There are around two billion residential air conditioners (RAC) in use around the world today. If they were all equipped with Freeflex™ and designed to meet the highest required level of energy efficiency, there would be up 10% less energy consumption from each unit, causing a butterfly effect of reduced CO2 emissions worldwide.

Freeflex™, for more energy-efficient air conditioners Skip to content

As global temperatures soar, more and more people are using air conditioners to keep cool, or even just to survive. The International Energy Agency (IEA) estimates there are now around two billion air conditioning units in operation around the world and expects that number to keep rising steeply.1

However, the IEA also says that air conditioning accounts for as much as 10% of our global electricity consumption.2 We’re caught in a feedback loop of rising temperatures causing a rising demand for cooling units, which in turn causes temperatures to keep climbing.

It’s clear that air conditioners won’t be disappearing any time soon, so the obvious way to help break that vicious circle is for air conditioner manufacturers to make the units more energy efficient. Alleima Freeflex™, a recently created compressor valve steel, can support compressor manufacturers with this tough challenge. It’s the result of a five-year development process that has been designed to support AC compressor manufacturers in developing more efficient compressors.

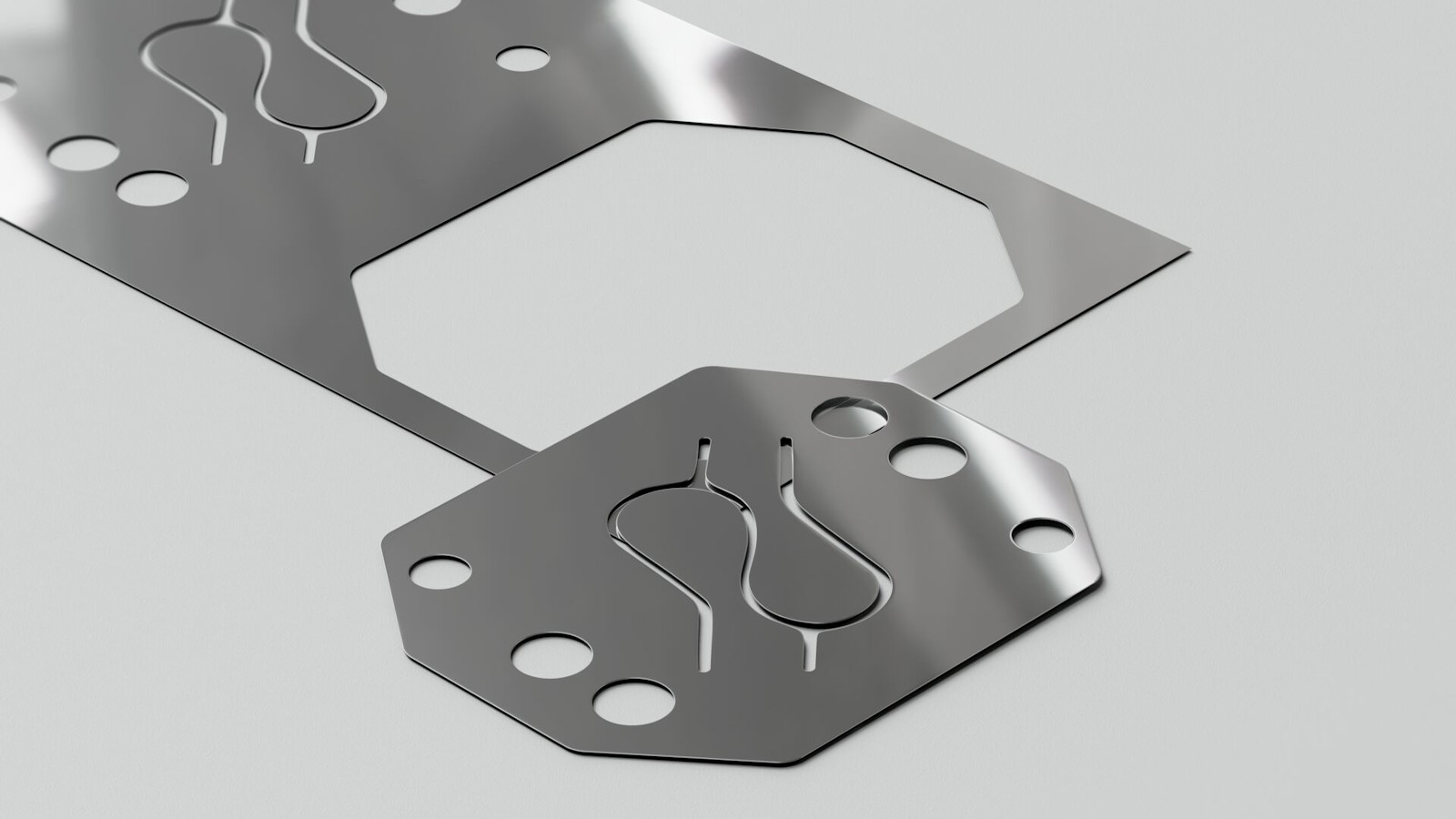

The compressor valve, a key to energy efficiency

The key to making air conditioning units use less energy is the compressor valve. This small part is often described as the heart of the air conditioning unit because it carries out the critical task of regulating the flow and pressure of the refrigerant in the cooling system.

“This is a high-precision strip steel that has to be able to withstand an enormous number of loads despite being a very thin piece of metal that’s pitching up and down up to 200 times a second,” says Stefan Jonsson, a Product Specialist at Alleima who has been deeply involved in the FreeflexTM development process.  Stefan Johansson, Product specialist

Stefan Johansson, Product specialist

“Standard compressors run at 50 Hz frequency but with inverter technology the operational frequencies are going up to 150 Hz. This puts enormous requirements on the steel especially considering that the unit has a warranty of 10 years.”

A more fatigue-resistant compressor valve steel allows valves to withstand higher dynamic loads which can be used in designing more energy-efficient air conditioning unit designs, and a more pliable material allows manufacturers flexibility in their designs to achieve more output from the unit for less energy

And that’s what Alleima has done. Freeflex compressor valve steel has been optimized for air conditioning units, although it can also be used in heat pumps and refrigerators or almost any type of compressor. With a required energy saving of up to 30% in some segments, FreeflexTM has a huge role to play in reducing CO2 emissions from compressor applications.

How Freeflex helps save energy

The development of Freeflex began in response to feedback from air conditioner manufacturers in China, whose burgeoning middle class has made it the world’s number one air conditioning market. There are now more than 500 million AC units in the country and counting, while most of the world’s major air conditioning manufacturers are Chinese.

The Chinese Government set the country’s compressor manufacturers ambitious targets to reduce energy consumption by 20% in 2030 vs 2025. “The industry must achieve this; they’ll live or die by it,” says Jonsson. He adds that even before the government’s legislation some of those key players in the industry had already been asking Alleima for a steel that could help them reduce their energy consumption and make them more efficient.

FreeflexTM is a hardened and tempered martensitic stainless compressor valve steel. It has a unique chemical composition alloyed with copper. Critical properties like microstructure and mechanical strength have been optimized, which gives it an increased ability to resist breaking compared to other alloys on the market.

“Freeflex in general has a higher fatigue strength than other compressor valve steels on the market. It has better wear resistance, better bending fatigue, and better impact fatigue resistance, which means that it lasts longer and is especially suited for the AC demand of keeping the noise at a low level,” says Jonsson.

“Freeflex in general has a higher fatigue strength than other compressor valve steels on the market. It has better wear resistance, better bending fatigue, and better impact fatigue resistance, which means that it lasts longer and is especially suited for the AC demand of keeping the noise at a low level,” says Jonsson.

“This gives the compressor manufacturer design freedom. The valves can be designed to be thinner, smaller, shorter, lighter but stronger, all of which helps them maximize the product’s energy efficiency.”

Growing interest and a ripple effect

There is growing interest in Freeflex™. Several major compressor manufacturers have been evaluating the alloy for new compressor designs with very promising results, especially within the AC segment.

“There is a lot of discussion around sustainability now and companies are focusing on it more and more. And with our compressor valve portfolio, like the Alleima Hiflex™, we have already supported the industry to develop more energy-efficient compressors over the past two decades.”

“We believe in this new material very strongly. There’s no doubt that Freeflex is making the difference here, and I would say that the Room Air Conditioning industry will face big problems in reaching the most recent legislation for energy reduction. The global energy reduction requirement puts us in a great position for the future because Freeflex is helping the industry to reach the high reduction targets.”

“We believe in this new material very strongly. There’s no doubt that Freeflex is making the difference here, and I would say that the Room Air Conditioning industry will face big problems in reaching the most recent legislation for energy reduction. The global energy reduction requirement puts us in a great position for the future because Freeflex is helping the industry to reach the high reduction targets.”

If the choices we make today affect our future, then it’s vital we choose materials that reduce the environmental impact of everyday products. As an enabler of energy efficiency, the widespread adoption of Alleima FreeflexTM compressor valve steel in air conditioners can begin a ripple effect of reducing global CO2 emissions.

1International Energy Agency Tracking space cooling

2International Energy Agency Global air conditioning market ripe for cool wind of change

Precision strip steel to push your possibilities

Alleima is your precision strip steel manufacturer. Learn about our product offering to find the optimal stainless steel for your application in our brochure.