishes | Diameter |

Cu-Sn coating | Standard tolerance | Length |

|---|---|---|---|---|

| mm | m | |||

| Wire in coils | ||||

| Drawn | 0.80-1.60 | D4 | - | |

| 1.60-2.50 | D4 | - | ||

| Straightened wire | ||||

| Drawn | 0.80-1.15 | D4 | 2 | |

| 1.15-2.00 | D4 | 2 | ||

| 2.00-2.50 | D3 | 2 | ||

| Drawn/ground | 2.00-3.00 | h7 | 2 | |

| 3.00-6.00 | h7 | 3 | ||

| 6.00-12.00 | h7 | 3 | ||

Other sizes on request.

Ovality: For D1 and D2, max. 50% of the tolerance width, for D3 max. 25% of the tolerance width.

Mechanical properties

| Forms of supply/Finishes | Diameter | Tensile strength | Proof strength | Elongation |

|---|---|---|---|---|

| mm | Rm1) | Rp0.21) 2) | A 1)3) | |

| MPa | MPa | % | ||

| Wire in coils | 0.80-1.60 | 770 | ||

| Drawn | 1.60-2.50 | 720 | 770 | 4 |

| Straightened wire | 0.80-1.15 | >980 | 720 | 7 |

| Drawn | 1.15-2.00 | >920 | >910 | 3 |

| Drawn/ground | 2.00-2.50 | >900 | >850 | 5 |

| 2.00-3.00 | >920 | >830 | 7 | |

| 3.00-6.00 | 810 | >850 | 6 | |

| 6.00-12.00 | 750 | 670 | 10 | |

| 620 | 12 |

1) Nominal values. Other properties on request.

2) Rp0.2 and elongation values are given for information only.

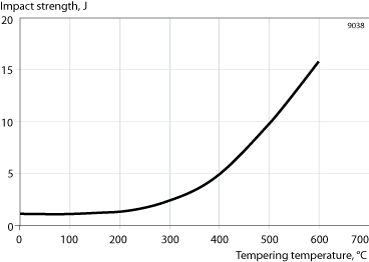

Impact strength

Quenching time and temperature is dependent on material size, the specimens for impact strength are larger than standard wire.

Table of impact strength for Exera® 20AP, hardened and quenched condition (soaking temperature 800°C and soaking time 10 min, tempering time is 30 min)

| Tempering temperature, °C | Impact strength, J |

|---|---|

| 200 | 1.3 |

| 300 | 2.0 |

| 400 | 7.3 |

| 500 | 10.0 |

| 600 | 17.0 |

Figure 1. Impact strength after recommended hardening procedures, valid for all dimensions.

Soaking time 30 minutes. Standard Charpy-V specimens at 20oC.

Physical properties

Density annealed 7.8 g/cm3, 0.28 lb/in3

Resistivity

Cold drawn, 0.18 µΩm

Heat treated, 0.21 µΩm

| Temperature, °C | 20-100 | 20-200 | 20-300 |

|---|---|---|---|

| Cold drawn | 11.5 | 11.5 | 12.5 |

| Heat treated | 11.5 | 12.0 | 12.5 |

1) Mean values in temperature ranges (x10-6)

Exera® 20AP is a magnetic material.

Heat treatment

Soft-annealing

When required, soft-annealing should be conducted for a period of one hour at a temperature of 650 - 680oC.

| Diameter | Temperature | Soaking time | Quenching |

|---|---|---|---|

| mm | oC | approx. min. | |

| ≤5 | 800 - 820 | 3 - 6 | in oil at 50oC |

| > 5 | 790 - 810 | 6 - 10 | in water |

The smaller the diameter, the shorter the soaking time. To avoid oxidation and decarburization, hardening should be conducted in a protective gas atmosphere using nitrogen, argon or a vacuum.

Contact Alleima for further advice.

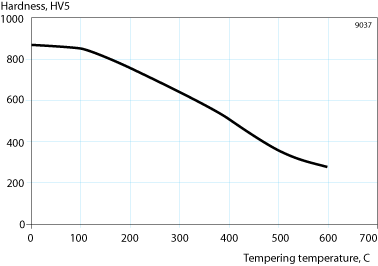

Prolonged service at elevated temperatures causes decreased hardness when used in the hardened and tempered condition. See also "Impact strength".

| Temperature, oC | 100 - 600 |

|---|---|

| Tempering time, min | 30 - 60 |

The core of the material needs a tempering time of at least 30 minutes. To reduce the risk of cracking, tempering should be conducted immediately after hardening. The heating rate should not be too high, particularly in the case of intricately shaped components.

Hardness

Figure 2. Hardness after recommended hardening procedures, valid for all dimensions.

Soaking time 30 minutes.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.